A kind of high temperature base WC powder and its preparation method and application

A powder and high-temperature technology, which is applied in the field of high-temperature-based WC powder and its preparation, can solve problems such as difficulty in meeting production needs, insufficient stability of the preparation process, and many defects in grain tungsten powder, so as to reduce equipment investment and achieve good social and economic benefits , Good uniformity of powder particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

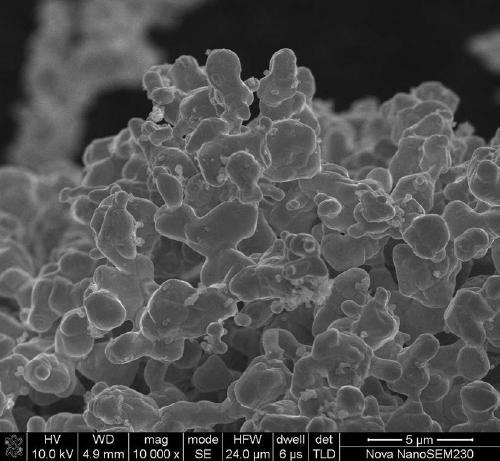

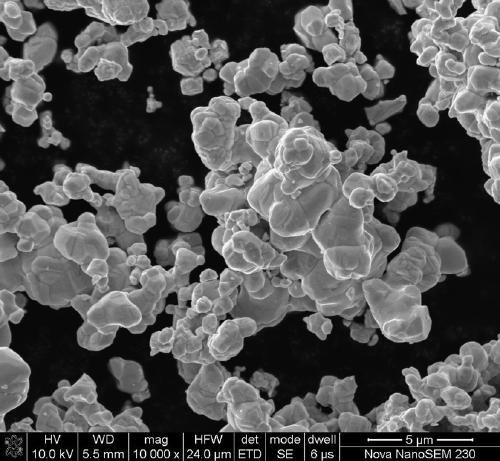

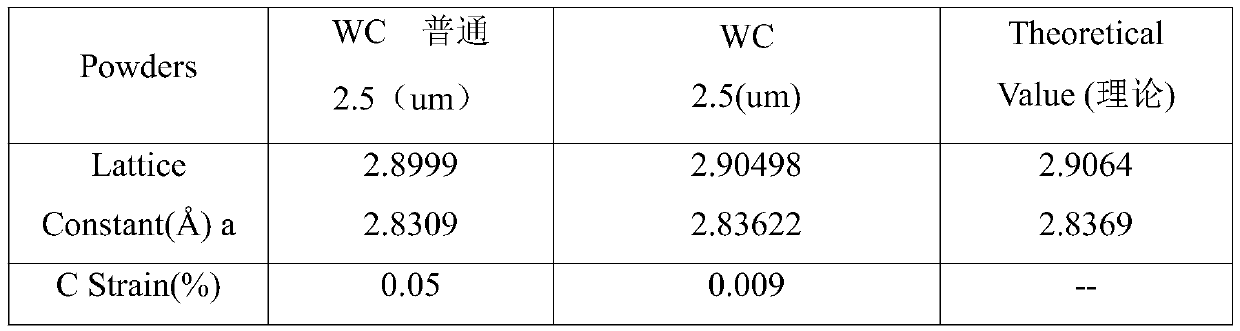

Image

Examples

Embodiment 1

[0031] The preparation method of the high-temperature-based WC powder of this embodiment, the specific operation steps are as follows:

[0032] S1. The FSSS particle size 12μm national standard zero grade WO 3 Carry out pre-grinding treatment for 4 hours in a double-cone mixer equipped with rubber-lined stainless steel balls, and add carbon black to carry out carbon matching once; after mixing evenly, a mixture 1 with a total carbon content of 15.5% is obtained in terms of mass fraction;

[0033] S2. The mixture 1 in step S1 is pressed and molded on a press, and reacted in a hydrogen-free carbonization furnace for hydrogen-free carbonization treatment. The reaction temperature is 1500°C, and the propulsion speed of mixture 1 is 15min / boat; the billet is obtained one;

[0034] S3. After crushing the blank material obtained in step S2, pass through a 100-mesh metal screen, and sample the obtained mixture to determine the total carbon and oxygen content; the total carbon of the ...

Embodiment 2

[0038] The preparation method of the high-temperature-based WC powder of this embodiment, the specific operation steps are as follows:

[0039] S1. The FSSS particle size 14μm national standard zero grade WO 3 Carry out pre-grinding treatment in a double-cone mixer equipped with rubber-lined stainless steel balls for 2 hours, and add carbon black for a carbon preparation; after mixing evenly, a mixture 1 with a total carbon content of 14.8% is obtained by mass fraction;

[0040] S2. The mixture one described in step S1 is pressed and molded, and reacted in a hydrogen-free carbonization furnace for hydrogen-free carbonization treatment. The reaction temperature is 1650°C, and the propulsion speed of the mixture one is 30min / boat; the billet one is obtained;

[0041] S3. After crushing the blank material obtained in step S2, pass through a 100-mesh metal screen, and sample the obtained mixture to determine the total carbon and oxygen content; the total carbon of the obtained mix...

Embodiment 3

[0045] The preparation method of the high-temperature-based WC powder of this embodiment, the specific operation steps are as follows:

[0046] S1. The FSSS particle size 17.5μm national standard zero grade WO 3 Carry out pre-grinding treatment in a double-cone mixer equipped with rubber-lined stainless steel balls for 2 hours, and add carbon black to carry out carbon matching once; after mixing evenly, a mixture 1 with a total carbon content of 13.8% is obtained in terms of mass fraction;

[0047] S2. The mixture one described in step S1 is pressed and molded, and reacted in a hydrogen-free carbonization furnace for hydrogen-free carbonization treatment. The reaction temperature is 1800°C, and the propulsion speed of the mixture one is 40min / boat; the blank material one is obtained;

[0048] S3. After crushing the blank material obtained in step S2, pass through a 100-mesh metal screen, and sample the obtained mixture to determine the total carbon and oxygen content; the tota...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com