Method for continuous neutralization and continuous water separation of polycondensation reaction solution during production of antioxidant TMQ

A polycondensation reaction and production process technology, applied in the field of green and environmentally friendly preparation technology, can solve problems such as affecting product stability, restricting process continuity, TMQ product blackening, etc. The effect of blending

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

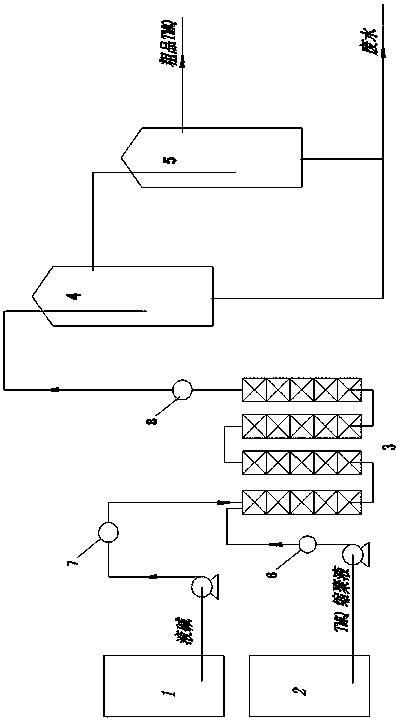

Image

Examples

Embodiment 1

[0035] (1) In the production process of anti-aging agent TMQ, aniline and acetone are condensed and polymerized under acidic conditions to obtain TMQ polycondensation reaction liquid, which is placed in the TMQ polycondensation reaction liquid storage tank for buffer storage;

[0036] (2) Use the distributed control system (DCS system) according to pH=7, control the flow meter and the regulating valve to initially mix the TMQ polycondensation reaction liquid and the liquid caustic soda (sodium hydroxide solution), and then import it into a set of static mixers for mixing. to obtain a mixed solution;

[0037] (3) After the mixed solution comes out of the static mixer, the online pH meter shows pH = 8, and the water is continuously divided through the primary water separator. The oil phase on the water separator overflows continuously to collect TMQ crude product, and the bottom water phase is continuous. Collect TMQ waste water. After testing, the pH of the anti-aging agent TM...

Embodiment 2

[0040] (1) In the production process of anti-aging agent TMQ such as "two-step method" or "one-step method", aniline and mesityl oxide are condensed and polymerized under acidic conditions to obtain the polycondensation reaction liquid of TMQ, which is placed in a storage tank, buffer storage;

[0041] (2) Use the distributed control system (DCS system) to preliminarily mix the TMQ polycondensation reaction liquid and liquid caustic soda (mixed solution of 10% sodium hydrogen phosphate and 25% sodium hydroxide) according to pH=8, control the flow meter and the regulating valve Then import four sets of static mixer groups to mix to obtain a mixed solution;

[0042] (3) Due to the polycondensation process in the previous production process of TMQ, the concentration of hydrochloric acid in the polycondensation reaction solution is too high. After the mixed solution comes out of the static mixer, the online pH meter shows pH = 6, and the DCS automatically adjusts the parameters th...

Embodiment 3

[0044] (1) In the production process of anti-aging agent TMQ such as "two-step method" or "one-step method", aniline and acetone are condensed and polymerized under acidic conditions to obtain the polycondensation reaction solution of TMQ, which is placed in a storage tank for buffer storage;

[0045] (2) Using the distributed control system (DCS system) according to pH=8, control the flow meter and the regulating valve to initially mix the TMQ polycondensation reaction solution and the liquid caustic soda (sodium bicarbonate solution) and then import it into four sets of static mixers for mixing , to obtain a mixed solution;

[0046] (3) Due to the polycondensation process in the previous production process of TMQ, the concentration of hydrochloric acid in the polycondensation reaction solution is too low. After the mixed solution comes out of the static mixer, the online pH meter shows pH = 12, and the DCS automatically adjusts the parameters through the set ratio to reduce ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com