Biogas digester

The technology of a biogas digester and a gas storage chamber is applied in the field of biogas digesters, which can solve the problems of low gas production rate, low utilization rate of fermentation raw materials, influence on the gas production volume of the digester, etc., and achieve the effect of increasing the gas production volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

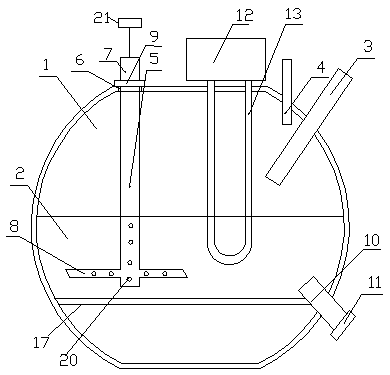

[0025] See figure 1 , A biogas digester, comprising a gas storage chamber 1 and a fermentation chamber 2, a feed pipe 3 and a gas outlet pipe 4 communicating with the gas storage chamber 1, and also includes a stirrer 5. The outer wall of the gas storage chamber 1 is provided with an annular hole 6 for stirring The stirring shaft 7 of the device 5 extends into the fermentation chamber 2 through the annular hole 6, a stirring blade 8 located in the fermentation chamber 2 is provided on the stirring shaft 7, and a stirring shaft 7 located outside the gas storage chamber 1 A card cover 9 is sleeved, the diameter of the card cover 9 is not less than the inner diameter of the annular hole 6, a discharging tube 10 is arranged in the fermentation chamber 2, and a discharging cover 11 is arranged at the outlet of the discharging tube 10, the A solar heat collector 12 is fixedly connected to the top of the gas storage chamber 1, and a heat collection return pipe 13 is connected to the so...

Embodiment 2

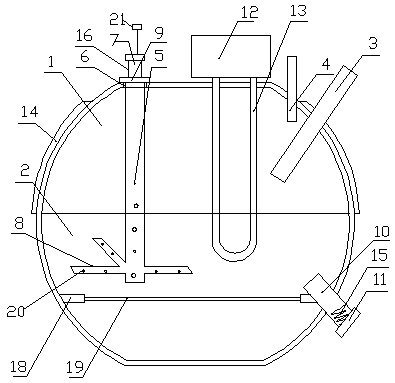

[0028] See figure 2 , A biogas digester, comprising a gas storage chamber 1 and a fermentation chamber 2, a feed pipe 3 and a gas outlet pipe 4 communicating with the gas storage chamber 1, and also includes a stirrer 5. The outer wall of the gas storage chamber 1 is provided with an annular hole 6 for stirring The stirring shaft 7 of the device 5 extends into the fermentation chamber 2 through the annular hole 6, a stirring blade 8 located in the fermentation chamber 2 is provided on the stirring shaft 7, and a stirring shaft 7 located outside the gas storage chamber 1 A card cover 9 is sleeved, the diameter of the card cover 9 is not less than the inner diameter of the annular hole 6, a discharging tube 10 is arranged in the fermentation chamber 2, and a discharging cover 11 is arranged at the outlet of the discharging tube 10, the A solar heat collector 12 is fixedly connected to the top of the gas storage chamber 1, and a heat collection return pipe 13 is connected to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com