Wood turf composite particle, preparation method for same and application to cigarettes

A technology of carbon compounding and herbal medicine, which is applied in the fields of application, tobacco, smoke oil filter elements, etc., can solve the problem of no promotion of the adsorption of harmful substances, achieve richness and fineness, good development and application prospects, and easy industrial production Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

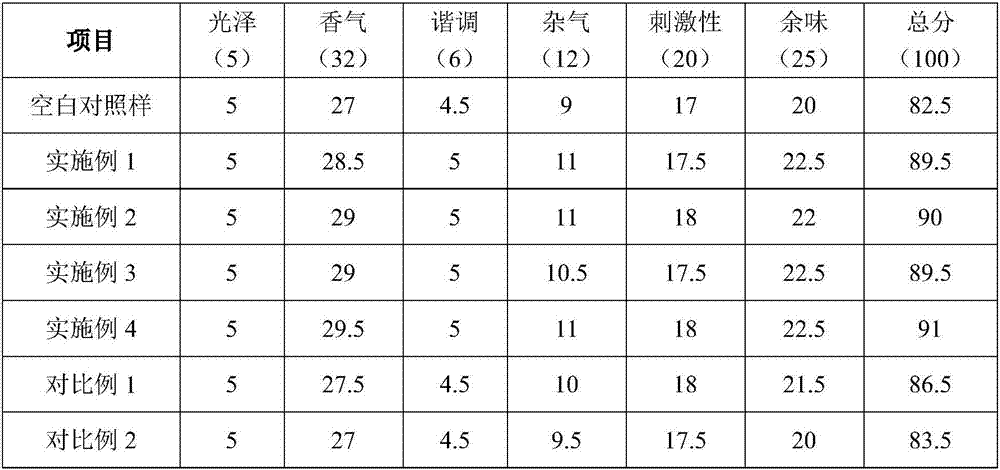

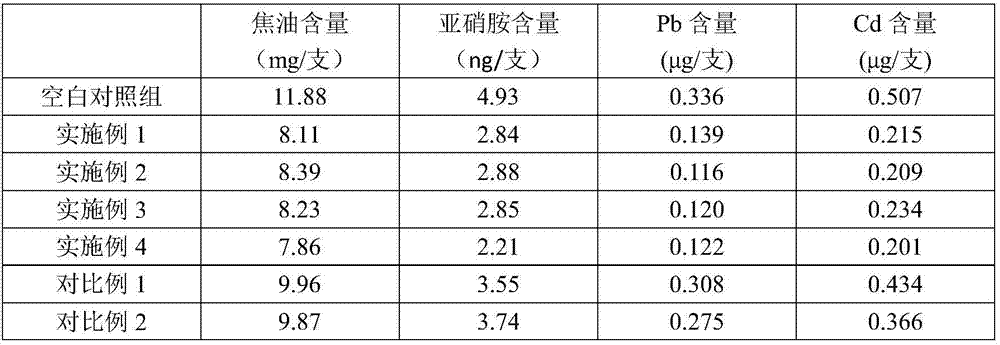

Examples

Embodiment 1

[0026] A herbal charcoal composite particle, including herbal charcoal, tobacco extract, binder and adsorption promoter, each component by weight: 10 parts of herbal charcoal, 1 part of tobacco extract, 2 parts of binder, and adsorption Accelerator 0.8 parts. The herbal charcoal is formed by charcoal processing of hawthorn, the adsorption accelerator is a compound extract of saponins and capillary grass, and the binder is dextrin pulp.

[0027] Among them, the carbonization process of the herbal charcoal is as follows: dry fresh hawthorn at 100°C for 2 hours, then heat to 200°C for pre-carbonization, the pre-carbonization time is 1 hour, after the pre-carbonization is completed, then raise the temperature to 300°C Carbonize for 1 hour. After the carbonization is completed, air-cool to room temperature, then pulverize the carbonized product and pass through a 50-mesh sieve. The collected sieve is the herbal charcoal.

[0028] The preparation process of the tobacco extract is ...

Embodiment 2

[0039] A herbal charcoal composite particle, comprising herbal charcoal, tobacco extract, binder and adsorption promoter, each component by weight: 10 parts of herbal charcoal, 2 parts of tobacco extract, 4 parts of binder, and adsorption Accelerator 2 parts. The herbal charcoal is formed by carbonizing rhubarb, the adsorption accelerator is a composite extract of saponins and capillary grass, and the binder is dextrin pulp.

[0040] Among them, the carbonization process of the herbal charcoal is as follows: fresh rhubarb is dried at 120°C for 3 hours, then heated to 200°C for pre-carbonization, and the pre-carbonization time is 1 hour. After the pre-carbonization is completed, the temperature is raised to 320°C. Carbonize for 1 hour. After the carbonization is completed, air-cool to room temperature, then pulverize the carbonized product and pass through a 100-mesh sieve. The collected sieve is the herbal charcoal.

[0041] The preparation process of the tobacco extract is as...

Embodiment 3

[0052] A herbal charcoal composite particle, including herbal charcoal, tobacco extract, binder and adsorption promoter, each component by weight: 10 parts of herbal charcoal, 3 parts of tobacco extract, 4 parts of binder, and adsorption Accelerator 4 parts. The herbal charcoal is formed by making Scutellaria baicalensis through charcoal, the adsorption accelerator is a composite extract of saponins and capillary grass, and the binder is dextrin pulp.

[0053] Among them, the carbonization process of the herbal charcoal is as follows: dry Scutellaria baicalensis at 150°C for 3 hours, then heat it to 220°C for pre-carbonization, the pre-carbonization time is 2 hours, after the pre-carbonization is completed, then raise the temperature to 350°C for carbonization After 1.5h, air-cool to room temperature after the carbonization is completed, then pulverize the carbonized product and pass through a 20-mesh sieve. The collected sieve is the herbal charcoal.

[0054] The preparatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com