Efficient dewatering device for natural gas

A dehydration device, natural gas technology, applied in the direction of combined devices, gas fuel, petroleum industry, etc., can solve the problems of low dehydration efficiency, low efficiency, and various equipment in the dehydration tower, so as to improve efficiency and quality, save time, and improve production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

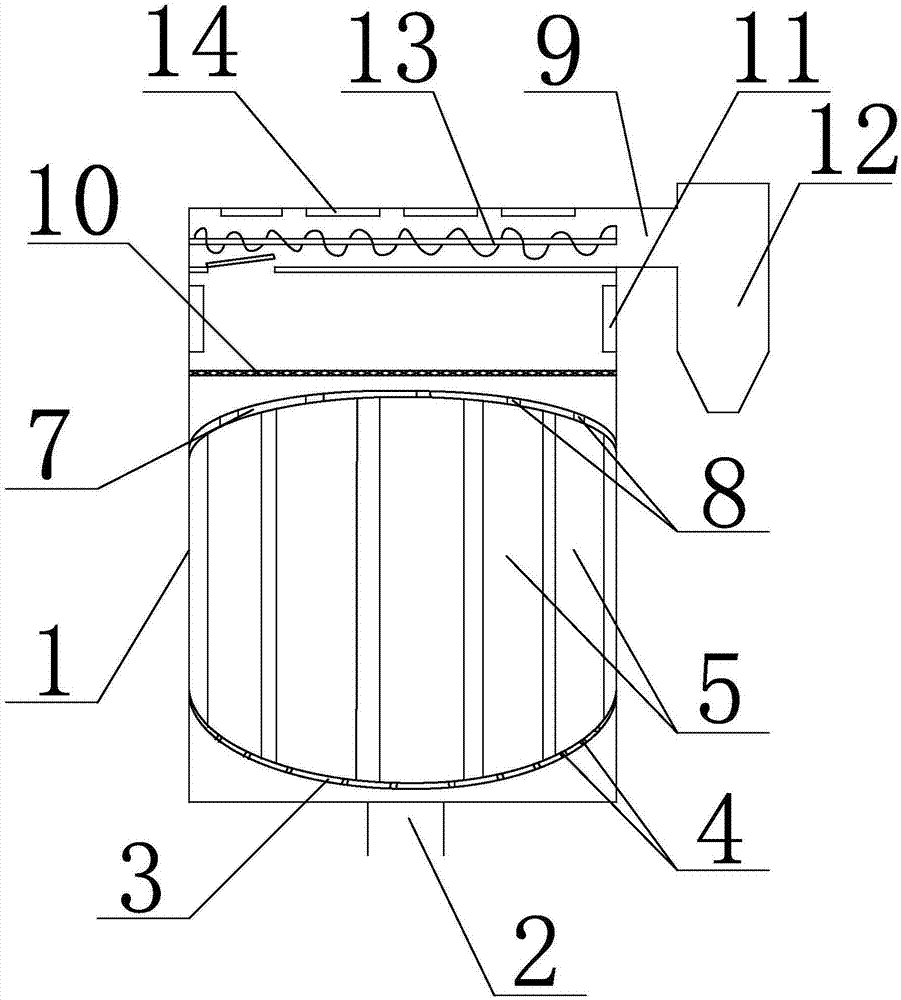

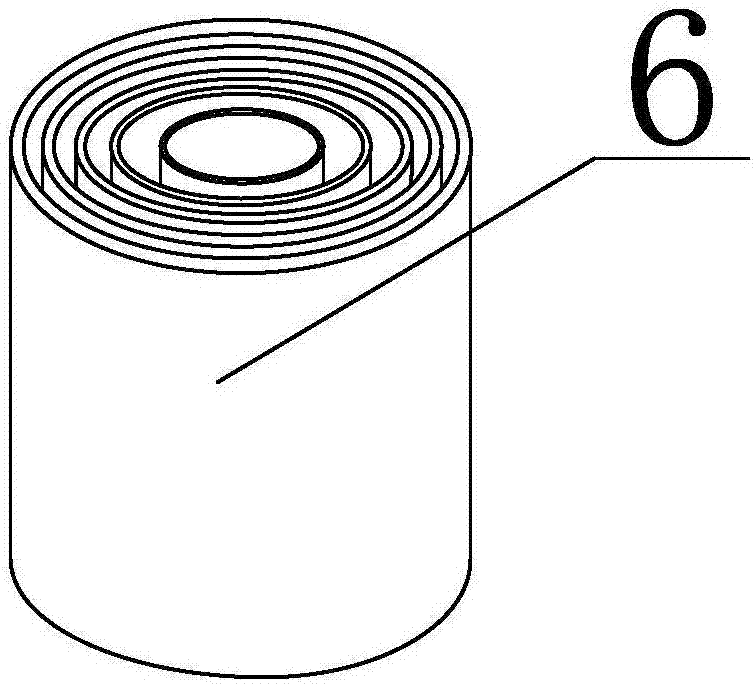

[0022] Such as figure 1 with figure 2 As shown, the high-efficiency dehydration device for natural gas of the present invention includes a dehydration tower 1, a natural gas inlet 2 is provided at the bottom of the dehydration tower 1, a spherical arc plate 3 is provided above the air inlet 2 in the dehydration tower 1, and the spherical arc The edge of the plate 3 is fully attached to the inner wall of the dehydration tower 1 and the opening faces upwards. The spherical arc plate 3 is evenly provided with a plurality of ventilation holes 4, and the spherical arc plate 3 is connected with a plurality of dehydration pipes 5. The ventilation holes 4 and the dehydration pipes The lower end of 5 is connected, and the dehydration pipe 5 is provided with a shunt sleeve 6. The shunt sleeve 6 is formed by multiple sleeves with different sizes from the inside to the outside. The shunt sleeve 6 can rotate around its own axis. , and the sleeves are all mesh-like hollow structures, fill...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com