Preparation method of novel and green mono-dispersive silicon dioxide nanospheres

A technology of silica and nanospheres, applied in the field of nanomaterials, can solve the problems of difficulty in obtaining high-quality SiO2 nanospheres, poor controllability and repeatability of silica nanospheres, and restrictions on popularization and application, and achieve uniform appearance , the system can be reused, and the follow-up processing is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

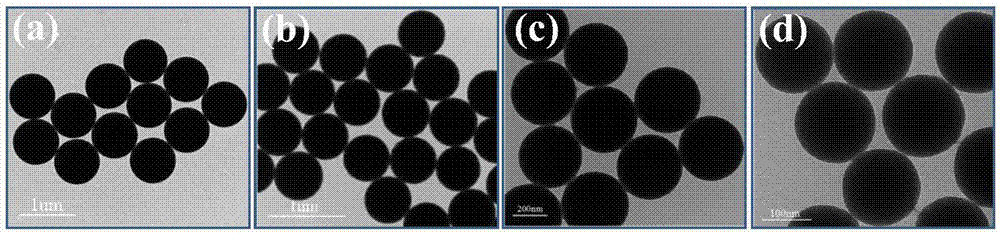

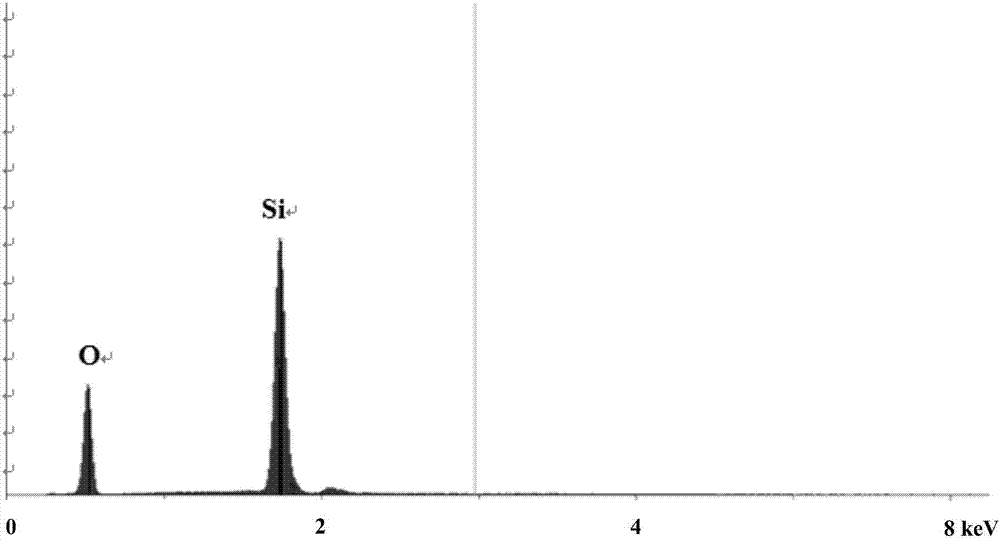

Embodiment 1

[0042] (1) Mix 4 g of secondary ultrapure water with 76 g of ethanol, add 20 g of dichloromethane under stirring conditions, and continue stirring for 10 min after the addition is complete.

[0043] (2) Slowly add 1.3ml tetraethyl orthosilicate into the O / W type surfactant-free microemulsion system obtained in step (1) under stirring. After the addition is completed, sonicate for 10 minutes and stir for 20 minutes.

[0044] (3) Move the O / W type surfactant-free microemulsion system containing tetraethyl orthosilicate obtained in step (2) into an ice-water bath, and slowly add 3ml of ammonia water (25wt%) into it under stirring conditions, and continue stirring for 10min Afterwards, the reaction device was moved into a water bath at 25° C. for 24 hours of static reaction.

[0045] (4) After the reaction is over, a white solid is obtained by centrifugation, and the white solid is washed 3 times to obtain SiO 2 nanospheres. The remaining liquid components were distilled to coll...

Embodiment 2

[0047] (1) Mix 4 g of secondary ultrapure water with 36 g of ethanol, add 10 g of dichloromethane under stirring conditions, and continue stirring for 10 min after the addition is complete.

[0048] (2) Slowly add 1.3ml tetraethyl orthosilicate into the O / W type surfactant-free microemulsion system obtained in step (1) under stirring. After the addition is completed, sonicate for 10 minutes and stir for 20 minutes.

[0049] (3) Move the O / W type surfactant-free microemulsion system containing tetraethyl orthosilicate obtained in step (2) into an ice-water bath, and slowly add 3ml of ammonia water (25wt%) into it under stirring conditions, and continue stirring for 10min Afterwards, the reaction device was moved into a water bath at 25° C. for 24 hours of static reaction.

[0050] (4) After the reaction is over, a white solid is obtained by centrifugation, and the white solid is washed 3 times to obtain SiO 2 nanospheres. The remaining liquid components were distilled to coll...

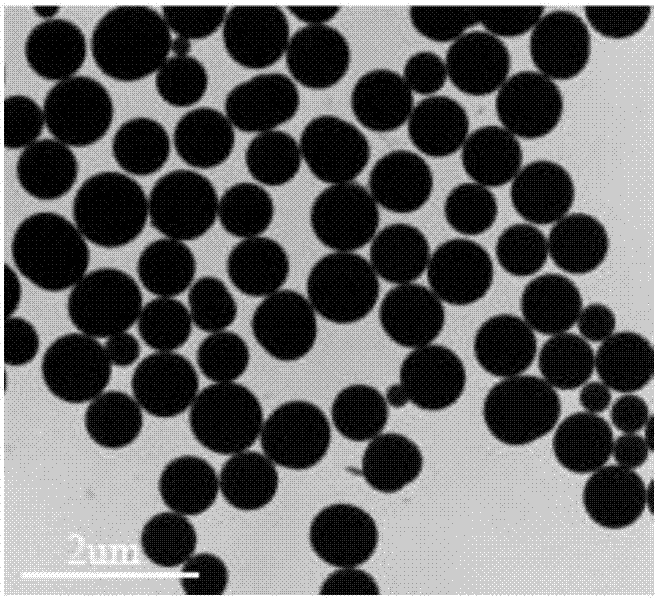

Embodiment 3

[0052] (1) Mix 4 g of secondary ultrapure water with 16 g of ethanol, add 5 g of dichloromethane under stirring conditions, and continue stirring for 10 min after the addition is complete.

[0053] (2) Slowly add 1.3ml tetraethyl orthosilicate into the O / W type surfactant-free microemulsion system obtained in step (1) under stirring. After the addition is completed, sonicate for 10 minutes and stir for 20 minutes.

[0054] (3) Move the O / W type surfactant-free microemulsion system containing tetraethyl orthosilicate obtained in step (2) into an ice-water bath, and slowly add 3ml of ammonia water (25wt%) into it under stirring conditions, and continue stirring for 10min Afterwards, the reaction device was moved into a water bath at 25° C. for 24 hours of static reaction.

[0055] (4) After the reaction is over, a white solid is obtained by centrifugation, and the white solid is washed 3 times to obtain SiO 2 nanospheres. The remaining liquid components were distilled to colle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com