Novel method for refining dronedarone hydrochloride

A technology of dronedarone hydrochloride and dronedarone, which is applied in the direction of organic chemistry, can solve the problems of large solvent usage, high economic cost and environmental pressure, troublesome operation, etc., achieve mild reaction conditions and avoid debutylation Degradation of impurities and high refining efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

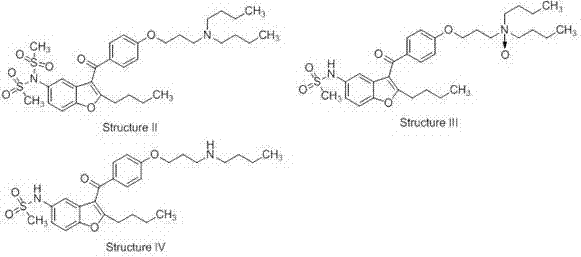

Image

Examples

Embodiment 1

[0014] The crude dronedarone hydrochloride (10.00 g) was added to ethyl acetate (50.0 mL), and 1% NaOH aqueous solution (70.0 mL) was slowly added, and stirred until it was completely dissolved. After standing for liquid separation, the organic phase was extracted with ethyl acetate (10.0 mL), and then the organic phases were combined and washed with 10% brine (60.0 mL) once. Add anhydrous sodium sulfate (2.00g) for drying treatment and suction filtration. Under the condition of -10~0℃, slowly add 20% hydrogen chloride ether solution (3.5mL) dropwise to the ethyl acetate solution. After a large amount of solids gradually precipitate in the system, continue to heat and stir for 2 hours. After suction filtration, the filter cake was rinsed with ethyl acetate (10.0 mL) and dried under vacuum at 50°C to obtain a refined dronedarone hydrochloride product (8.61 g) with a yield of 86%. The product liquid phase purity and main impurity content are shown in Table 1.

Embodiment 2

[0016] The crude dronedarone hydrochloride (10.00g) was added to 2-methyltetrahydrofuran (50.0mL), and 1% NaOH aqueous solution (70.0mL) was slowly added, and stirred until the dissolution was complete. After standing for liquid separation, the organic phase was extracted with 2-methyltetrahydrofuran (10.0 mL), and then the organic phases were combined and washed with 10% brine (60.0 mL) once. Add anhydrous sodium sulfate (2.00g) for drying treatment and suction filtration. Under the condition of 0~10℃, slowly add a 20% hydrogen chloride isopropanol solution (3.5mL) dropwise to the 2-methyltetrahydrofuran solution. After a large amount of solids gradually precipitate in the system, continue to heat and stir for 2 hours. After suction filtration, the filter cake was rinsed with 2-methyltetrahydrofuran (10.0 mL) and dried under vacuum at 50°C to obtain a refined dronedarone hydrochloride product (9.00 g) with a yield of 90%. The product liquid phase purity and main impurity cont...

Embodiment 3

[0018] The crude dronedarone hydrochloride (10.00 g) was added to ethyl acetate (50.0 mL), 1% KOH aqueous solution (100.0 mL) was slowly added, and the solution was stirred until it was completely dissolved. After standing for liquid separation, the organic phase was extracted with ethyl acetate (10.0 mL), and then the organic phases were combined and washed with 10% brine (60.0 mL) once. Add anhydrous sodium sulfate (2.00g) for drying treatment and suction filtration. Under the condition of 20~30℃, slowly dropwise add 20% hydrogen chloride ethyl acetate solution (3.5mL) to the ethyl acetate solution. After a large amount of solids gradually precipitate in the system, continue to keep the temperature and stir for 2 hours. After suction filtration, the filter cake was rinsed with ethyl acetate (10.0 mL) and dried under vacuum at 50°C to obtain a refined dronedarone hydrochloride product (8.10 g) with a yield of 81%. The product liquid phase purity and main impurity content are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com