Novel heat insulation coating

A new type of thermal insulation coating and raw material technology, applied in the field of architectural decoration, can solve the problems of poor heat insulation and flame retardancy, achieve good weather resistance, improve heat resistance, and slow down the effect of heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

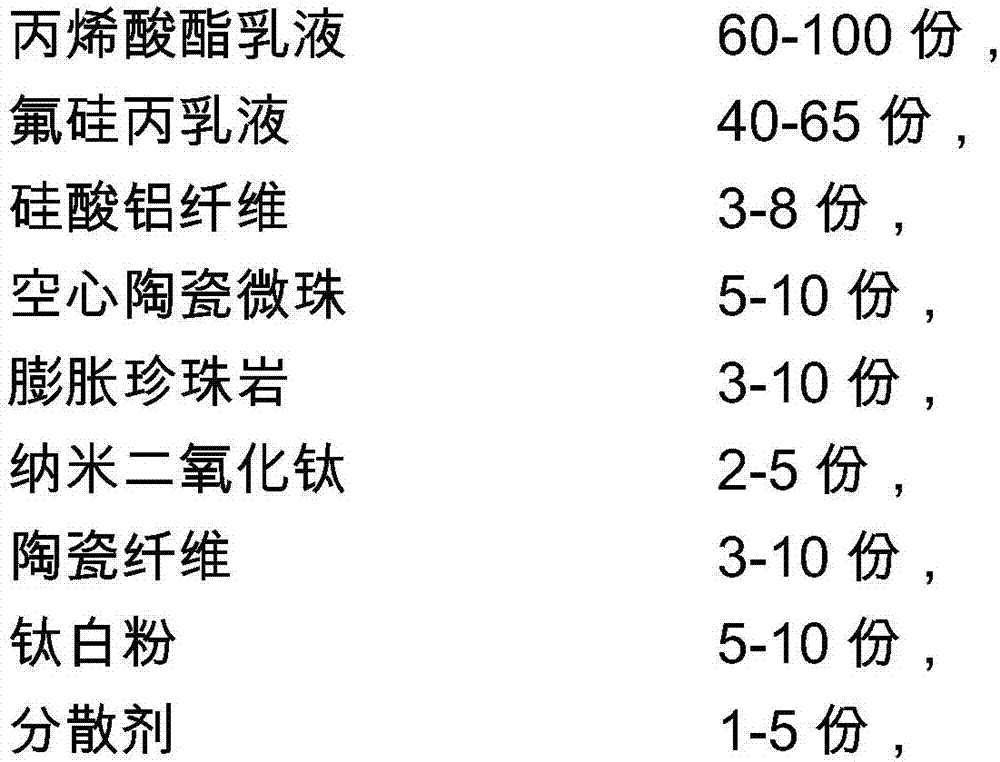

[0016] This embodiment discloses a new type of thermal insulation coating, including the following raw materials measured in parts by mass:

[0017]

Embodiment 2

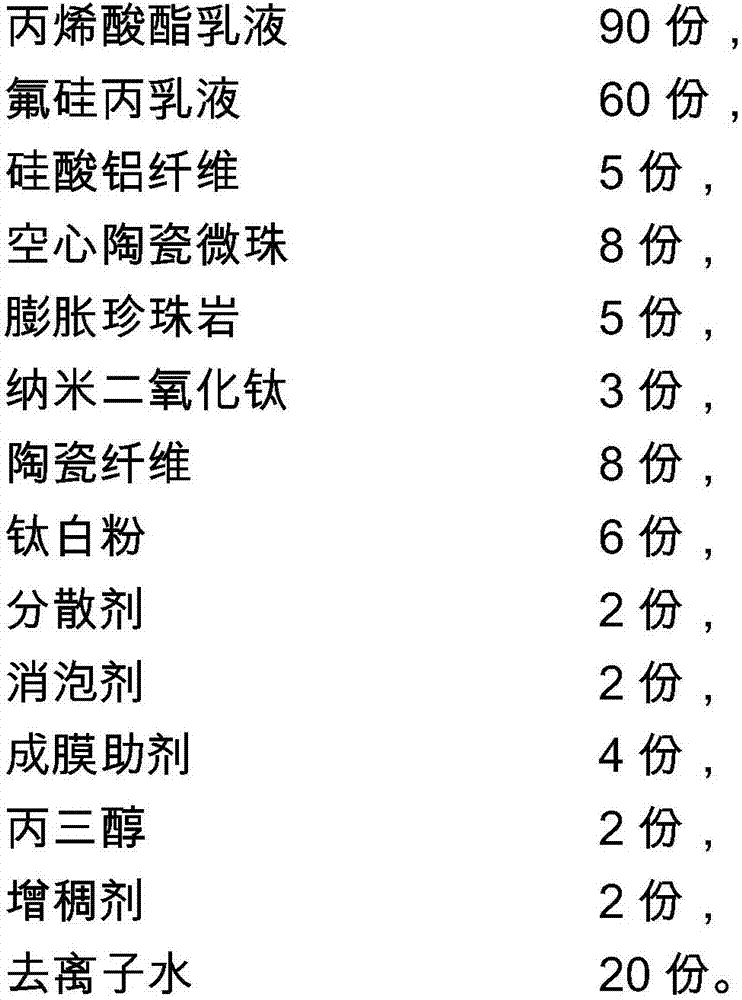

[0019] This embodiment discloses a new type of thermal insulation coating, including the following raw materials measured in parts by mass:

[0020]

Embodiment 3

[0022] This embodiment discloses a new type of thermal insulation coating, including the following raw materials measured in parts by mass:

[0023]

[0024]

[0025] Wherein, the particle size of the hollow ceramic microbeads is 30-100 μm. The defoamer is polyether modified silicone. The dispersant is sodium hexametaphosphate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Initial viscosity | aaaaa | aaaaa |

| Microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com