Preparation method and application of monodisperse polymer fluorescent microsphere

A technology of fluorescent microspheres and polymers, applied in chemical instruments and methods, luminescent materials, etc., can solve the problems of cumbersome preparation methods and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] (1) Preparation of the oil phase mixture: adding functional reactive monomers, fluorescent molecules, and reactive monomer styrene into the superhydrophobic agent n-hexadecane, and ultrasonically mixing to form an oil phase mixture;

[0039] (2) Preparation of the aqueous phase mixture: take a certain amount of surfactant and disperse it in water, with a total volume of 9 mL, and ultrasonically treat it to completely dissolve it, forming an aqueous phase mixture;

[0040] (3) Preparation of initiator aqueous solution: add initiator to 1mL water, shake to dissolve;

[0041] (4) Emulsification process: add the water phase to the oil phase, stir and ultrasonically carry out pre-emulsification, and then process it with a cell pulverizer under a certain power and ice bath conditions for 10 minutes until complete emulsification;

[0042] (5) Transfer the above-mentioned emulsion to a 100mL three-necked flask, add the aqueous initiator solution prepared in (3), stir and mix we...

Embodiment 1

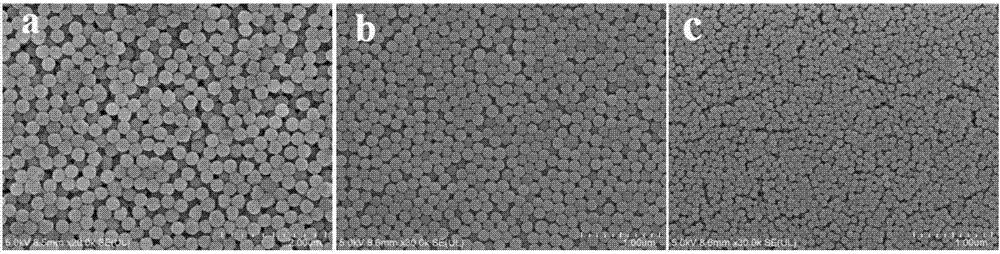

[0054] Effect of Surfactant Addition on the Particle Size and Dispersion of Polymer Microspheres

[0055] (1) Preparation of the oil phase mixture: Weigh 1.8 g of styrene and 0.2 g of acrylic acid and add it to 0.1 g of superhydrophobic agent n-hexadecane, and ultrasonically mix evenly to form an oil phase mixture;

[0056] (2) Preparation of aqueous phase mixture: the surfactant sodium dodecyl sulfate (SDS) of 0.002g (0.1wt%) or 0.01g (0.5wt%) or 0.02g (1wt%) is dispersed in water respectively, The total volume is 9mL, shake to dissolve completely, and it is an aqueous phase mixture;

[0057] (3) Preparation of initiator aqueous solution: Weigh 0.02g of potassium persulfate into 1mL of water, shake to dissolve;

[0058] (4) Emulsification: add the water phase to the oil phase, stir or ultrasonically carry out pre-emulsification, and then process it with a cell pulverizer for 10 minutes under the condition of 250W power and ice bath until complete emulsification;

[0059] (5...

Embodiment 2

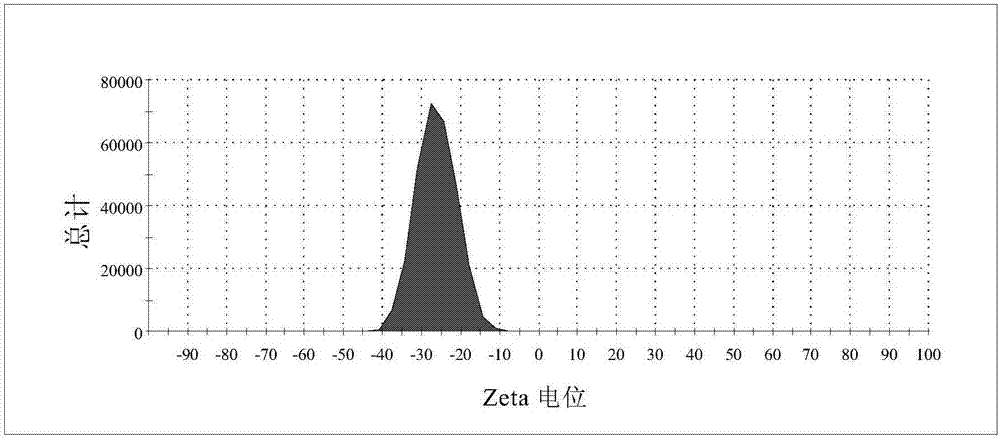

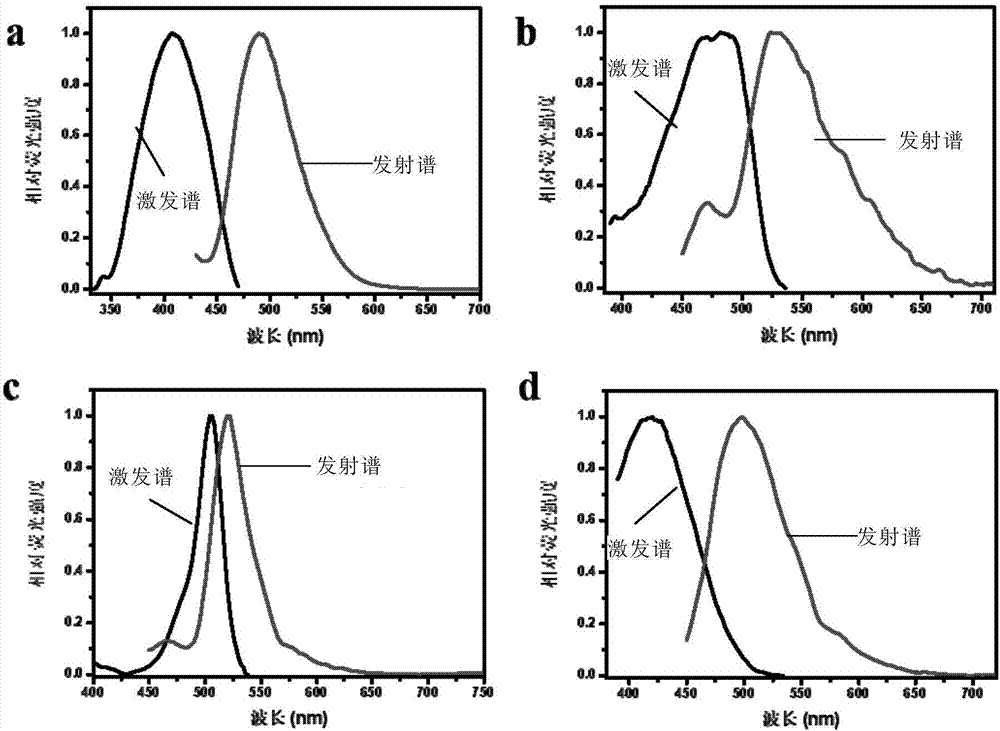

[0062] The preparation of the polymer fluorescent microspheres of carboxyl functionalization comprises the following steps:

[0063] (1) Preparation of oil phase mixture: Weigh 1.8g of styrene, 0.2g of acrylic acid and 0.01g (0.5wt%) of naphthalimide fluorescent molecules into 0.1g of superhydrophobic agent n-hexadecane, and ultrasonically mix Uniform, oil phase mixture;

[0064] (2) Preparation of the aqueous phase mixture: take 0.005 g of surfactant sodium lauryl sulfate and disperse it in water with a total volume of 9 mL, shake it to dissolve completely, and form an aqueous phase mixture;

[0065] (3) Preparation of initiator aqueous solution: Weigh 0.02g of potassium persulfate into 1mL of water, shake to dissolve;

[0066] (4) Emulsification process: add the water phase to the oil phase, stir or ultrasonically carry out pre-emulsification, and then process it with a cell pulverizer for 10 minutes under the condition of 250W power and ice bath until complete emulsificati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com