A stone-plastic floor with good dimensional stability

A technology for dimensional stability and stone-plastic flooring, applied to paper/cardboard layered products, wood layered products, floors, etc., can solve the problems of easy cracking and non-environmental protection of composite floors, so as to avoid local heat accumulation and save energy Cost, the effect of reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

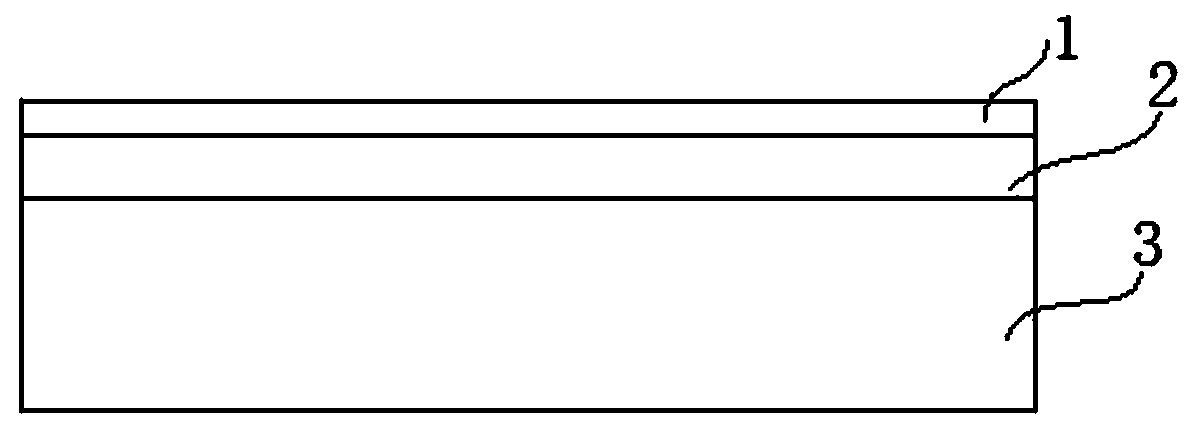

[0040] combine figure 1 , the stone-plastic floor with good dimensional stability in this embodiment includes a surface plate 1, a buffer layer 2 and a base plate 3, the surface plate 1 and the base plate 3 are connected by a buffer layer 2, and the buffer layer 2 is a technical wood layer, a non-woven One of the fabric layer and the glass fiber layer or a combination of two or a combination of the three. Specifically, in this embodiment, the buffer layer 2 is only a technical wood layer, and the thickness of the technical wood layer is 0.3-0.4 mm. The substrate 3 is a PVC stone-plastic board. The surface board 1 includes wood grain paper, the surface of the wood grain paper is covered with a wear-resistant and fireproof layer, and the wood grain paper and the wear-resistant fireproof layer together form the surface board 1 . Specifically in this embodiment, the wear-resistant and fire-resistant layer is an aluminum oxide layer.

[0041] Most of the composite floors in the p...

Embodiment 2

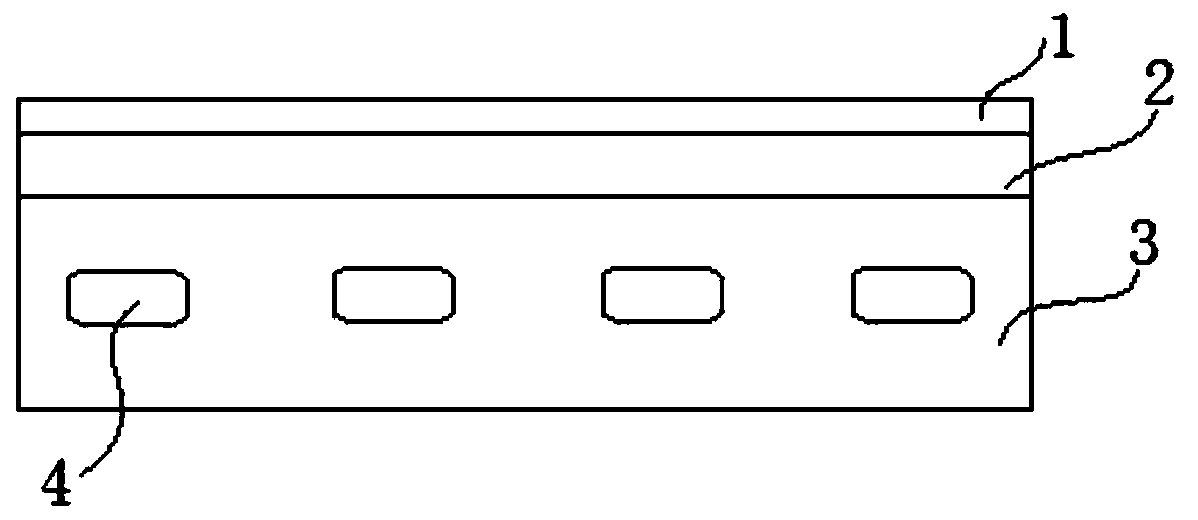

[0050] combine figure 2 , the good stone-plastic floor of dimensional stability of the present embodiment, its structure is basically the same as embodiment 1, and its difference is: in the concrete present embodiment, the thickness of technical wood layer is 0.4mm;

[0051] In the stone-plastic floor with good dimensional stability in this embodiment, the inside of the substrate 3 is provided with a through hole 4 along the length direction. There are multiple through holes 4, and the plurality of through holes 4 are arranged in parallel along the width direction of the substrate 3; It can effectively reduce the weight of the substrate 3, save the production cost, and play a buffer role when the substrate 3 is deformed due to uneven heating, and can absorb most of the deformation on the substrate 3, eliminate the internal stress on the substrate 3, and prolong the life of the substrate 3. Its service life effectively avoids the occurrence of floor deformation. It should be ...

Embodiment 3

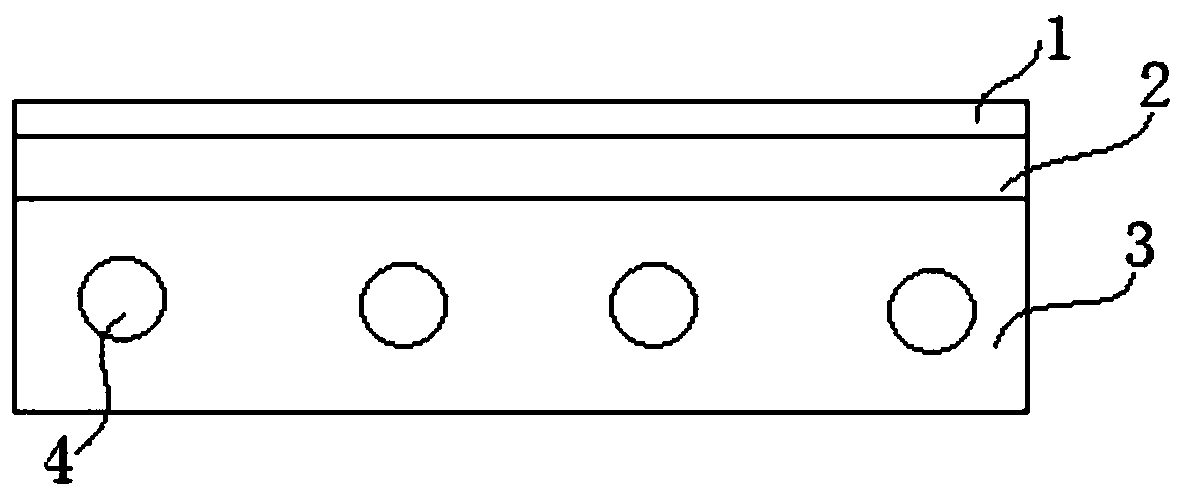

[0053] combine image 3 , the stone-plastic floor with good dimensional stability in this embodiment has basically the same structure as in Embodiment 2, the difference is that the cross section of the through hole 4 in this embodiment is circular, and the through hole with a circular cross section 4 can maximize the contact area between the air and the inner wall of the through hole 4 , enhance the effect of convective heat transfer in the through hole 4 , and is more conducive to avoiding local thermal deformation of the substrate 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com