Passive-type double-flow-passage solar water boiler

A technology of solar boiling water and dual flow paths, applied in solar collectors, solar collectors using working fluids, solar heat storage, etc., can solve the problem that pure water cannot reach the temperature of boiling water, and can only reach 60 or 70 degrees. Poor tap water quality and other problems, to achieve the effect of compact structure, high heat storage density, and no power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

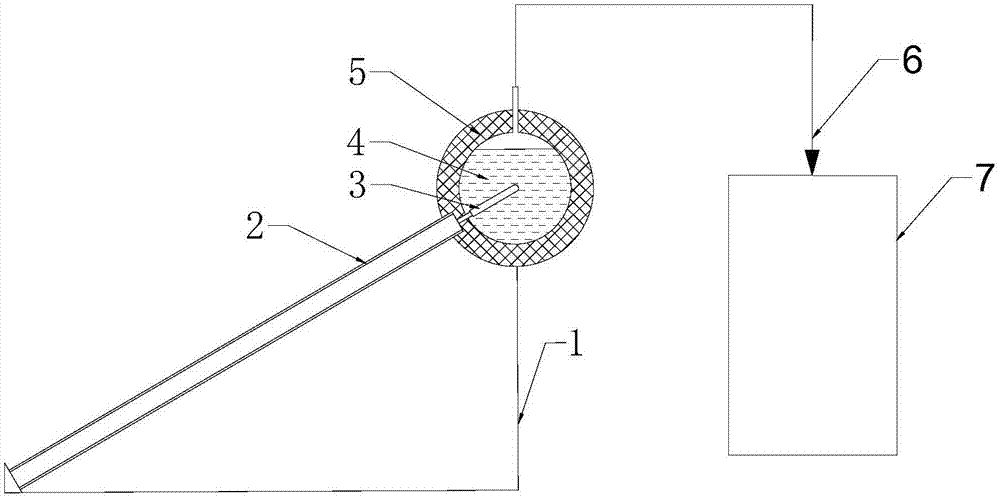

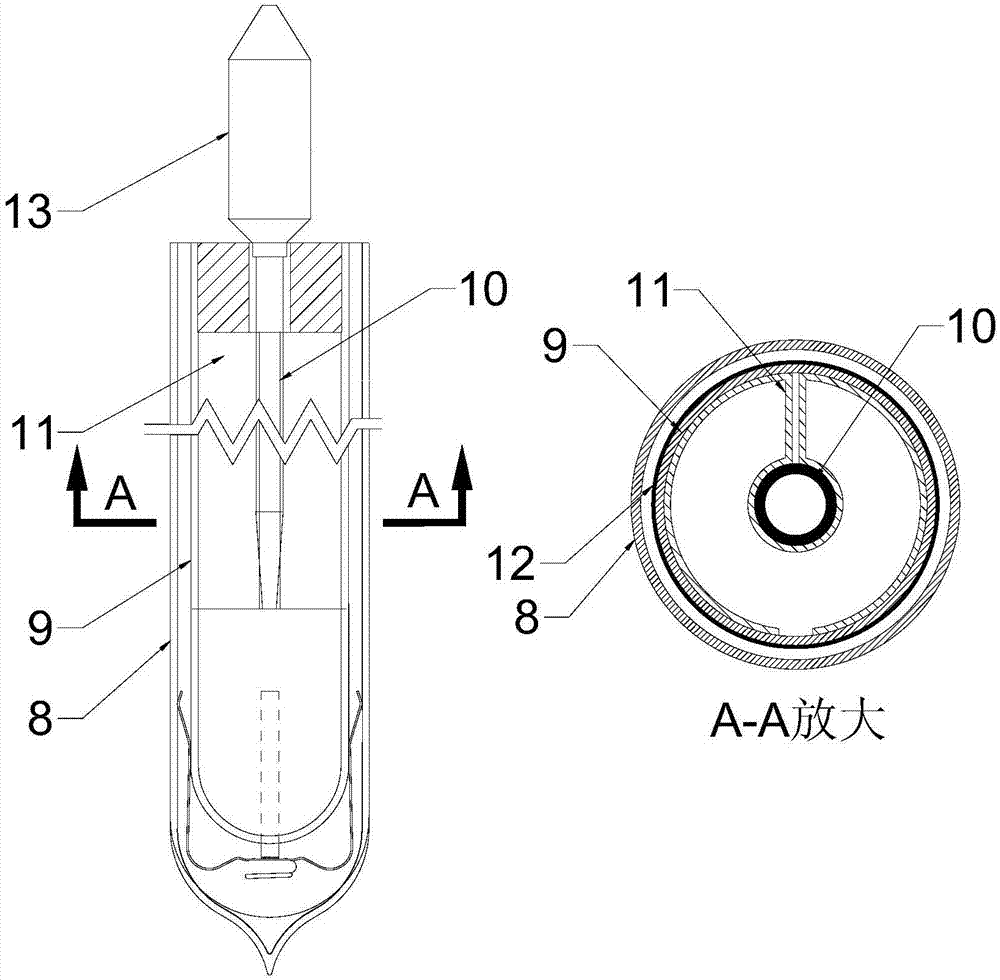

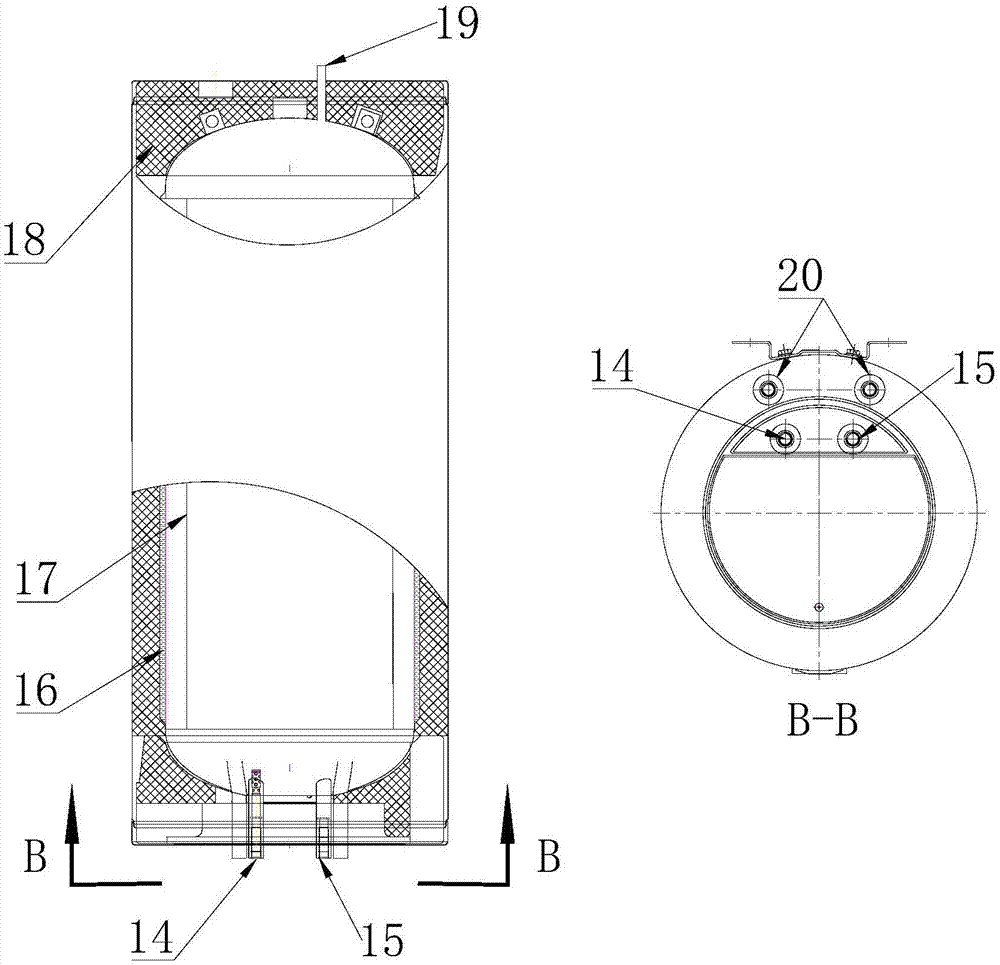

[0031]In this embodiment, the heat pipe type solar heat collecting tube is placed at an angle of 30° to the ground. The heat collecting unit contains two steam drum groups, each steam drum has a diameter of 130 mm and a length of 2000 mm, and each steam drum group contains 24 commercial metal heat pipe type full vacuum glass heat collecting tubes, wherein the full vacuum glass heat collecting tubes The outer diameter is 58mm, the inner diameter is 47mm, and the effective length is 1600mm; the outer diameter of the metal heat pipe condensing end installed in the glass heat collecting tube is 28mm, and the length is 120mm; the volume of the boiling water tank is 120L, the height is 1200mm, the outer diameter of the jacket is 392mm, and the inner diameter is 370mm The sleeve regenerator is composed of two sleeves, both of which are 1000mm high, of which the inner sleeve has an inner diameter of 156mm and an outer diameter of 206mm, and the outer sleeve has an inner diameter of 260...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com