Method for shortening tobacco leaf baking time of closed barking room

A kind of baking time and airtight technology, which is applied in the direction of tobacco, tobacco preparation, application, etc., can solve the problem of low air content, etc., and achieve the effects of reducing energy consumption, shortening time, and promoting maturation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

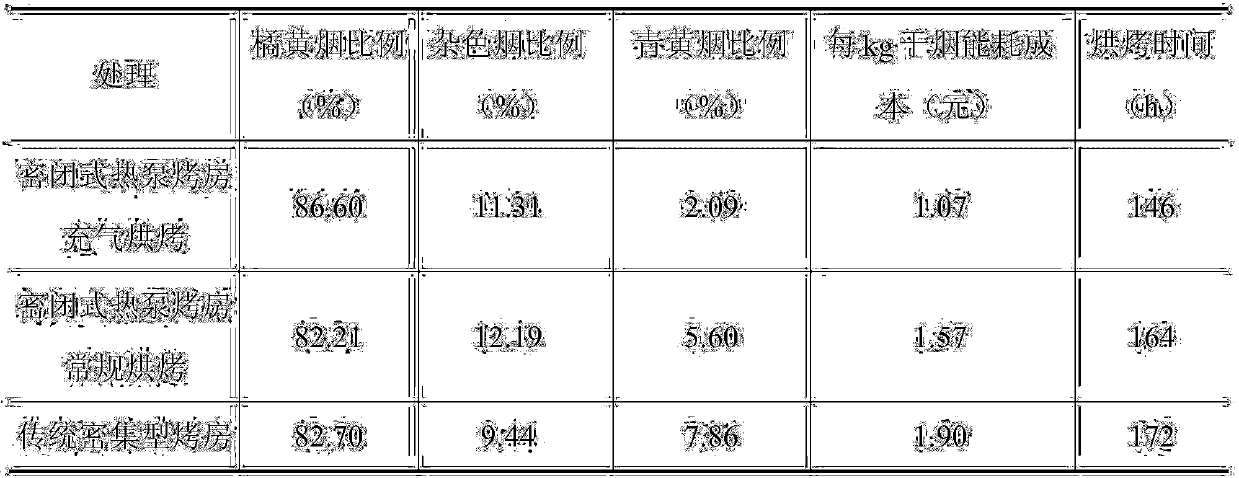

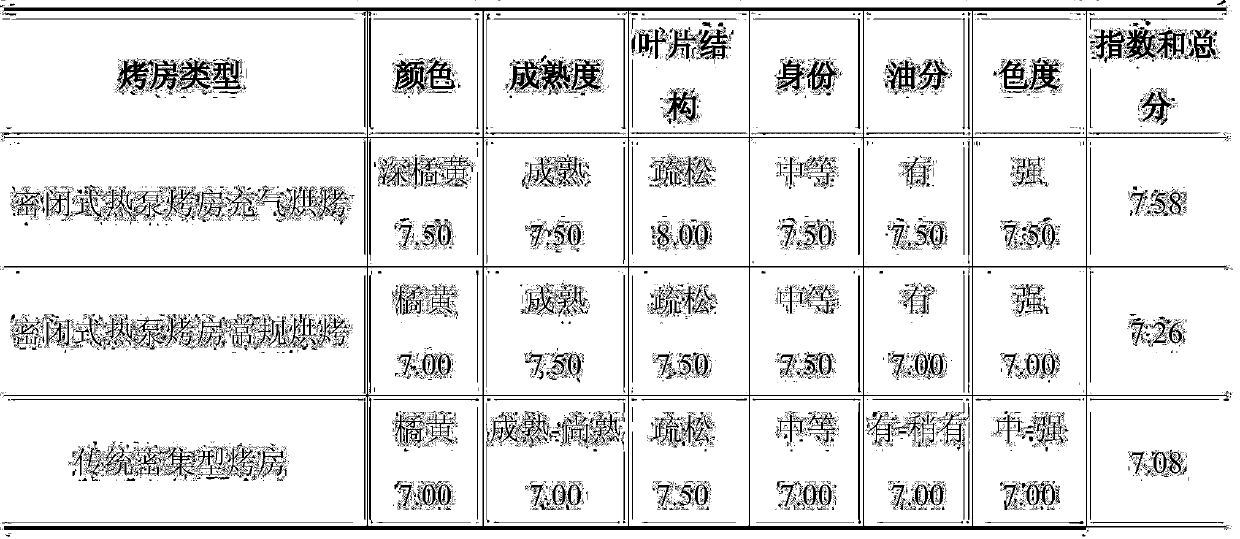

Embodiment 1

[0024] A method for shortening the curing time of tobacco leaves in an airtight curing room. The upper leaves (4-6 leaves in the upper part) of K326 are used as the test materials, the sundries are removed, cigarettes are classified into cigarettes, and cigarettes are loaded, and the tobacco leaves with the same maturity are placed in the same Baking in the oven. The airtight heat pump barn is provided by Yunnan Zhonghai Luther Clean Technology Co., Ltd. The airtight heat pump barn has no moisture and heat exhaust ports, and the excess water is removed by the equipment in the form of condensed water. The size of the smoke chamber is 8.0m×2.7m× 3.5m, 2 roads and 3 floors. In the early stage of yellowing for 0-12 hours, fill with 1.2% oxygen, in the middle and late stages of yellowing (i.e. start baking for 13-85 hours, preferably start baking for 45-72 hours), fill in 1.5% carbon dioxide, and in the later stage of color fixing to dry tendons 0.5% carbon dioxide is charged duri...

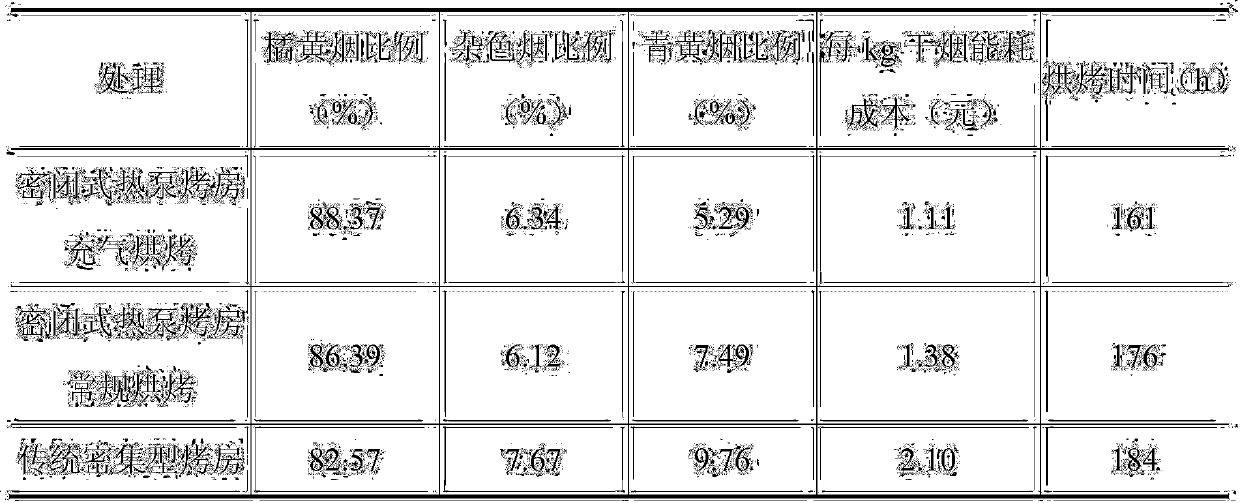

Embodiment 2

[0036] The upper leaves of Yunyan 87 (4-6 leaves in the upper part) were used as the test materials, the sundries were removed, the tobacco was classified into cigarettes, and the tobacco leaves with the same maturity were placed in the same roasting room for curing. The airtight heat pump barn is provided by Yunnan Zhonghai Lude Clean Technology Co., Ltd. The specifications of the barn are 8.0m×2.7m×3.5m, with 2 channels and 3 floors. In the early stage of yellowing for 0-12 hours, fill with 1.0% oxygen, in the middle and late stages of yellowing (that is, start baking for 13-85 hours, preferably start baking for 45-72 hours), fill in 1.2% carbon dioxide, and in the later stage of color fixing to dry tendons 0.5% carbon dioxide is charged during the period (ie, 86-176 hours after the start of baking, preferably 96-116 hours after the start of baking). Compared with the traditional dense curing room tobacco curing and the existing closed heat pump curing technology.

[0037] ...

Embodiment 3

[0049]The middle leaves of K326 (the 10th to 12th tobacco leaves in the middle) were used as the test material, the sundries were removed, the tobacco was classified into cigarettes, and the tobacco leaves with the same maturity were placed in the same roasting room for curing. The airtight heat pump barn is provided by Yunnan Zhonghai Lude Clean Technology Co., Ltd. The specifications of the barn are 8.0m×2.7m×3.5m, with 2 channels and 3 floors. In the early stage of yellowing for 0-12 hours, fill in 0.8% carbon dioxide, in the middle and late stage of yellowing (i.e. start baking for 13-85 hours, preferably start baking for 45-72 hours), fill in 1.0% carbon dioxide, and in the later stage of color fixing to dry gluten 0.3% carbon dioxide is charged during the period (ie, 86-176 hours after the start of baking, preferably 96-116 hours after the start of baking). Compared with the traditional dense curing room tobacco curing and the existing closed heat pump curing technology....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com