Preparation and application of powder catalytic material and modified fly ash floating bead composite porous catalytic material

A technology of powder catalytic materials and fly ash floating beads, which is applied in the field of material chemistry and can solve problems affecting applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~ Embodiment 4

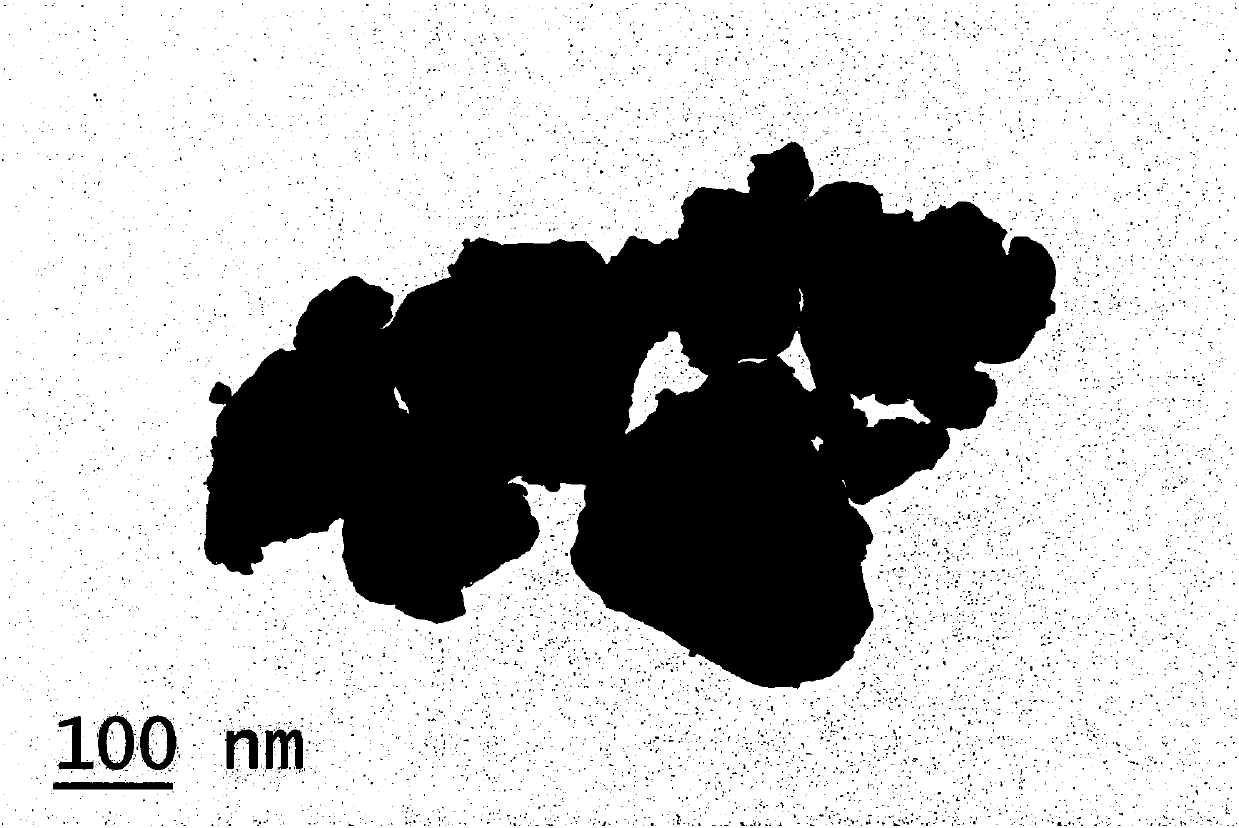

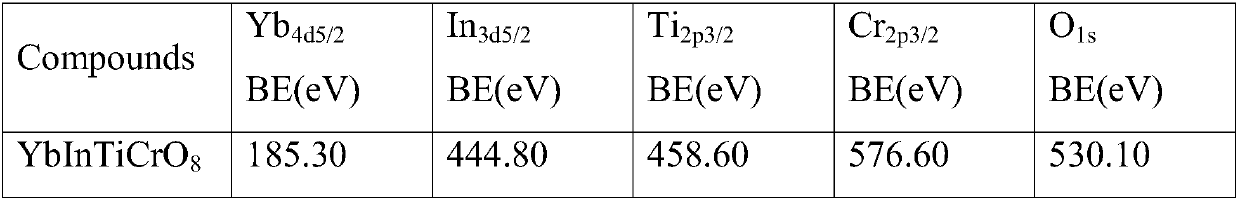

[0069] Examples 1 to 4 are YbInTiCrO 8 Preparation method of powder catalytic material

Embodiment 1

[0071] A preparation method of powder catalytic material includes a solid phase sintering method, and the specific steps are:

[0072] (1) According to Yb 2 O 3 , In 2 O 3 , TiO 2 And CrO 3 The molar ratio of is 1:1:2:2, respectively weigh the Yb with a purity of 99.99% 2 O 3 , In 2 O 3 , TiO 2 And CrO 3 , And mix it evenly, and then add it to a ball mill to grind to obtain a powder with a particle size of 1.5μm-3.0μm.

[0073] (2) Take the above powder and dry it at 170℃-230℃ for 2.5h-3.5h, press it into a tablet, put it in a high-temperature sintering furnace, and sinter it. The sintering process is: first raise the furnace temperature to 370℃- Keep the temperature at 430°C for 3h-5h; then cool with the furnace to obtain the first sintered tablet.

[0074] (3) Take the above-mentioned first sintering tablet and crush it to obtain a powder with a particle size of 1.5μm-2.5μm, and then press it into a tablet; then put it into a high-temperature sintering furnace for sintering, the si...

Embodiment 2

[0078] A method for preparing powdered catalytic materials includes a self-propagating combustion method, and the specific steps are:

[0079] (a) According to Yb(NO 3 ) 3 ·5H 2 O, In(NO 3 ) 3 ·4.5H 2 O, Ti(NO 3 ) 4 And Cr(NO 3 ) 3 ·9H 2 The stoichiometric ratio of O is 1:1:1:1, glycine and Yb(NO 3 ) 3 ·5H 2 The molar ratio of O is 5:1. Weigh Yb(NO 3 ) 3 ·5H 2 O, In(NO 3 ) 3 ·4.5H 2 O, Ti(NO 3 ) 4 , Cr(NO 3 ) 3 ·9H 2 O and glycine, and dissolve them in deionized water;

[0080] (b) Place the above-mentioned mixed solution in a constant temperature magnetic stirrer and stir at 80°C. When the solution has evaporated to half, stop stirring and transfer the solution to a crucible;

[0081] (c) Put the above crucible in a muffle furnace, firstly heat up to 200°C at a rate of 5°C / min, and hold for 30 minutes; then heat up to 400°C at a rate of 2°C / min and hold for 60 minutes to make it self-propagating combustion ;

[0082] (d) Raise the burned product to 800°C at a rate of 9.5°C / min, hold ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com