Preparation method for water-soluble tamarindus indica polysaccharide

A tamarind polysaccharide and water-soluble technology is applied in the field of preparation of water-soluble tamarind polysaccharide, and can solve problems such as difficulty in meeting national standards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

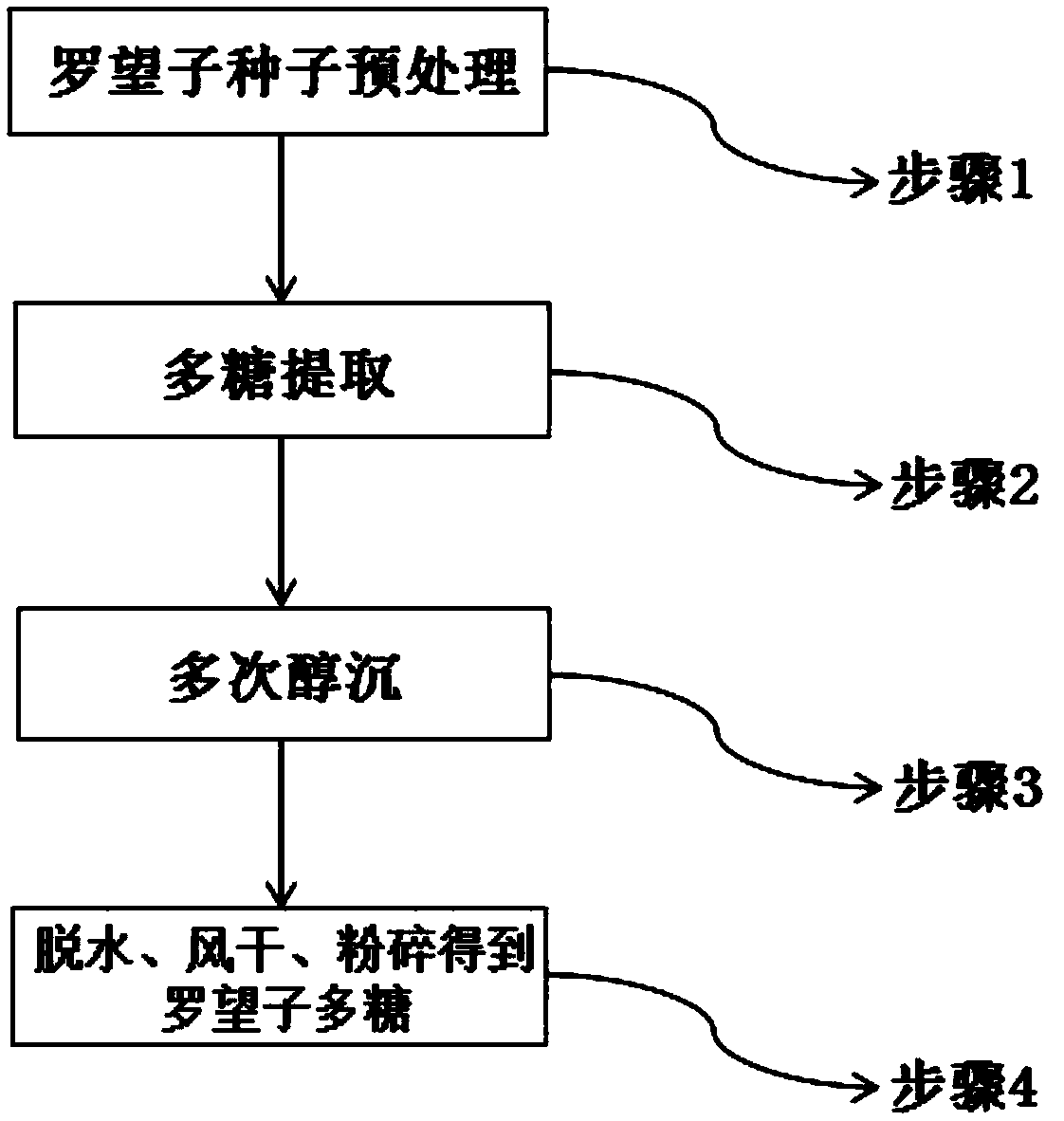

[0025] Embodiment one: if figure 1 Shown, the step that hot water method extracts tamarind polysaccharide is as follows:

[0026] Step 1, soak the tamarind seeds in water, dry with hot air, crush and peel, pulverize, and pass through a 60-mesh sieve to obtain a fine powder; take an appropriate amount of tamarind fine powder, add 75% ethanol according to a material-to-liquid ratio of 1:15, and stir for 12 hours. Centrifuge, precipitate and dry to obtain dry powder after removing ethanol;

[0027] Step 2: Weigh 100g of dry powder, add distilled water according to the ratio of material to liquid 1:45, heat and stir at 80°C for 20min, then increase the temperature to 100°C, boil for 5min to stop heating, cool and centrifuge to obtain the extract.

[0028] Step 3: Slowly add ethanol to the extract to make the final concentration of ethanol 50%, let stand for alcohol precipitation for 2 hours, centrifuge to obtain the precipitate, continue to dissolve the precipitate in water, and ...

Embodiment 2

[0031] Embodiment two: if figure 1 Shown, the step that citric acid solution (pH 4.6) extracts tamarind polysaccharide is as follows:

[0032] Step 1, soak the tamarind seeds in water, dry with hot air, crush and peel, pulverize, and pass through a 60-mesh sieve to obtain a fine powder; take an appropriate amount of tamarind fine powder, add 75% ethanol according to a material-to-liquid ratio of 1:15, and stir for 12 hours. Centrifuge, precipitate and dry to obtain dry powder after removing ethanol;

[0033] Step 2, weigh 100g of dry powder, add distilled water according to the ratio of material to liquid 1:45, adjust the pH to 4.6 with high-concentration citric acid solution, heat and stir at 80°C for 15min, then increase the temperature to 100°C, and boil for 5min Stop heating, cool and centrifuge to obtain the extract.

[0034] Step 3, slowly add ethanol to the extract to make the final concentration of ethanol 50%, let stand for alcohol precipitation for 2 hours, centrif...

Embodiment 3

[0037] Embodiment three: as figure 1 Shown, the step that citric acid solution (pH 4.0) extracts tamarind polysaccharide is as follows:

[0038] Step 1, soak the tamarind seeds in water, dry with hot air, crush and peel, pulverize, and pass through a 60-mesh sieve to obtain a fine powder; take an appropriate amount of tamarind fine powder, add 75% ethanol according to a material-to-liquid ratio of 1:15, and stir for 12 hours. After centrifugation, the precipitate was dried to obtain a dry powder after removing ethanol.

[0039] Step 2, weigh 100g of dry powder, add distilled water according to the ratio of material to liquid 1:45, adjust the pH to 4.0 with high-concentration citric acid solution, heat and stir at 80°C for 25min, then increase the temperature to 100°C, and boil for 5min Stop heating, cool and centrifuge to obtain the extract.

[0040] Step 3, add ethanol to the extract to make the ethanol concentration 40%, then let stand for alcohol precipitation for 2 hours...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com