Method for detecting depression amount of laser stitch welding seam based on line structured light sensor

A technology of line structured light and detection method, which is applied to instruments, measuring devices, and optical devices, etc., can solve the problems of inability to meet the production inspection rhythm, low detection efficiency, etc., and achieves low processing unit requirements and good robustness. , the effect of easy miniaturization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

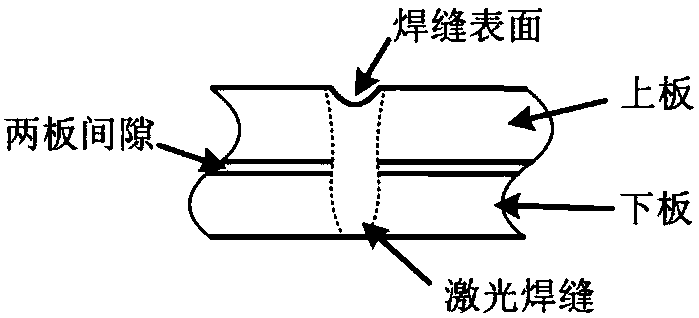

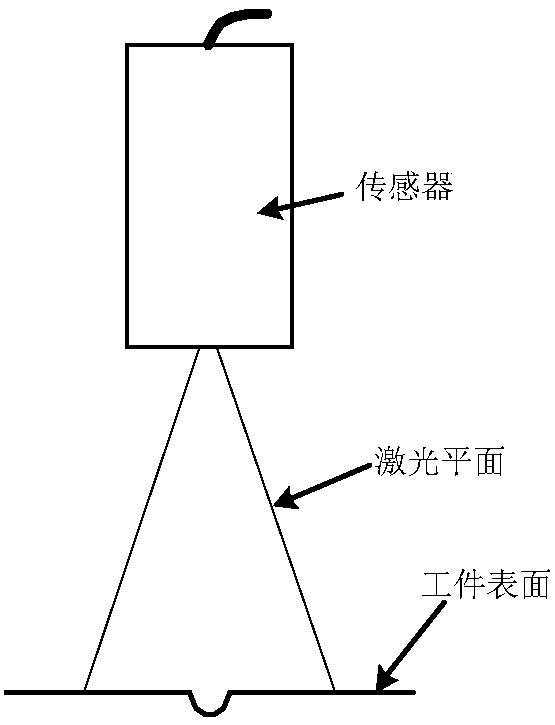

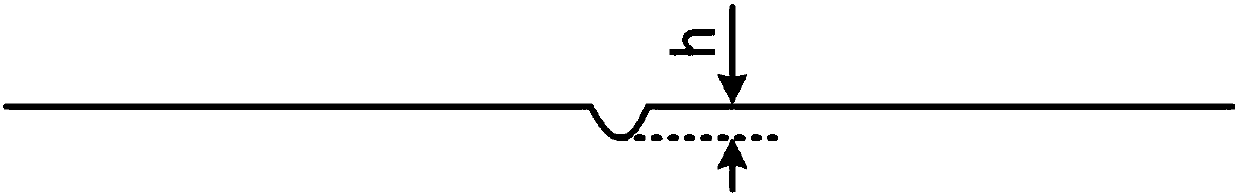

[0032] Specific implementation mode one, combination Figure 1 to Figure 6 In this embodiment, the method for detecting the concave amount of the laser stitch welding seam based on the line structure light sensor will be described when there is a gap between the two plates of the stitch welding joint ( figure 1 As shown), the surface of the weld will have a depression, and the amount of depression will directly affect the performance of the welded joint; figure 2 It is a schematic diagram when the line structure light sensor is used for scanning. The tooling ensures that the laser line is perpendicular to the weld direction when the light plane sensor is scanning. The amount of depression h( image 3 ) Is defined as the vertical distance from the surface of the workpiece to the bottom of the weld groove.

[0033] In actual measurement, it may appear as Figure 4 , Figure 5 The situation shown needs to be taken into consideration when designing the detection algorithm. Figure 4 ...

specific Embodiment approach 2

[0050] Embodiment 2. This embodiment is an example of the method for detecting the concave amount of the weld seam of laser stitch welding based on the line structure light sensor described in the embodiment 1: the line structure light sensor measures a certain laser overlap welding at a certain time Welds, the coordinates of the feature points obtained are P 1 (5,0), P 2 (15,-1), P 3 (15.5,-1.63), P 4 (16,-1), P 5 (26.01,-0.12), the feature point coordinates include Figure 4 The problem that the surface of the workpiece is not parallel to the bottom surface of the sensor, and Figure 5 The problem that the surface of the workpiece on both sides of the overlap welding seam is not parallel, according to the foregoing invention content (unit mm), then

[0051]

[0052]

[0053]

[0054]

[0055]

[0056] h=-0.61

[0057] According to this algorithm, it can be calculated that the concave amount of the laser stitch welding seam at the detection position at this time is 0.61mm. It can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com