Method for jointly determining silicon, aluminum, barium, manganese, phosphorus and iron in silicon-aluminum-barium by inductively coupled plasma

A plasma and inductive coupling technology, applied in the field of metallurgical chemical analysis and testing, can solve the problems of chemical reagents harmful to the human body and the environment, unable to meet production needs, low detection efficiency, etc. good precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

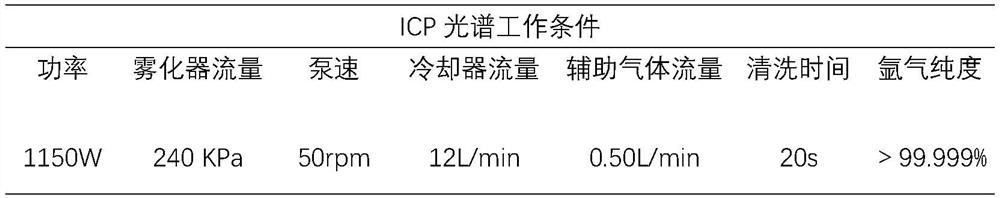

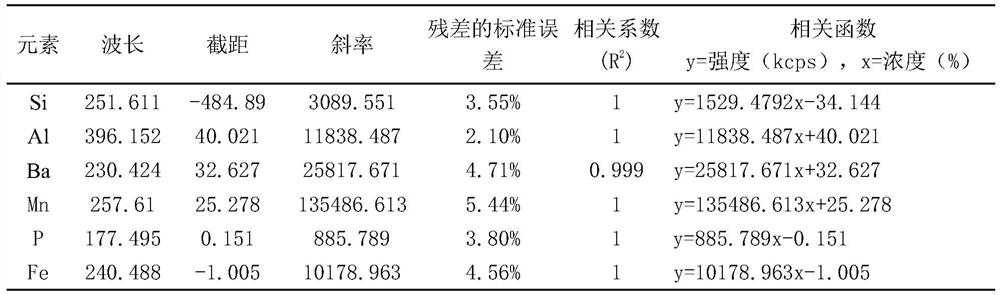

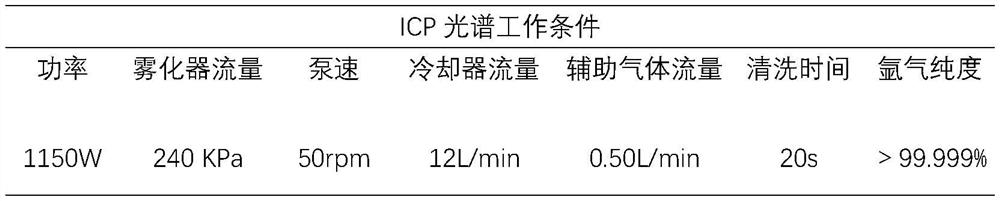

Method used

Image

Examples

Embodiment 1

[0036] The mensuration of embodiment 1 element content 1

[0037] S1 sample melting: adopt precision weighing equipment to take by weighing 0.1000g silicon aluminum barium sample that has been crushed through 120 mesh sieves, and the accuracy of weighing is accurate to 0.0001g; In a crucible with a 3:1 mixed flux, fully mix the sample with the mixed flux, then cover with 0.5g of sodium carbonate-boric acid mixed flux, cover the crucible lid, and melt in a high-temperature furnace at 950°C for 10 minutes until the sample melts into red When it is in a transparent melt state, take the sample out and cool to room temperature; take it out and cool to room temperature.

[0038] S2 sample acidification leaching: select a clean container without interference from impurities, clean it with tap water and deionized water in turn, transfer the crucible containing the sample and cooled to room temperature into the container, rinse the outer wall of the crucible with water, and rinse the c...

Embodiment 2

[0055] The mensuration of embodiment 2 element content 2

[0056] S1 sample melting: adopt precision weighing equipment to take by weighing 0.2000g silicon-aluminum-barium sample that has been crushed through a 120 mesh sieve, and the accuracy of weighing is accurate to 0.0001g; In a crucible with a 3:1 mixed flux, fully mix the sample and the mixed flux, then cover with 1g of sodium carbonate-boric acid mixed flux, cover the crucible lid, and melt in a high-temperature furnace at 950°C for 10 minutes, until the sample melts into red and transparent In the melt state, take the sample out and cool to room temperature; take it out and cool to room temperature.

[0057] S2 sample acidification leaching: select a clean container without interference from impurities, clean it with tap water and deionized water in turn, transfer the crucible containing the sample and cooled to room temperature into the container, rinse the outer wall of the crucible with water, and rinse the contain...

Embodiment 3

[0074] The mensuration of embodiment 3 element content 3

[0075] S1 sample melting: adopt precision weighing equipment to take by weighing 0.3000g silicon aluminum barium sample that has been crushed through a 120 mesh sieve, and the accuracy of weighing is accurate to 0.0001g; In a crucible with a 3:1 mixed flux, fully mix the sample with the mixed flux, then cover with 1.5g of sodium carbonate-boric acid mixed flux, cover the crucible lid, and melt in a high-temperature furnace at 950°C for 10 minutes until the sample melts into red When it is in a transparent melt state, take the sample out and cool to room temperature; take it out and cool to room temperature.

[0076] S2 sample acidification leaching: select a clean container without interference from impurities, clean it with tap water and deionized water in turn, transfer the crucible containing the sample and cooled to room temperature into the container, rinse the outer wall of the crucible with water, and rinse the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com