Improved high-voltage alternating current pulse sludge decomposing device and application thereof

A high-voltage AC and sludge decomposition technology, which is applied in sludge treatment, electrochemical sludge treatment, water/sludge/sewage treatment, etc., to increase the generation area of high-voltage AC pulse electric field, to treat a large amount of sludge, and to improve effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be further described below in conjunction with the examples, but not as a limitation to the present invention. The scope of protection of the present invention is based on the contents of the claims. Any equivalent technical means replacement made according to the description will not depart from the scope of the present invention. protected range.

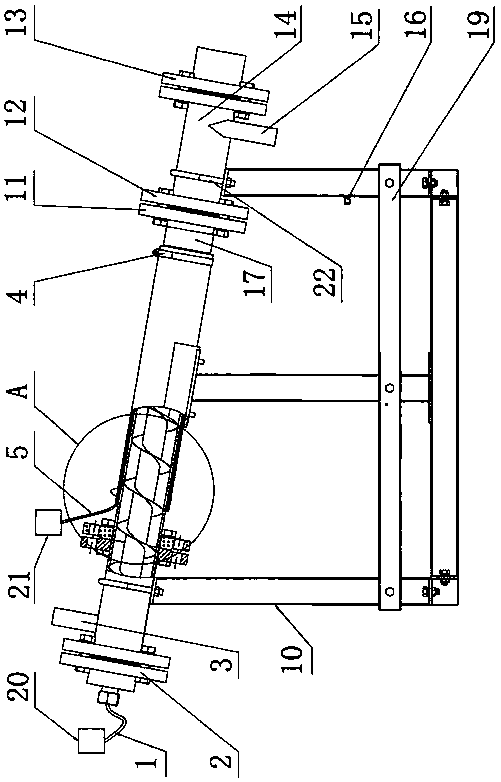

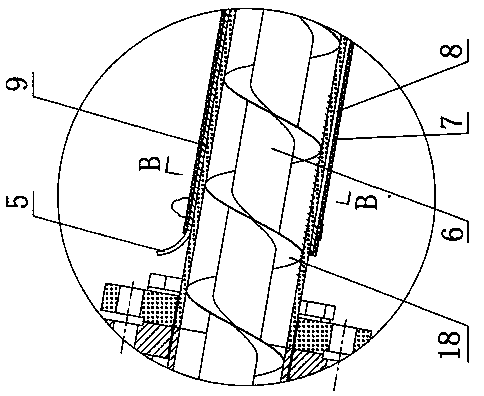

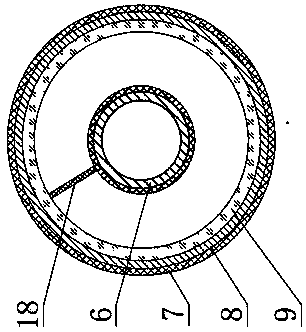

[0052] The overall structure of this embodiment is shown in the figure, wherein the improved high-voltage AC pulse sludge decomposition device includes a sludge flow pipe 9, an electrode and a high-voltage AC pulse power supply electrically connected thereto, and the two ends of the sludge flow pipe 9 are connected The flanges are respectively connected to metal pipes 14; the electrodes include an inner electrode 6 fixed in the sludge flow pipe 9 along the axis and coated with an insulating sheath on the outer surface, and an outer electrode 8 coated on the outer surface of the sludge flow pipe 9; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com