Waterproof glass coating liquid and preparation process thereof

A technology of coating liquid and glass, applied in the direction of coating, etc., can solve the problems of non-waterproof performance, achieve the effects of improving drainage performance, strengthening anti-fouling ability and self-cleaning ability, and reducing permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

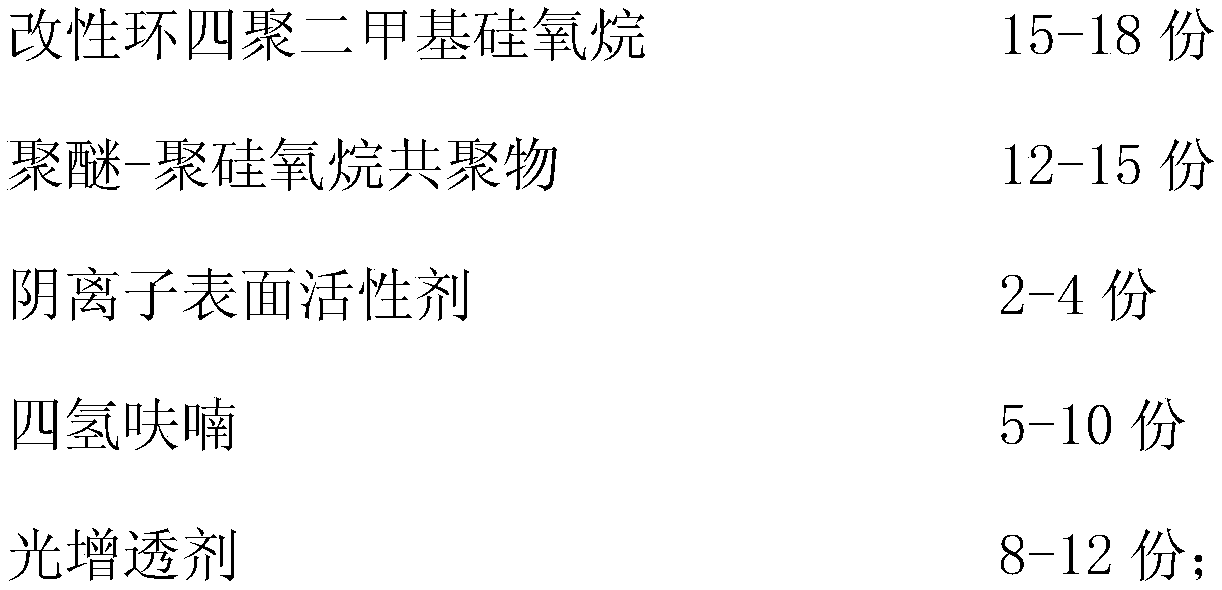

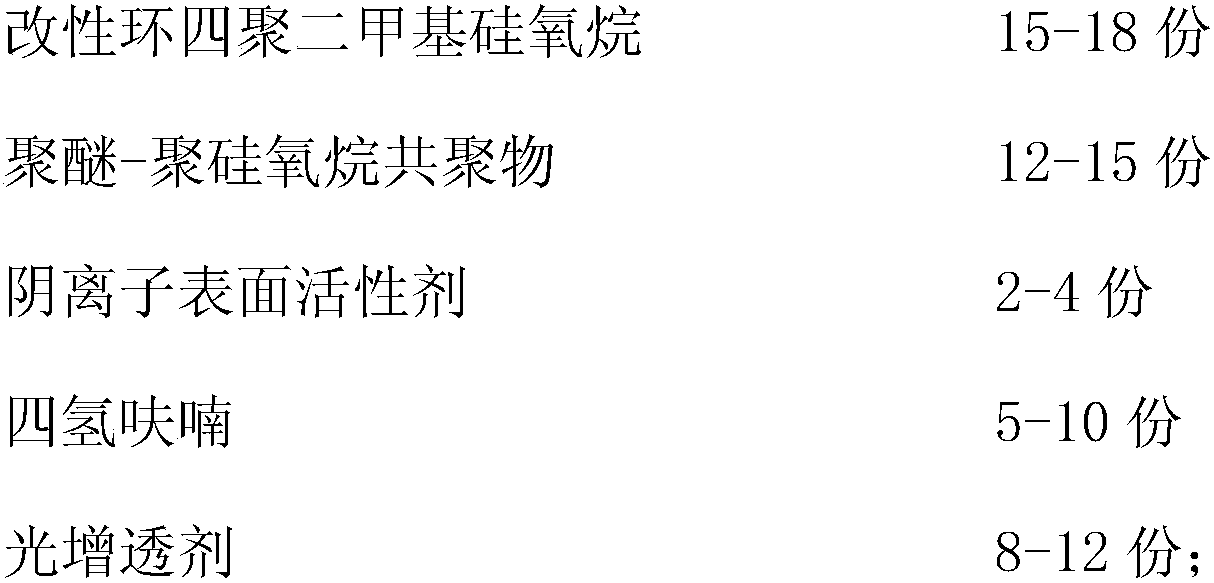

Embodiment 1

[0020] Step 1: After irradiating cyclotetramethicone with 50 rem gamma rays for 10 minutes, the modified cyclotetramethicone was obtained. At 60°C, 15 parts of modified cyclotetramethicone base siloxane and 12 parts of polyether-polysiloxane copolymers were stirred for 30 minutes to obtain a superhydrophobic medium;

[0021] Step 2: According to the weight ratio of 1.5:2:0.5:1 BiO 3 、TiO 2 , ZrO 2 and MgF 2 Placed in a nitrogen environment with a pressure of 2 Pa, calcined at 400°C for 2 hours, pulverized, and passed through a 300-mesh sieve to obtain an optical anti-reflection agent;

[0022] Step 3: At 40°C, disperse the superhydrophobic medium in 5 parts of tetrahydrofuran, and after ultrasonication for 20 minutes, mix evenly with 8 parts of optical anti-reflection agent and 2 parts of polyacrylamide to obtain a waterproof glass coating solution.

Embodiment 2

[0024] Step 1: After irradiating cyclotetramethicone with 100 rem gamma rays for 12 minutes, the modified cyclotetramethicone was obtained. At 70°C, 16 parts of the modified cyclotetramethicone base siloxane and 13 parts of polyether-polysiloxane copolymer were stirred for 35min to obtain a superhydrophobic medium;

[0025] Step 2: According to the weight ratio of 1.75:2.5:0.75:1.5 BiO 3 、TiO 2 , ZrO 2 and MgF 2 Placed in a nitrogen environment with a pressure of 3 Pa, calcined at 450°C for 2.5 hours, pulverized, and passed through a 350-mesh sieve to obtain an optical anti-reflection agent;

[0026] Step 3: At 45°C, disperse the super-hydrophobic medium in 7 parts of tetrahydrofuran, and after ultrasonication for 25 minutes, mix evenly with 10 parts of optical anti-reflection agent and 3 parts of sodium dodecylbenzenesulfonate to obtain a waterproof glass coating solution.

Embodiment 3

[0028] Step 1: After irradiating cyclotetramethicone with 150 rem gamma rays for 15 minutes, the modified cyclotetramethicone was obtained. At 80°C, 18 parts of the modified cyclotetramethicone base siloxane and 15 parts of polyether-polysiloxane copolymer were stirred for 40 minutes to obtain a superhydrophobic medium;

[0029] Step 2: Mix BiO with a weight ratio of 2:3:1:2 3 、TiO 2 , ZrO 2 and MgF 2 Placed in a nitrogen environment with a pressure of 4 Pa, calcined at 500°C for 3 hours, pulverized, and passed through a 400-mesh sieve to obtain an optical anti-reflection agent;

[0030] Step 3: Disperse the super-hydrophobic medium in 10 parts of tetrahydrofuran at 50°C, and after ultrasonication for 30 minutes, mix evenly with 12 parts of optical anti-reflection agent and 4 parts of sodium oleoyloxyethanesulfonate to obtain a waterproof glass coating solution.

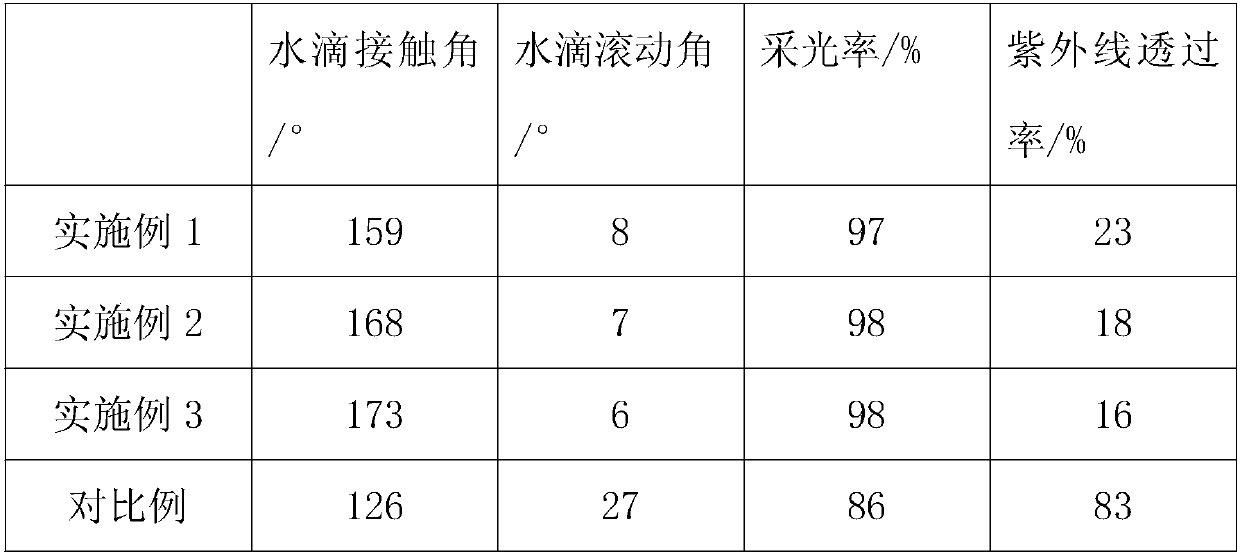

[0031] Embodiments 1, 2, and 3 are respectively used to coat and coat a layer of 5nm film on automobile glass,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com