Composite admixture for high-speed railway rail slab concrete

A composite admixture, high-speed railway technology, applied in the field of composite admixtures for high-speed railway track slab concrete, can solve the problems of track slab warping and deformation, production speed delay, high price, etc., to reduce curing temperature and improve early strength The effect of increasing and delaying the exothermic temperature peak of hydration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Mix each component material according to the following proportions to obtain the material of the present invention: sub-nano mineral material: 30%, specific surface area 600m 2 / kg ultrafine slag powder: 35%, glass beads: 32%, water reducer: 0.3%, polyether modified silicon defoamer: 0.2%, activator: 1.0%, nano silica: 1.0% , enhancer: 0.5%.

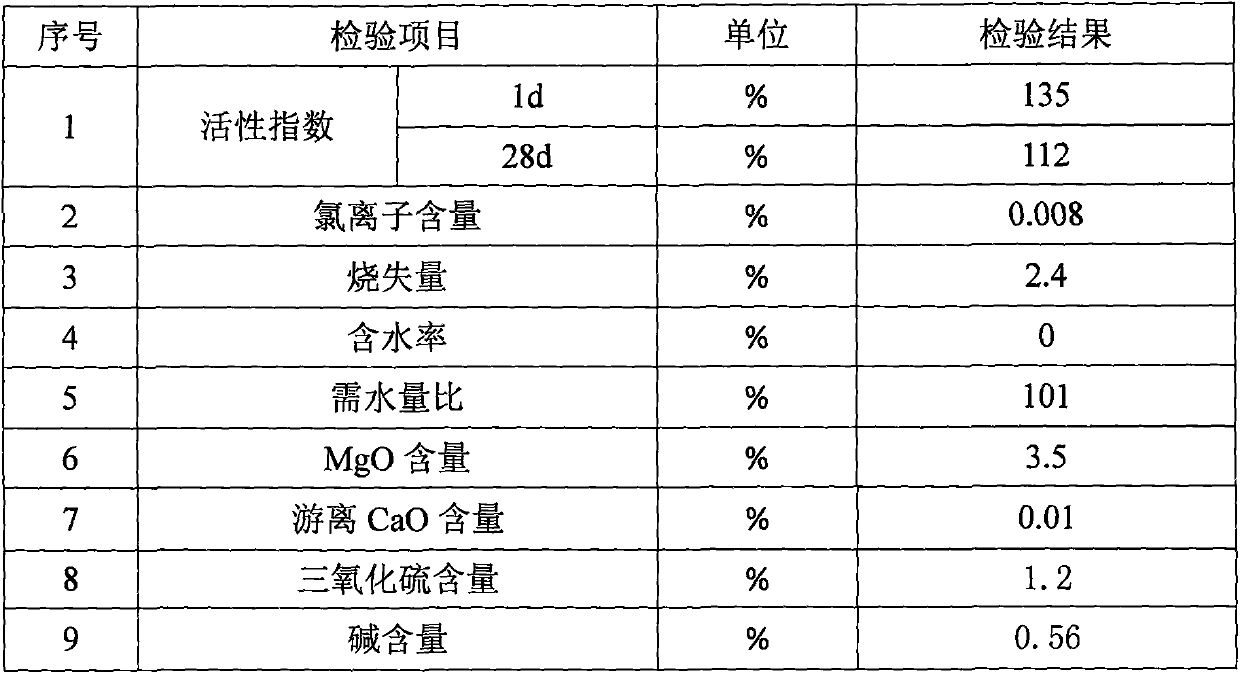

[0017] The performance of the material of the present invention that adopts above-mentioned prescription to make is shown in Table 1:

[0018] Table 1 Properties of composite admixtures

[0019]

Embodiment 2

[0021] Mix each component material according to the following ratio to obtain the material of the present invention: sub-nano mineral material: 34%, specific surface area 800m 2 / kg ultra-fine slag powder: 30%, glass beads: 32%, water reducer: 0.4%, silicone defoamer: 0.4%, activator: 1.0%, nano-silica: 1.4%, reinforcing agent : 0.8%.

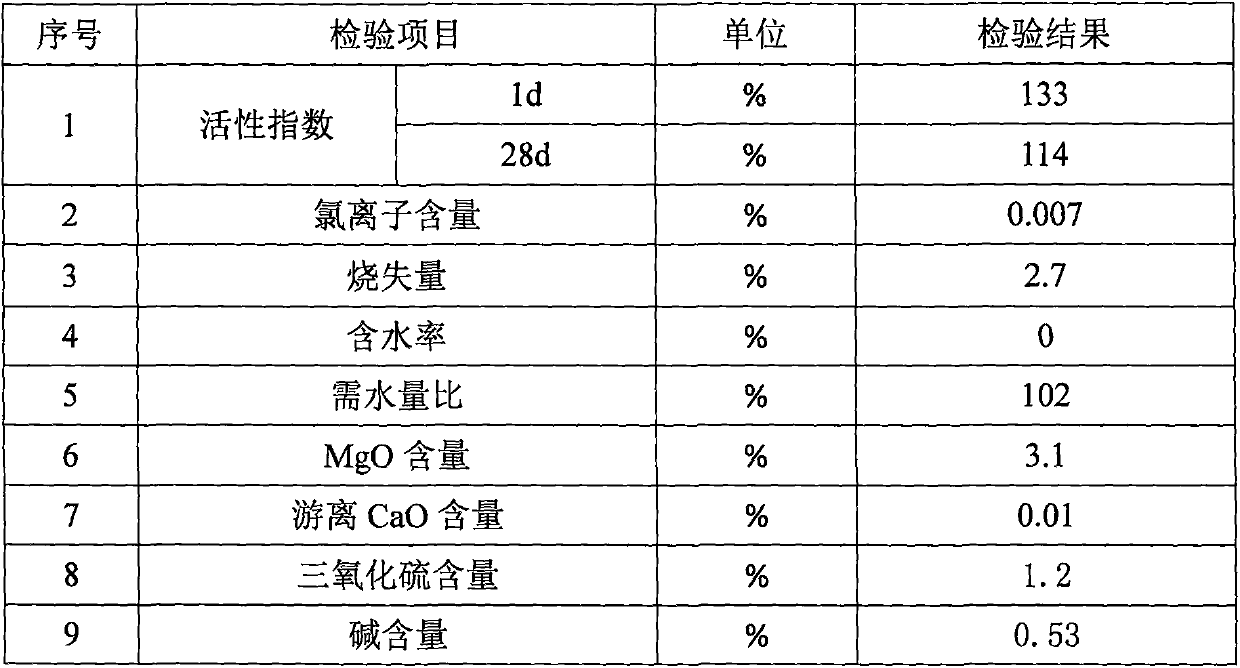

[0022] The performance of the material of the present invention that adopts above-mentioned prescription to make is shown in Table 2:

[0023] Table 2 Properties of composite admixtures

[0024]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com