Modified shell ash mortar and preparation method thereof

A shell ash and mortar technology, applied in the field of modified shell ash mortar and its preparation, can solve the problems of large shrinkage deformation, low hardening strength, slow setting and hardening, etc. The effect of increasing the amount of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

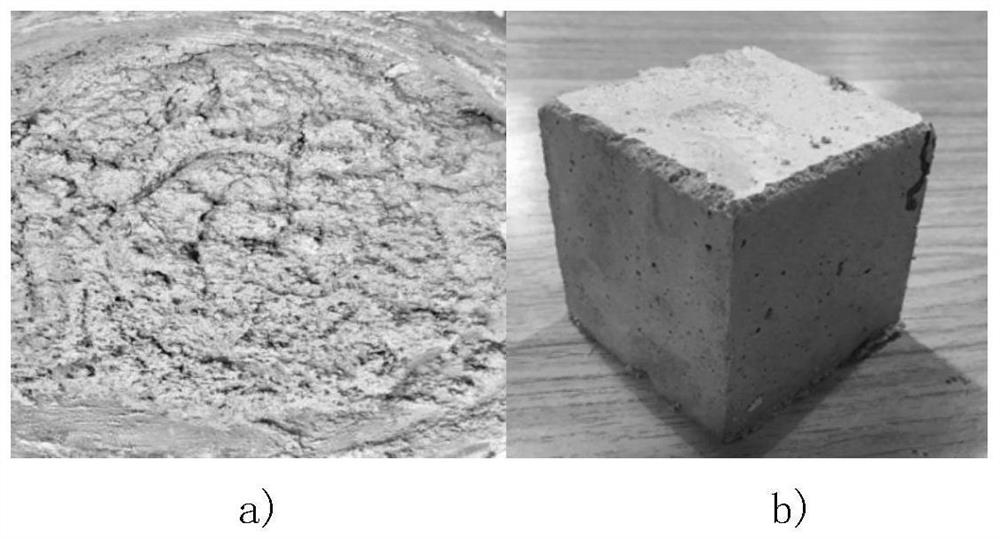

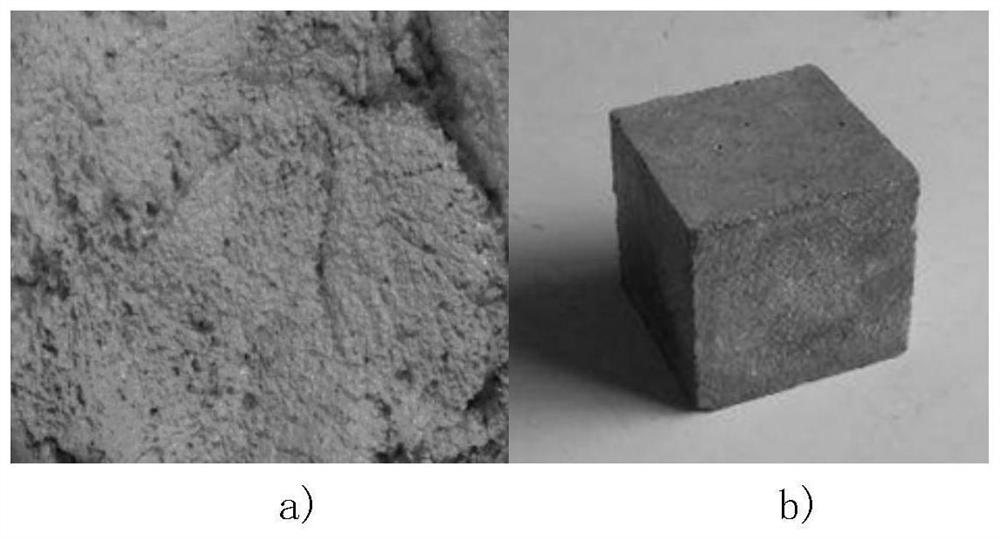

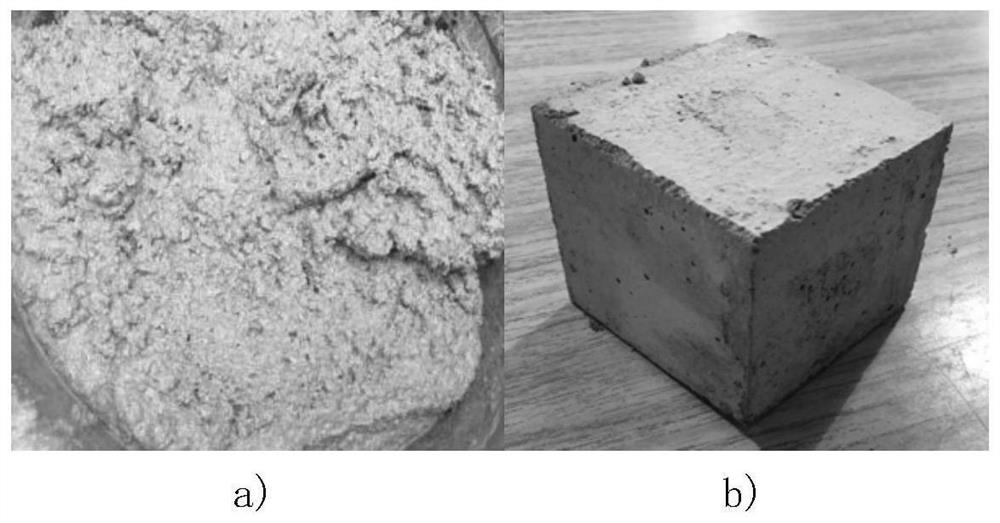

Image

Examples

Embodiment 1~3

[0061] The modified shell ash mortar includes the following raw materials in parts by mass: 0.6-0.8 parts of shell ash paste, 0.15-0.35 parts of mineral powder, 0.05 parts of silica fume, 2.5 parts of machine-made sand, and 0.2-0.3 parts of water. The specific mass proportions of Examples 1-3 are shown in Table 1.

[0062] The preparation method of above-mentioned modified shell ash mortar, comprises the following steps:

[0063] (1) Pour the oyster shell ash into a large plastic bucket, add 3 to 4 times of water to mature it, stir it evenly and settle it, and let it stand for more than 7 days to become a shell ash paste for use. During the aging period, keep a layer of moisture on the shell ash paste to isolate the shell ash paste from the air;

[0064] (2) Pull out the shell ash paste after aging, measure and adjust the consistency value of the shell ash paste in the range of 120mm ± 5mm;

[0065] (3) Accurately weigh the consumption of shell ash paste, mineral powder, sil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com