Medium-and-low-temperature epoxy resin and preparation method and application thereof in big-and-small-tow carbon fiber epoxy composite transmission shaft

A technology of curing epoxy resin and tow carbon fiber, which is applied in the direction of shafts, bearings, mechanical equipment, etc., can solve the problems of difficult preparation of composite transmission shafts, poor resin impregnation and wrapping capabilities, and difficult fiber composite materials, etc., to improve interface bonding Strength and cohesion, short cure cycle, increased mechanical properties and durability effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

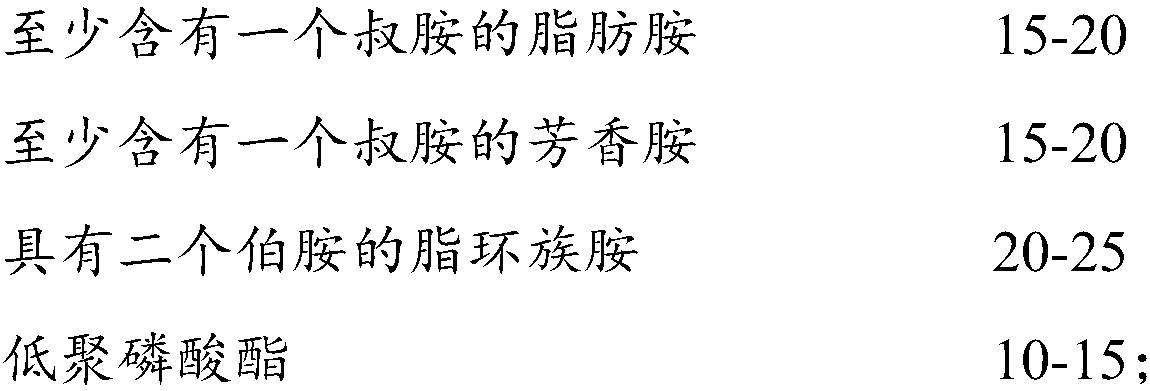

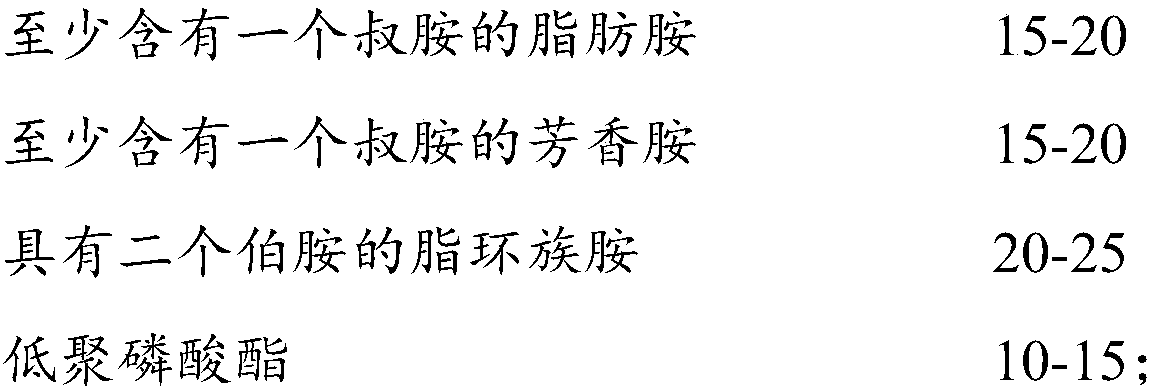

[0035] Medium and low temperature curing epoxy resin, composed of:

[0036] 10 parts by weight of nano-modified bisphenol A type epoxy resin, 60 parts by weight of novolak epoxy resin and 10 parts by weight of triglycidyl tripolyisocyanate;

[0037] Group B consisting of 20 parts by weight of tetraethylhexamethylenediamine, 20 parts by weight of 2-(dimethylaminomethyl) phenol, 25 parts by weight of menthanediamine, and 10 parts by weight of oligomeric phosphate (the number average molecular weight is 800) point.

[0038] The application of the above medium and low temperature curing epoxy resin in the preparation of large and small tow carbon fiber epoxy composite drive shafts:

[0039] (1) After the aluminum alloy mandrel is polished and cleaned twice, the surface is coated with a release agent and installed on the winding machine;

[0040] (2) Put the medium and low temperature curing epoxy resin into the dipping tank of the winding equipment, and heat it to 55°C, and impr...

Embodiment 2

[0045] Medium and low temperature curing epoxy resin, composed of:

[0046] 10 parts by weight of nano-modified bisphenol A type epoxy resin, 70 parts by weight of novolac epoxy resin and 10 parts by weight of triglycidyl tripolyisocyanate;

[0047] Group B consisting of 15 parts by weight of trimethylhexamethylenediamine, 20 parts by weight of 2-(dimethylaminomethyl) phenol, 20 parts by weight of menthanediamine, and 10 parts by weight of oligomeric phosphate (the number average molecular weight is 1000) point.

[0048] The application of the above medium and low temperature curing epoxy resin in the preparation of large and small tow carbon fiber epoxy composite drive shafts:

[0049] (1) After the aluminum alloy mandrel is polished and cleaned twice, the surface is coated with a release agent and installed on the winding machine;

[0050] (2) Put the medium and low temperature curing epoxy resin into the dipping tank of the winding equipment, and heat it to 55°C, and impr...

Embodiment 3

[0055] Medium and low temperature curing epoxy resin, composed of:

[0056] 10 parts by weight of nano-modified bisphenol A type epoxy resin, 65 parts by weight of novolac epoxy resin and 15 parts by weight of tetraglycidyl diaminodiphenylmethane component A;

[0057] Group B consisting of 15 parts by weight of tetraethylhexamethylenediamine, 20 parts by weight of 2-(dimethylaminomethyl) phenol, 25 parts by weight of menthanediamine, and 10 parts by weight of oligomeric phosphate (the number average molecular weight is 1000) point.

[0058] The application of the above medium and low temperature curing epoxy resin in the preparation of large and small tow carbon fiber epoxy composite drive shafts:

[0059] (1) After the aluminum alloy mandrel is polished and cleaned twice, the surface is coated with a release agent and installed on the winding machine;

[0060] (2) Put the medium and low temperature curing epoxy resin into the dipping tank of the winding equipment, and heat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com