A kind of eh36 extra-thick plate for high heat input welding with normalized delivery and its preparation method

A technology for high-energy welding and extra-thick steel plates, applied in the field of extra-thick steel plates, can solve the problems of decreased toughness of the base metal and heat-affected zone, unable to pin austenite grains, difficult to control, etc. The effect of fine-grain strengthening, excellent comprehensive mechanical properties, and the effect of increasing the content of acid-soluble aluminum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below with reference to the accompanying drawings, wherein the accompanying drawings constitute a part of the application and are used together with the embodiments of the present invention to explain the principles of the present invention.

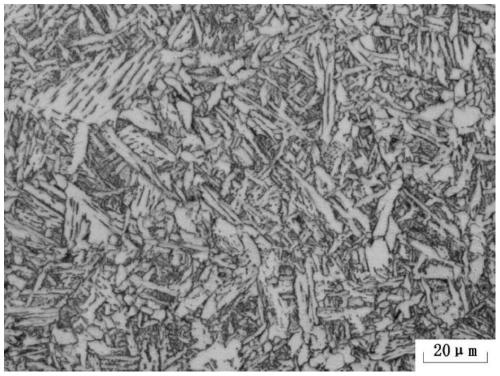

[0034] Figure 5 PF(I) is intragranular polygonal ferrite, and AF is acicular ferrite.

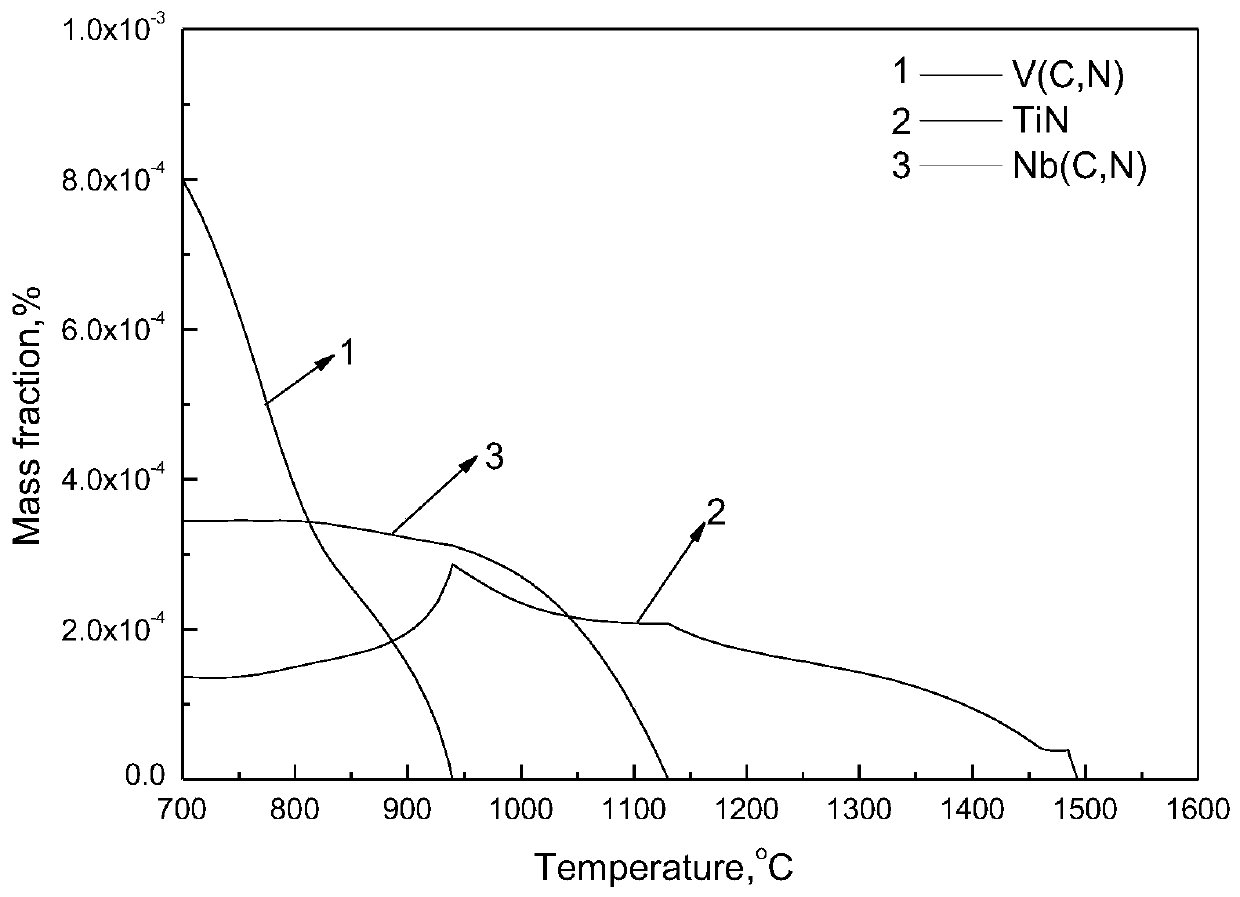

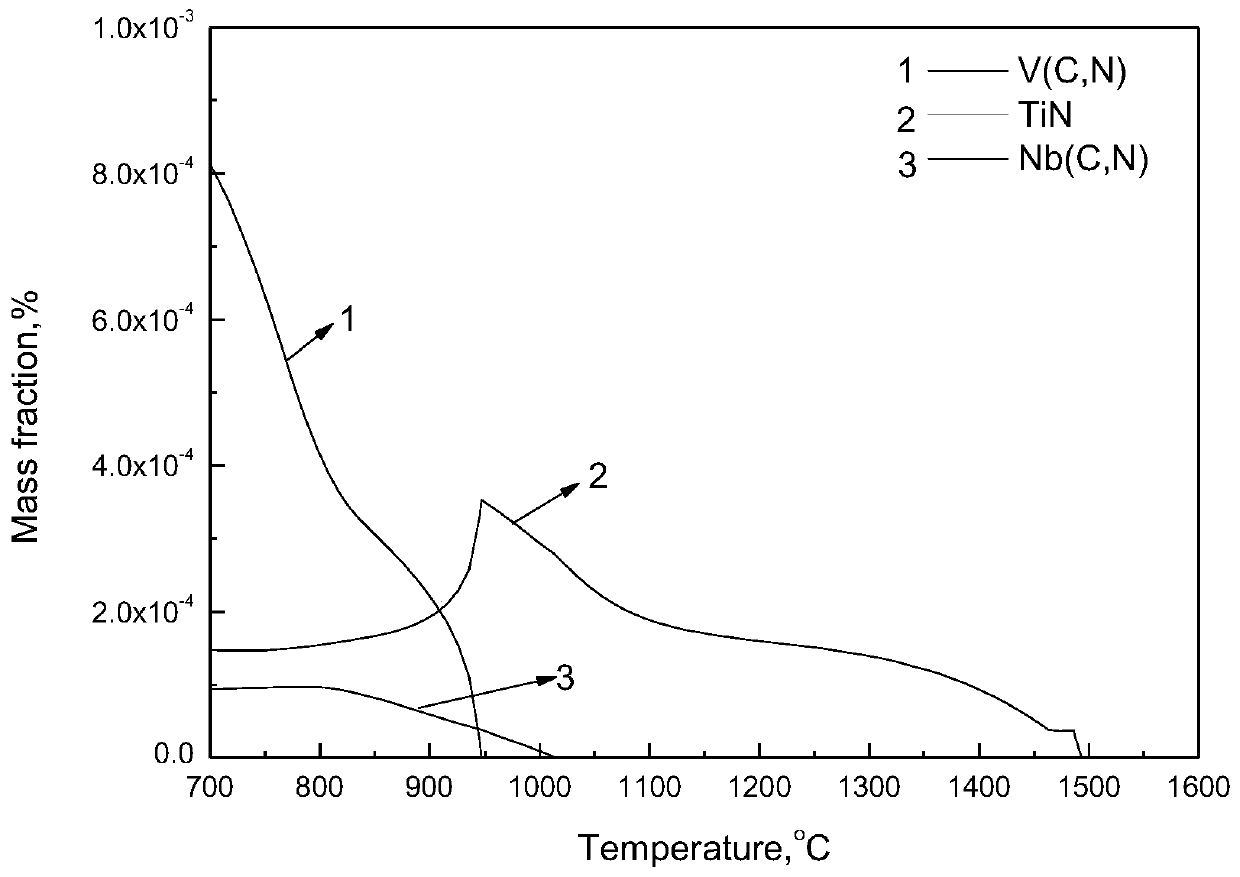

[0035] An EH36 extra-thick plate capable of large heat input welding delivered in a normalizing state and a preparation method thereof, comprising the following steps: the thickness of the continuous casting slab is 300mm, and the reheating temperature range of the continuous casting slab is 1150°C to 1180°C. In the rolling stage, the widening deformation temperature ranges from 1050°C to 1000°C. The rolling temperature range of the second stage is 950°C-900°C, the accumulated deformation is ≥30%, and the rolling deformation speed is less than 2m / s; the rolling deformation temperature of the thi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com