Closed type hydraulic rock drilling machine

A rock drill and closed technology, applied in the field of hydraulic rock drills and closed hydraulic rock drills, can solve problems such as threatening the physical and mental health of miners, increasing mine production costs, large energy, etc., to protect physical and mental health, reduce vibration, and reduce energy consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

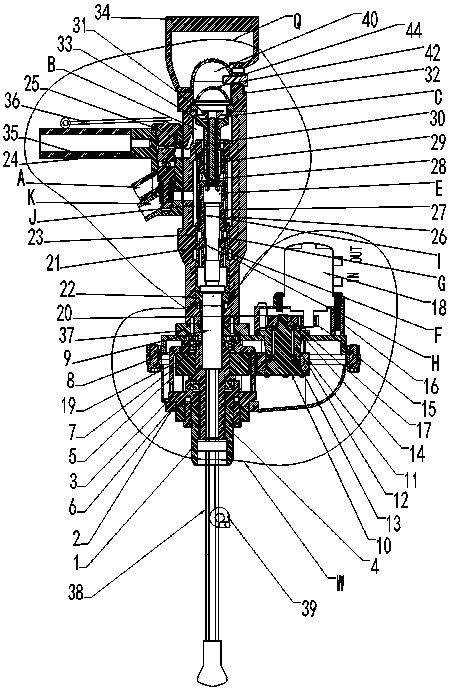

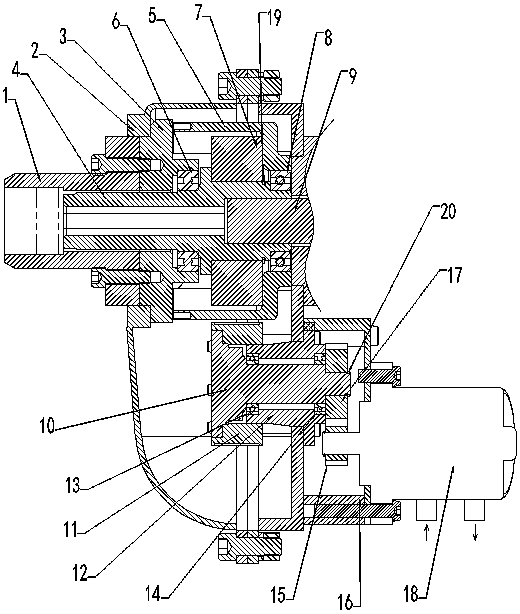

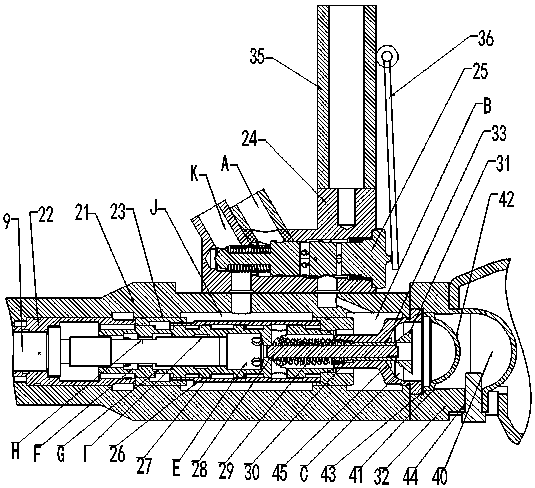

[0032] Examples such as Figure 1-Figure 3 As shown, a closed hydraulic rock drill includes an outer cover 2, and the outer cover 2 is provided with a shank 4 for fixing the tail end of the drill rod 38 and the piston 9, and the outer cover 2 is fixedly installed with a hydraulic motor 18, The hydraulic motor 18 drives the shank 4 to rotate through a three-stage transmission device. One end of the outer cover 2 is connected with an impact shell 21, and the impact shell 21 is provided with a buffer device to prevent the piston 9 from running dry.

[0033] The outer cover 2 is provided with a core body 5, and the shank 4 is installed in the core body 5. The front end of the core body 5 and the cover body of the outer cover 2 are sealed by a pressure plate 3, and the pressure plate 3 is set on the shank shank. 4 and is rotationally connected with the shank 4 through the first bearing 6 .

[0034] The rear end of the core body 5 is also rotationally connected to the shank 4 throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com