Pulsed detonation engine pressure back-propagation suppression structure

A pulse detonation and engine technology, applied in mechanical equipment, intermittent injection devices, etc., can solve the problems of mechanical valve response speed limit operating frequency, reliability is not guaranteed, mechanical fatigue of mechanical valves, etc., to avoid fatigue problems, reliable Enhanced performance and working frequency, short attenuation distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

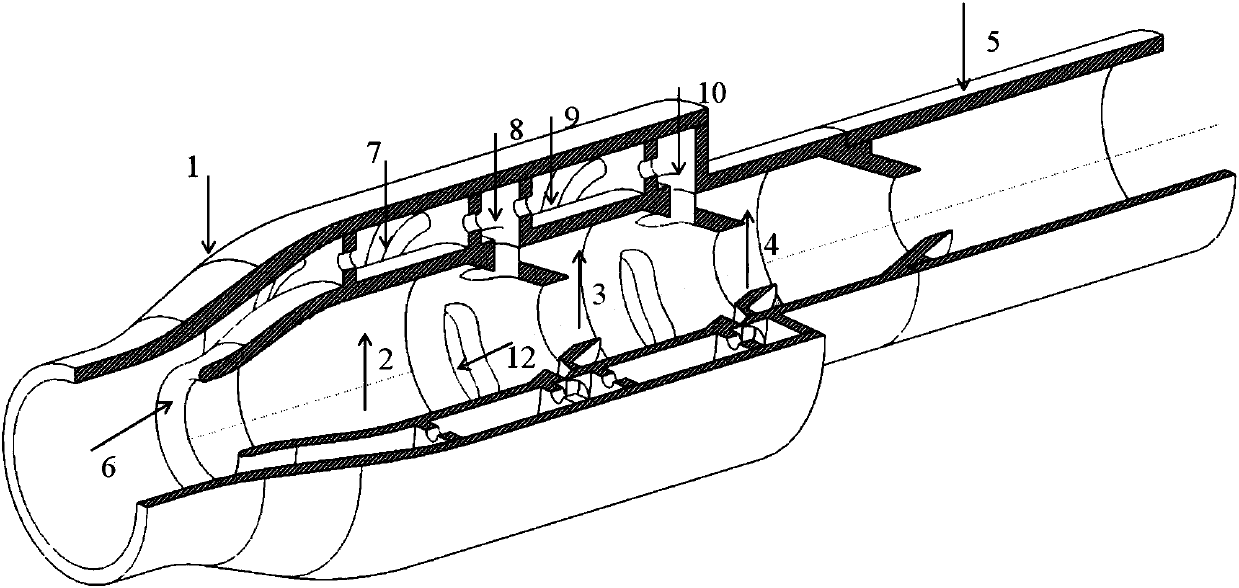

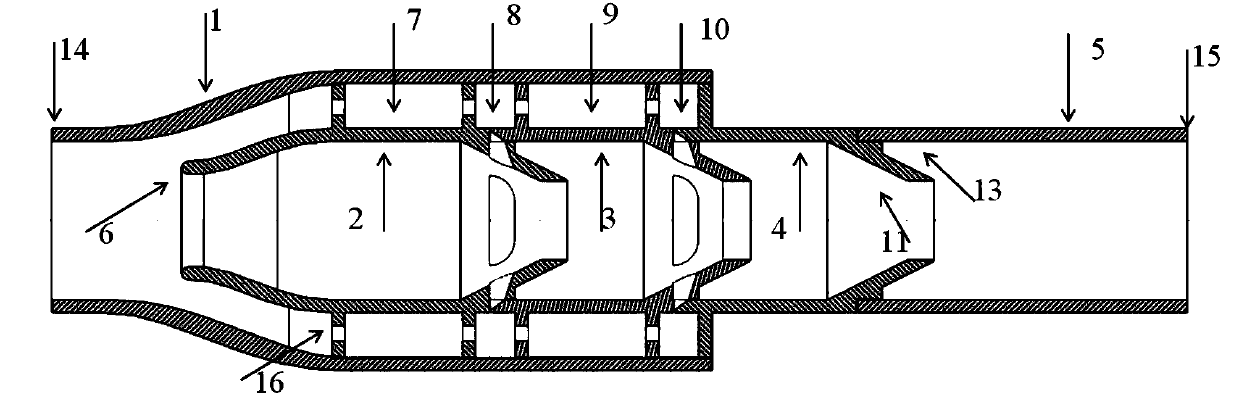

[0022] Example 1 as figure 2 As shown, a pulse detonation engine pressure reverse transmission suppression structure, when the pulse detonation engine is working, the ignition and detonation is carried out in the detonation tube (5) (the detonation wave is obtained through the transformation from deflagration to detonation or direct detonation initiation) , the detonation wave propagates to the front and rear ends respectively, and the detonation wave propagating in the opposite direction is called the back-propagation detonation wave. Since the back-propagation detonation wave is not supported by reactants, it will decouple or attenuate and become a shock wave or further attenuate into a compression wave. It is called the return wave; the return wave first interacts with the reflection cavity (13), forming a high pressure in the cavity, dissipating and reflecting a part of the return wave, and playing a role of suppressing the return pressure; the partially attenuated return ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com