Preparation method of silage leach liquor and application in silage detection

A technology of silage and extract, applied in the field of forage silage testing, can solve the problems of wasting laboratory resources, consuming a lot of manpower, material resources, time, and inaccurate data, etc., to shorten the experimental operation time and save laboratory consumables. , the effect of saving labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

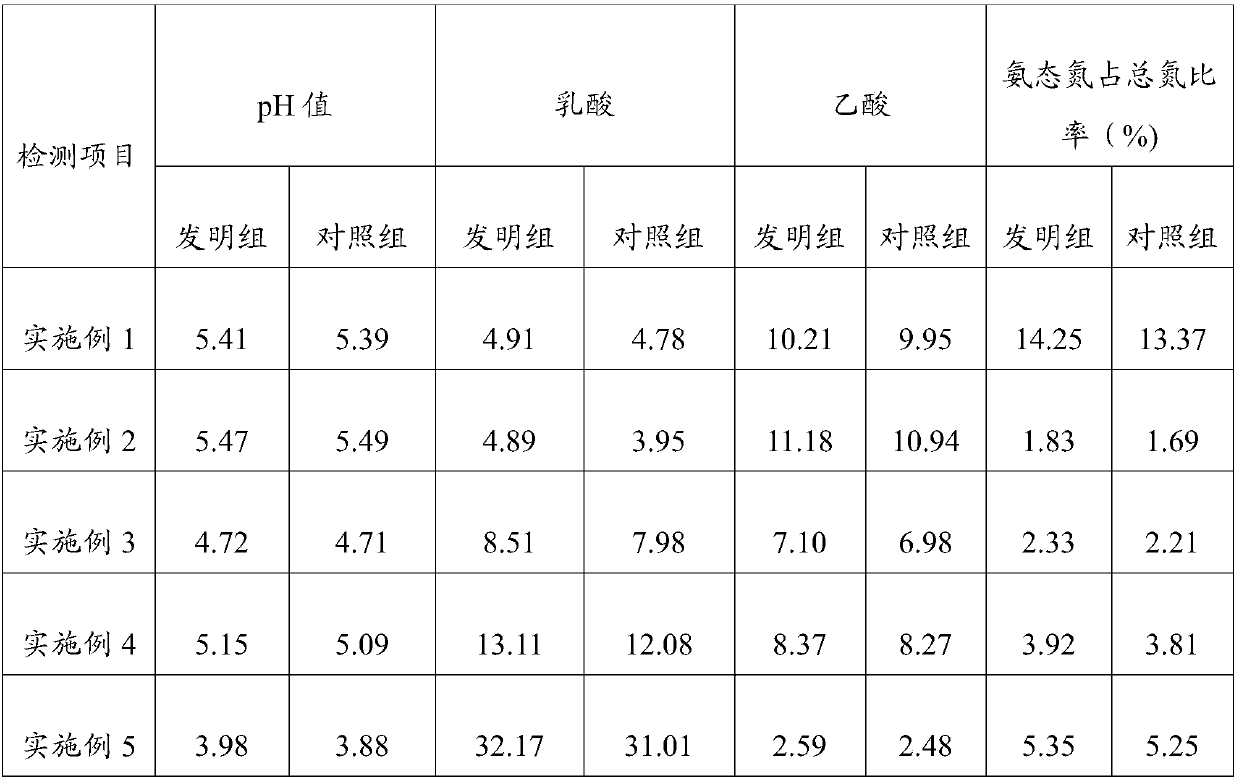

Examples

Embodiment 1

[0025] A method for preparing silage extract, specifically implemented according to the following steps:

[0026] Step 1: Add distilled water equivalent to 2 / 3 of the volume of the glass container into the glass container, seal the mouth of the glass container, then sterilize the glass container under high temperature and high pressure for 20 minutes, take it out after sterilization, and cool it down to room temperature naturally. Obtain sterilized distilled water;

[0027] Step 2, according to the mass ratio of sterilized distilled water to alfalfa silage of 8:1, add alfalfa silage into the sterilized distilled water of step 1 and seal and soak for 3 hours, and obtain the mixture after soaking;

[0028] Step 3, adding mass concentration to the mixture of step 2 is 1% hydrochloric acid solution, and the addition of hydrochloric acid solution is 1 / 20 of the quality of alfalfa silage, ultrasonic oscillation 3min after adding, wherein, the temperature of ultrasonic oscillation is...

Embodiment 2

[0031] A method for preparing silage extract, specifically implemented according to the following steps:

[0032] Step 1, add distilled water equivalent to 2 / 3 of the volume of the glass container into the glass container, seal the mouth of the glass container, and then sterilize the glass container under high temperature and high pressure for 25 minutes, take it out after the sterilization is completed, and cool it down to room temperature naturally. Obtain sterilized distilled water;

[0033] Step 2, according to the mass ratio of the sterilized distilled water and the Leymus chinensis silage being 9:1, the Leymus chinensis silage was added into the sterilized distilled water of the step 1 and sealed and soaked for 4 hours, and the mixture was obtained after soaking;

[0034] Step 3, add the hydrochloric acid solution that mass concentration is 1% to the mixture of step 2, and the addition amount of hydrochloric acid solution is 1 / 25 of the quality of Leymus chinensis silage...

Embodiment 3

[0037] A method for preparing silage extract, specifically implemented according to the following steps:

[0038] Step 1. Add distilled water equivalent to 2 / 3 of the volume of the glass container into the glass container, seal the mouth of the glass container, and then sterilize the glass container under high temperature and high pressure for 30 minutes. After the sterilization is completed, take it out and let it cool down to room temperature naturally. Obtain sterilized distilled water;

[0039] Step 2, according to the mass ratio of the sterilized distilled water and the stipa silage of 10:1, the stipa silage is added to the sterilized distilled water of step 1 and sealed and soaked for 5 hours, and the mixture is obtained after soaking;

[0040] Step 3, adding a mass concentration of 1% hydrochloric acid solution to the mixture in step 2, and the addition of the hydrochloric acid solution is 1 / 30 of the quality of Stipa silage silage, ultrasonic oscillation 5min after the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com