Preparation method of PSAF (polysilicate aluminum ferric) flocculant

A technology of polymerized ferric aluminum silicate and flocculant, which is applied in chemical instruments and methods, flocculation/sedimentation water/sewage treatment, water/sewage treatment, etc. It can solve the impact of polymerized ferric aluminum silicate flocculant and affect the flocculation effect, etc. problems, to achieve the effect of wide application range, good flocculation effect and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The preparation steps of polyaluminum iron silicate flocculant are as follows:

[0020] (1) Distilled water is heated to boiling, and the rotating speed is 300r / min and slowly drips the trimethylsiloxysilicate solution that mass concentration is 35%, and the rate of control drop rate is 1m1 / min, distilled water: trimethylsilane The volume ratio of the oxysilicate solution is 16:1. After the dropwise addition, continue to control the same rotation speed and stir for 30 minutes, add nano-silica, adjust the pH to 9 with a sodium hydroxide aqueous solution with a mass concentration of 8%, and heat and keep it warm. 3h, obtain silicic acid sol;

[0021] (2) Dividing the prepared silicic acid sol into three parts of silicic acid sol with a volume ratio of 3:2:1, followed by the first part of silicic acid sol, the second part of silicic acid sol and the third part of silicic acid sol, for subsequent use;

[0022] (3) In the first silicic acid sol, control the rotating speed t...

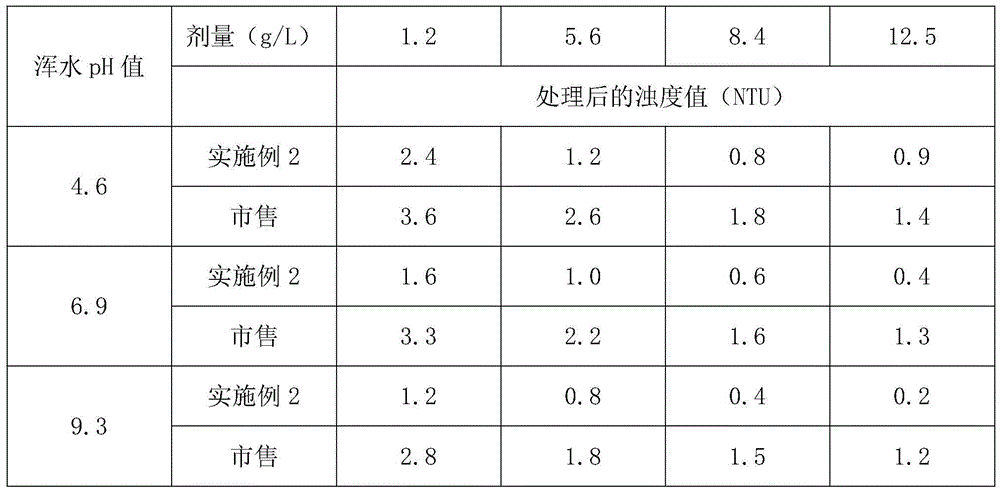

Embodiment 2

[0028] The preparation steps of polyaluminum iron silicate flocculant are as follows:

[0029] (1) The distilled water is heated to boiling, and the mass concentration is 40% trimethylsiloxysilicate solution slowly dripped under the speed of 400r / min, and the control rate of addition is 1.5m1 / min, distilled water: trimethyl The volume ratio of the siloxysilicate solution is 20:1. After the dropwise addition, continue to control the same rotation speed and stir for 40 minutes, add nano silicon dioxide, adjust the pH to 10 with a 10% sodium hydroxide aqueous solution, and heat Insulated for 4 hours to obtain silicic acid sol;

[0030] (2) Dividing the prepared silicic acid sol into three parts of silicic acid sol with a volume ratio of 3:2:1, followed by the first part of silicic acid sol, the second part of silicic acid sol and the third part of silicic acid sol, for subsequent use;

[0031] (3) In the first silicic acid sol, control the rotating speed to 300r / min, microwave h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com