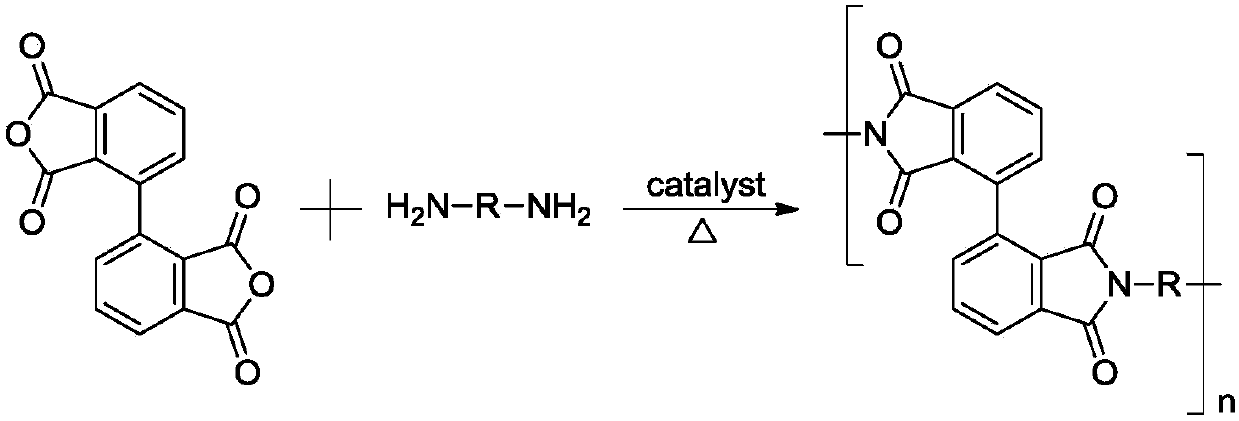

Application of polyimide in gas separation

A polyimide and gas separation technology, applied in the field of polymers, can solve the problems of limited application and low membrane permeability, and achieve the effects of high specific surface area, low cost and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

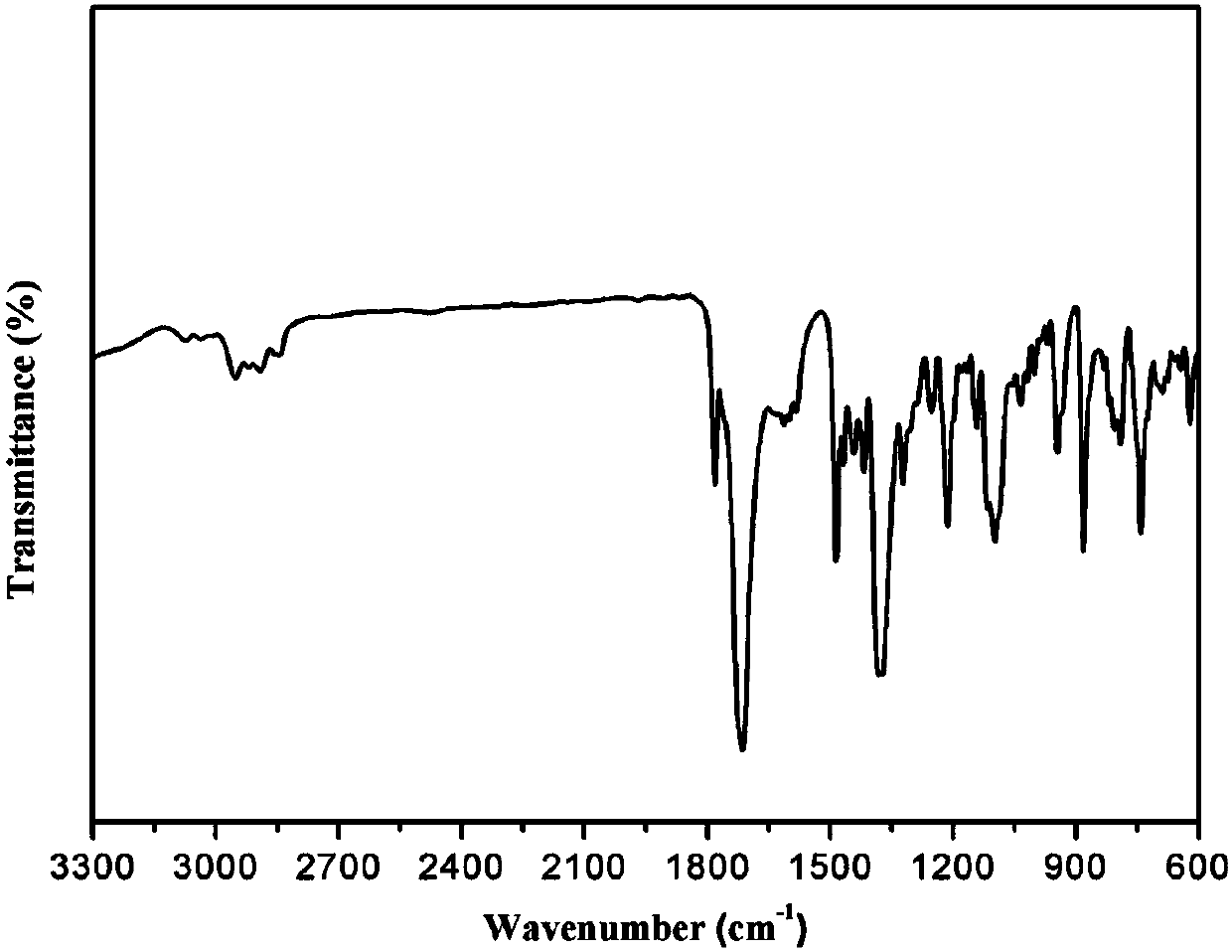

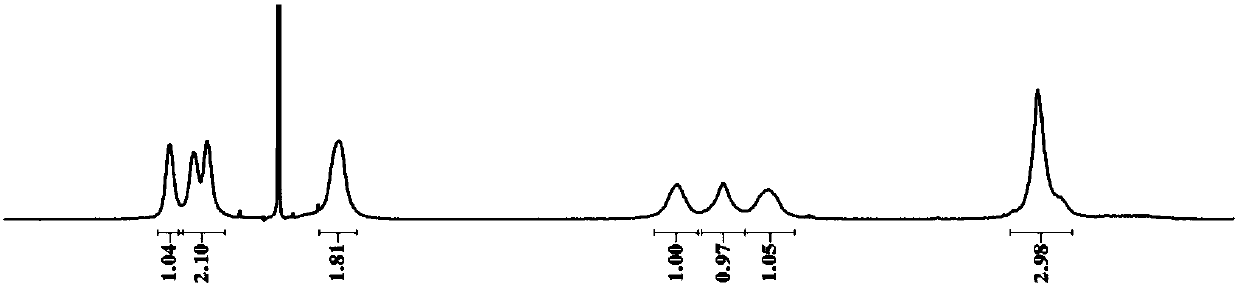

[0060] In the present embodiment, the structural formula of polyimide is as follows:

[0061]

[0062] The specific preparation method is: under the protection of nitrogen, add 1.4285g of 2,2',3,3'-biphenyltetracarboxylic dianhydride into a branch bottle, then add 2.45g of triethylamine and 15mL of ethanol, and heat to 80°C Stir magnetically until it is completely dissolved, and continue stirring under reflux for 1 hour after dissolution, then connect the water separator and increase the amount of nitrogen, take out the ethanol until the solution system becomes viscous and cannot be stirred by the magnet, add 0.7975g dissolved in 4mL N-methylpyrrolidone Tetramethyl-p-phenylenediamine, then add 1mL toluene, react at 80°C for one hour, then raise the temperature to 190°C, react for several hours until the reaction system becomes viscous and cannot be stirred, then cool down to 80°C and add 5mL N-methylpyrrolidone dilution. The solution was poured into ethanol to give a filam...

Embodiment 2

[0066] In the present embodiment, the structural formula of polyimide is as follows:

[0067]

[0068] The specific preparation method is: under the protection of nitrogen, add 0.8925g of 2,2',3,3'-biphenyltetracarboxylic dianhydride into a branch bottle, then add 1.53g of triethylamine and 15mL of ethanol, and heat to 80°C Stir magnetically until it is completely dissolved. After dissolving, continue to reflux and stir for 1 hour, then connect the water separator and increase the amount of nitrogen, take out the ethanol until the solution system becomes viscous and cannot be stirred by the magnet, add 0.7291g dissolved in 4mL N-methylpyrrolidone 3,3',5,5'-Tetramethylbenzidine, then add 1mL of toluene, react at 80°C for one hour, then raise the temperature to 190°C, react for several hours until the reaction system becomes viscous and cannot be stirred, then cool down to 80°C ℃ and add 5mL N-methylpyrrolidone for dilution. The solution was poured into ethanol to give a fil...

Embodiment 3

[0072] In the present embodiment, the structural formula of polyimide is as follows:

[0073]

[0074] The specific preparation method is: under the protection of nitrogen, add 0.7863g of 2,2',3,3'-biphenyltetracarboxylic dianhydride into a branch bottle, then add 1.35g of triethylamine and 15mL of ethanol, and heat to 80°C Stir magnetically until it is completely dissolved. After dissolving, continue to reflux and stir for 1 hour, then connect the water separator and increase the amount of nitrogen, take out the ethanol until the solution system becomes viscous and cannot be stirred by the magnet, add 0.9683g dissolved in 4mL N-methylpyrrolidone Add 2,2-bis(3-amino-4-methylphenyl)hexafluoropropane, then add 1mL of toluene, react at 80°C for one hour, then raise the temperature to 190°C, and react for several hours until the reaction system becomes viscous and cannot be stirred by the magnet Cool down to 80°C and add 5 mL of N-methylpyrrolidone to dilute. The solution was ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

| osmotic coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com