Ceramic material (titanium-tungsten-silicon-carbon) for connector of SOFC (solid oxide fuel cell)

A technology of solid oxide and ceramic materials, which is applied to fuel cell parts, fuel cells, circuits, etc., can solve problems such as thermal expansion mismatch, achieve high creep resistance, overcome a lot of waste, and good oxidation resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

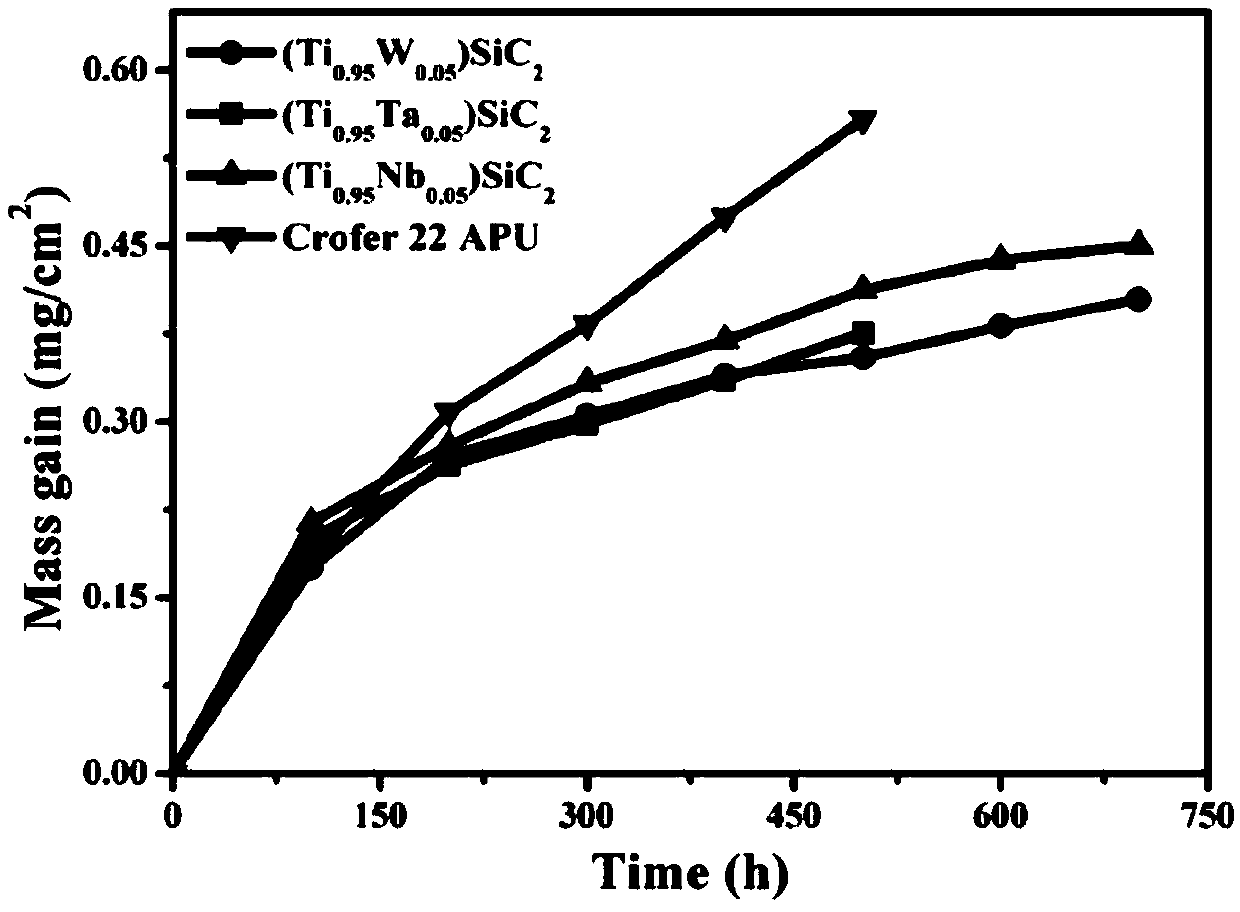

[0051] When x=0.05 in the chemical formula, the selected experimental material is titanium tungsten silicon carbon material (Ti 0.95 W 0.05 ) 3 SiC 2 , and its preparation process is as follows:

[0052] Ti, W, Si, and C element powders are used as synthetic materials. The above-mentioned material powders are prepared according to the ratio of 2.85:0.15:1:2. The raw powders are mixed with alcohol and put into a ball mill for ball milling. After 30 hours, it was taken out and sieved; it was cold-pressed in a graphite mold with a pressure of 10 MPa, and put into a hot-press furnace for hot-press synthesis. In the present invention, the technology adopted for the hot-pressing synthesis is: under the pressure of 70 MPa, heat preservation at 1650° C. for 60 minutes, and the reaction atmosphere is flowing Ar gas.

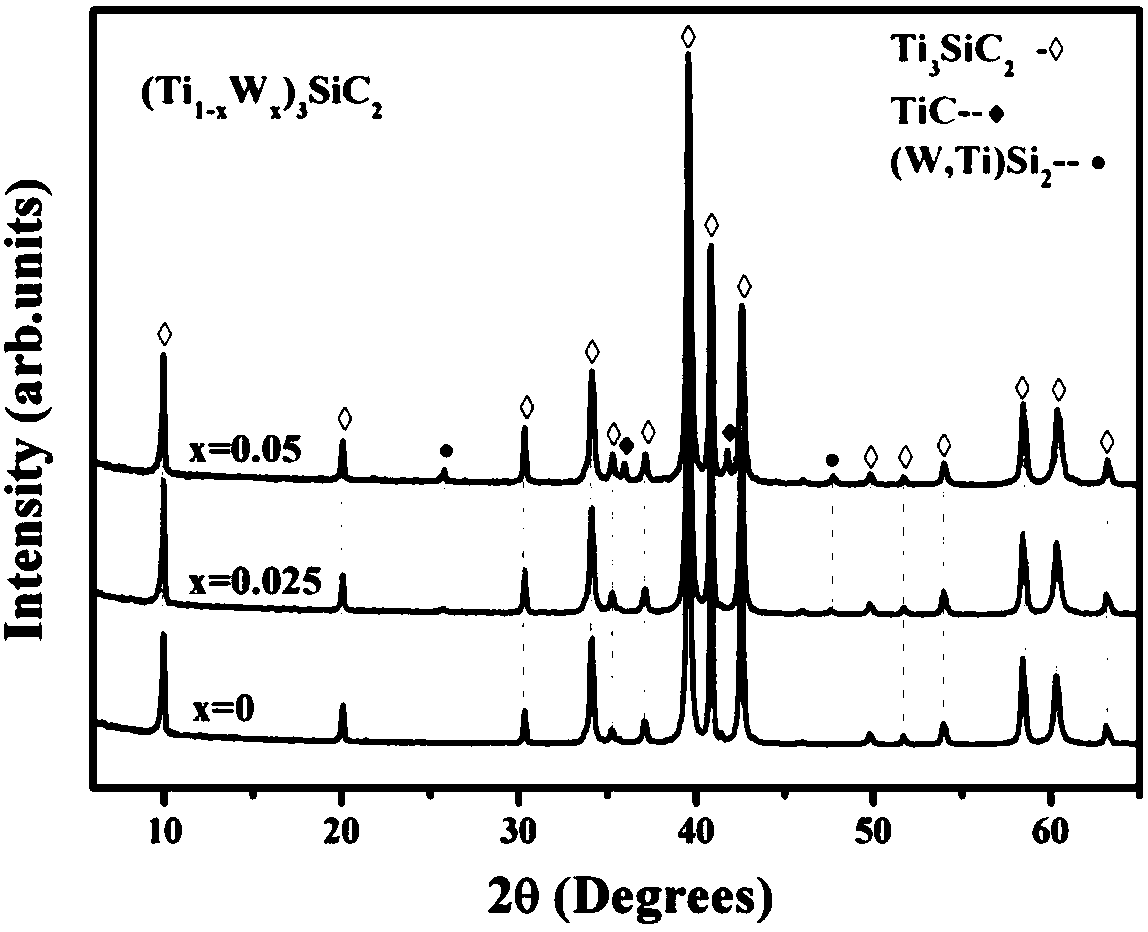

[0053] figure 1 The sintered dense (Ti 0.95 W 0.05 ) 3 SiC 2 XRD results of the bulk.

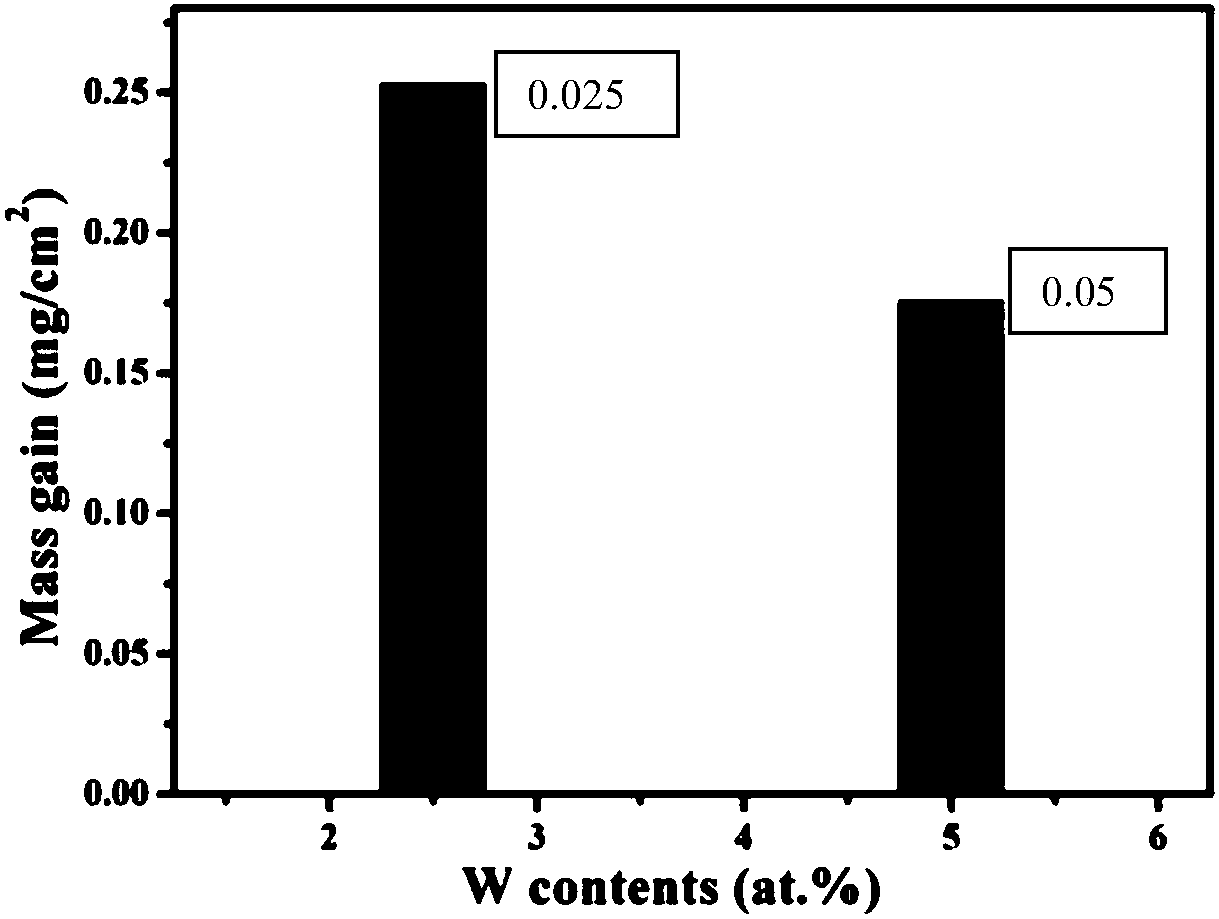

[0054] The density of the bulk material was measured to be 99.1%. Cut 1...

Embodiment 2

[0062] When x=0.025 in the chemical formula, the selected experimental material is titanium tungsten silicon carbon material (Ti 0.975 W 0.025 ) 3 SiC 2 , and its preparation process is as follows:

[0063] Ti, W, Si, and C element powders are used as synthetic materials. The above-mentioned material powders are prepared according to the ratio of 2.925:0.075:1:2. The prepared raw powders are mixed with alcohol and put into a ball mill for ball milling. After 24 hours, it was taken out and sieved; it was cold-pressed in a graphite mold with a pressure of 15 MPa, and put into a hot-press furnace for hot-press synthesis. In the present invention, the technology adopted for the hot-pressing synthesis is: under the pressure of 70 MPa, heat preservation at 1200° C. for 50 minutes, and the reaction atmosphere is flowing Ar gas. The density of the synthesized material is 97.6%.

[0064] figure 1 Medium is titanium tungsten silicon carbon material (Ti 0.975 W 0.025 ) 3 SiC 2 ...

Embodiment 3

[0068] When x=0.005 in the chemical formula, the selected experimental material is titanium tungsten silicon carbon material (Ti 0.995 W 0.005 ) 3 SiC 2 , and its preparation process is as follows:

[0069] Ti, W, Si, and C element powders are used as synthetic materials. The above-mentioned material powders are prepared according to the ratio of 2.985:0.015:1:2. The prepared raw powders are mixed with alcohol and put into a ball mill for ball milling. After 10 hours, it was taken out and sieved; it was cold-pressed in a graphite mold with a pressure of 5 MPa, and put into a hot-press furnace for hot-press synthesis. In the present invention, the process adopted for hot-pressing synthesis is: under 20MPa pressure, heat preservation at 1680°C for 20 minutes, then heat preservation at 1400°C for 80 minutes, and the reaction atmosphere is flowing Ar gas. The density of the synthesized material is 97.9%. The oxidation kinetic constant at 800°C is: 7.59×10 -14 g 2 cm -4 ·s ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal expansion coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com