Protein washing agent and preparation method thereof

A cleaning agent and protein technology, applied in the field of protein cleaning agent and its preparation, can solve problems such as affecting the quality of food processing, endangering food safety, hidden dangers in food processing, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

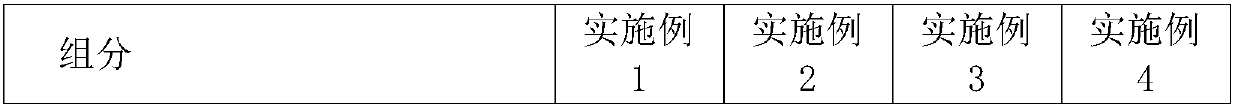

Embodiment 1

[0041] Weigh the raw materials of each component according to weight percentage, mix tea polyphenols and papain according to the mass ratio of 2:1, dissolve in disodium phosphate-citric acid buffer solution after mixing, and then successively add triethanolamine, xylene sulfonate, Add polyvinylpyrrolidone, alkylphenol polyoxyethylene ether, EDTA and deionized water into a homogeneous emulsification mixer, stir evenly for 40 minutes, adjust the pH value to 6, and obtain the product of this application.

Embodiment 2

[0043] Weigh the raw materials of each component according to weight percentage, mix tea polyphenols and papain according to the mass ratio of 2:1, dissolve in disodium phosphate-citric acid buffer solution after mixing, and then successively add triethanolamine, xylene sulfonate, Add polyvinylpyrrolidone, alkylphenol polyoxyethylene ether, EDTA and deionized water into a homogeneous emulsification mixer, stir evenly for 45 minutes, adjust the pH value to 7.5, and obtain the product of this application.

Embodiment 3

[0045] Weigh the raw materials of each component according to weight percentage, mix tea polyphenols and papain according to the mass ratio of 2:1, dissolve in disodium phosphate-citric acid buffer solution after mixing, and then successively add triethanolamine, xylene sulfonate, Add polyvinylpyrrolidone, alkylphenol polyoxyethylene ether, EDTA and deionized water into a homogeneous emulsification mixer, stir evenly for 35 minutes, adjust the pH value to 6.5, and obtain the product of this application.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com