Solar photovoltaic photo-thermal heat collector with porous foam metal heat-exchange structure

A porous metal foam and solar photovoltaic technology, which is applied in the field of solar photovoltaic photothermal heat collectors, can solve the problems of high-efficiency heat exchange, low convective heat transfer coefficient, and short heat transfer process of cooling gas, and achieve convective heat transfer effects The effect of enhancing, increasing the heat exchange area, and improving the heat exchange effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

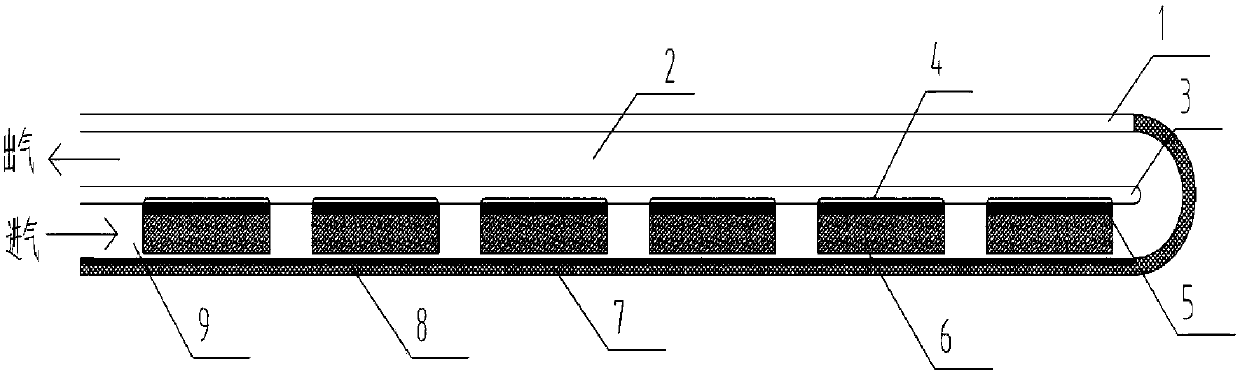

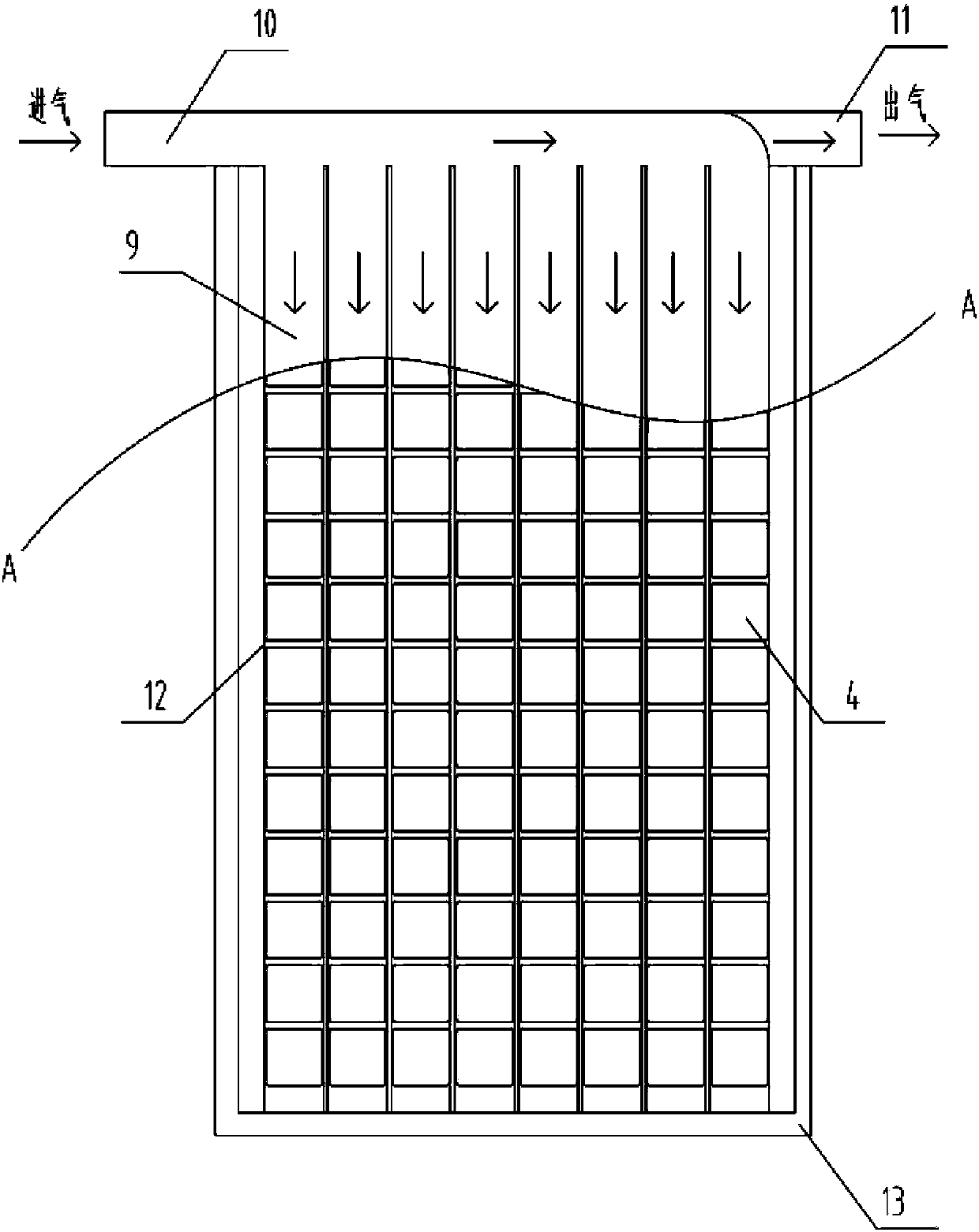

[0031] Attached below figure 1 And attached figure 2 For further elaboration:

[0032] A structural schematic diagram of a solar photovoltaic photothermal heat collector with a porous metal foam heat exchange structure, the heat collector includes a heat collection cavity 12, the side wall of the heat collection cavity 12 is a metal frame 13, and the top is a The glass cover plate 1, the bottom is an insulating layer (8), and the same side wall of the heat collecting cavity 12 is provided with a heat collector air inlet 10 and a heat collector air outlet 11; from the bottom of the heat collecting cavity 12 A thermal insulation layer 8 and a heat absorbing layer 7 are arranged in sequence upward, a metal foam layer 6 is arranged on the heat absorbing layer 7, and a thermally conductive substrate 5 and a photovoltaic cell element 4 are sequentially arranged on the upper surface of the metal foam layer 6 from bottom to top. The upper surface of the photovoltaic cell element 4 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com