Waste gas treatment equipment

A technology for waste gas treatment equipment and waste gas collection, which is used in the separation of dispersed particles, chemical instruments and methods, combined devices, etc. The effect of increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

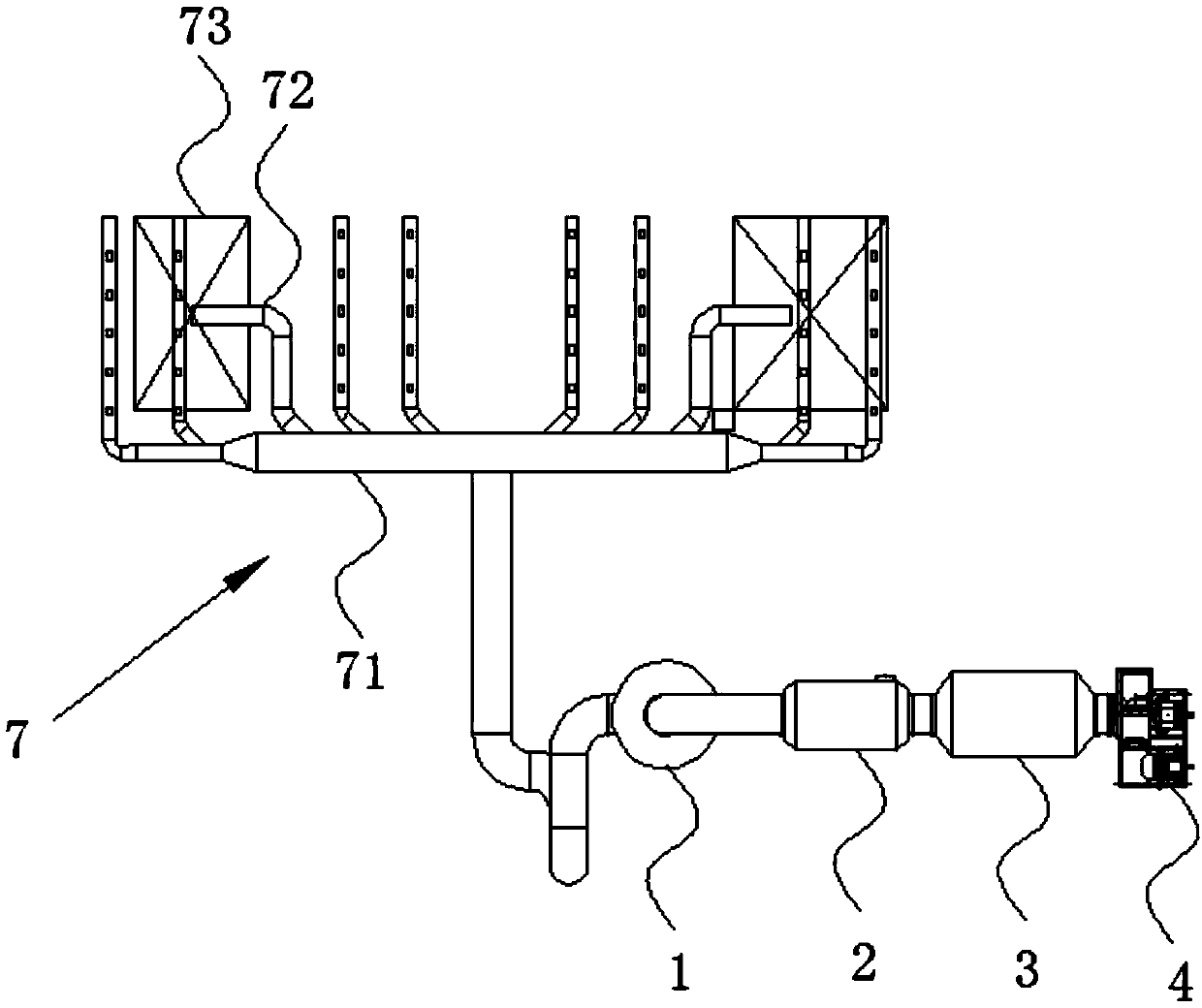

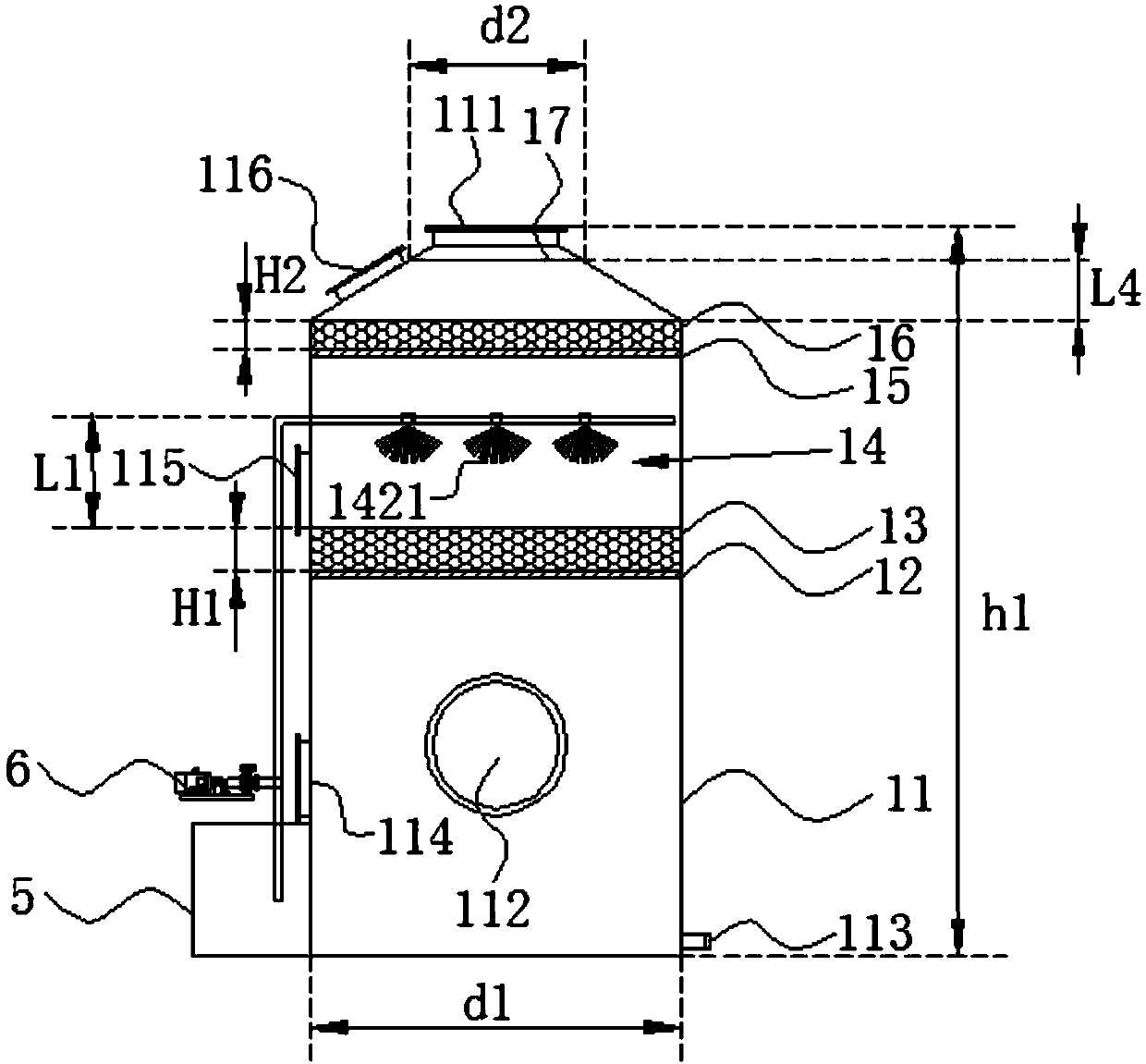

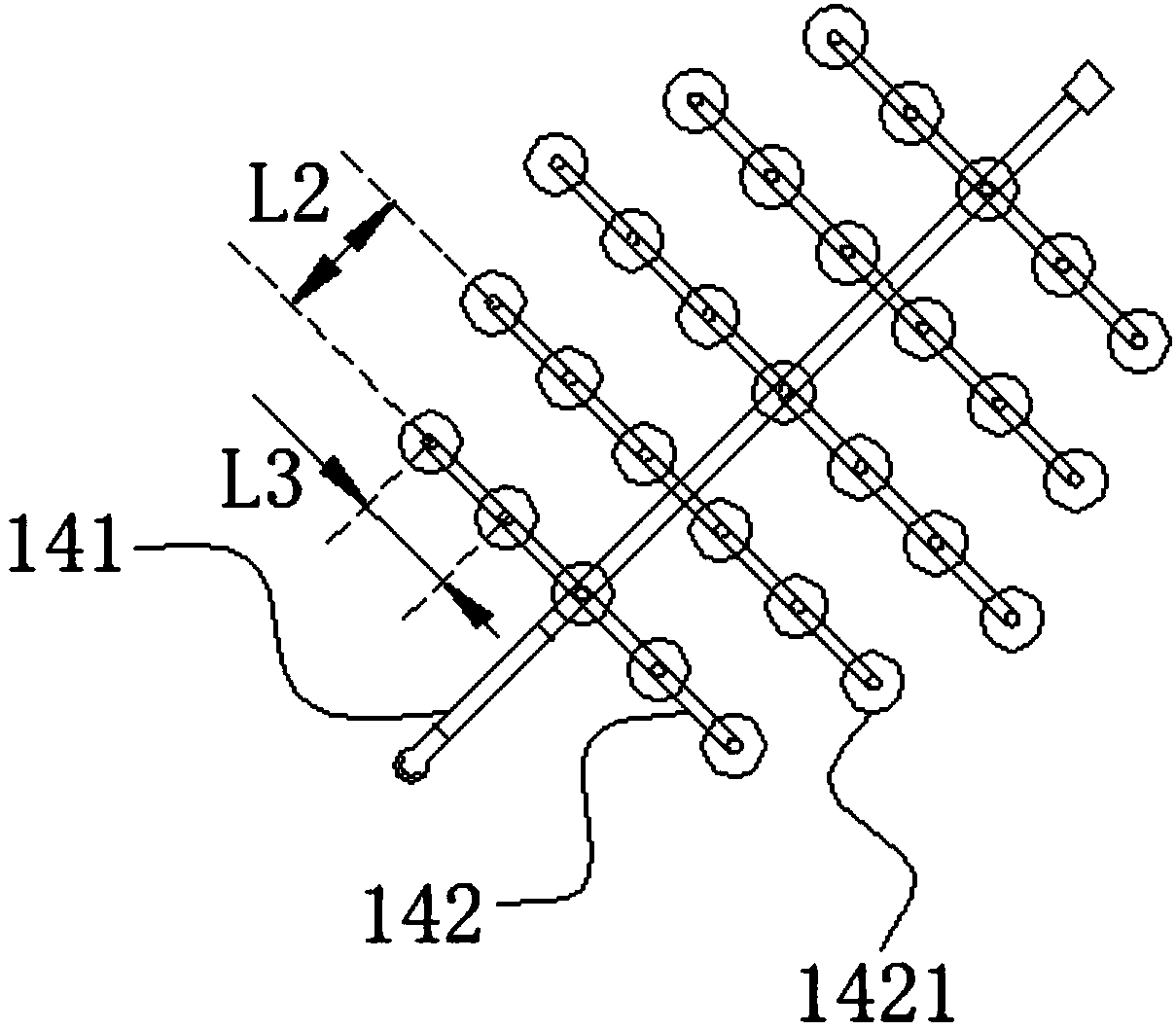

[0063] Embodiment: a kind of waste gas treatment equipment, such as Figure 1-Figure 13 As shown, it includes exhaust gas collection device 7, water washing tower 1, demister box 2, activated carbon box 3 and blower fan 4. , the demister box is located upstream of the activated carbon box, and the activated carbon box is located upstream of the fan;

[0064] The waste gas collection device includes a waste gas collection main pipe 71, a waste gas collection sub-pipe 72 and a gas collection hood 73, one end of several waste gas collection sub-pipes is provided with the gas collection hood, and the other end of several waste gas collection sub-pipes is connected to the gas collection hood. One end of the waste gas collection main pipe is connected, the other end of the waste gas collection main pipe is connected with the water washing tower, and the air inlet of each of the air collection hoods is provided with a third electric shutter;

[0065] During specific implementation, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com