Plant absorbing liquid for benzene ring VOCs and preparation method thereof

A technology of plant absorption and plant extraction liquid, which is applied in the field of plant absorption liquid of benzene ring VOCs and its preparation, can solve the problems of complex components of plant liquid, difficulty in grasping the absorption amount, and difficulty in understanding the absorption effect of VOCs, so as to improve absorption Treatment efficiency, easy operation, and the effect of reducing the amount of distillation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] A preparation method of a plant absorption liquid of benzene ring VOCs, comprising the steps of:

[0027] A. Prepare the plant extract: crush the plant extract and place it in an extraction kettle, add methanol and ethanol for extraction to obtain the plant extract;

[0028] B. Preparation of plant absorption liquid: After uniformly mixing the plant extract and emulsion, the plant absorption liquid is prepared.

[0029] Further, the plant extract in the step A is composed of the leaves of the following plants: mint, camphor tree, cinnamon tree, lemon tree, orange tree, cedar, spearmint and eucalyptus .

[0030] Further, the extraction conditions of the extraction tank in the step A are: extraction pressure 8-10 MPa, extraction temperature 45°C, carbon dioxide flow rate 22-28 L / h; extraction time 1.5-5.5 h.

[0031] Specifically, the method is as follows:

[0032] Break the plant extract into powder, put it in the extraction kettle, add a certain amount of methanol an...

Embodiment 1

[0042] A plant absorption liquid for benzene ring VOCs, including a plant extract; the plant extract includes the following components in parts by weight: 8 parts of peppermint oil, 6 parts of camphor oil, 7 parts of cinnamon oil, 6 parts of lemon oil, 3 parts pine oil, 3 parts cedar oil, 2 parts spearmint oil, and 2 parts eucalyptus oil.

Embodiment 2

[0044] A plant absorption liquid for benzene ring VOCs, including a plant extract; the plant extract includes the following components in parts by weight: 13 parts of peppermint oil, 8 parts of camphor oil, 9 parts of cinnamon oil, 8 parts of lemon oil, 6 parts pine oil, 4 parts cedar oil, 3 parts spearmint oil, and 3 parts eucalyptus oil.

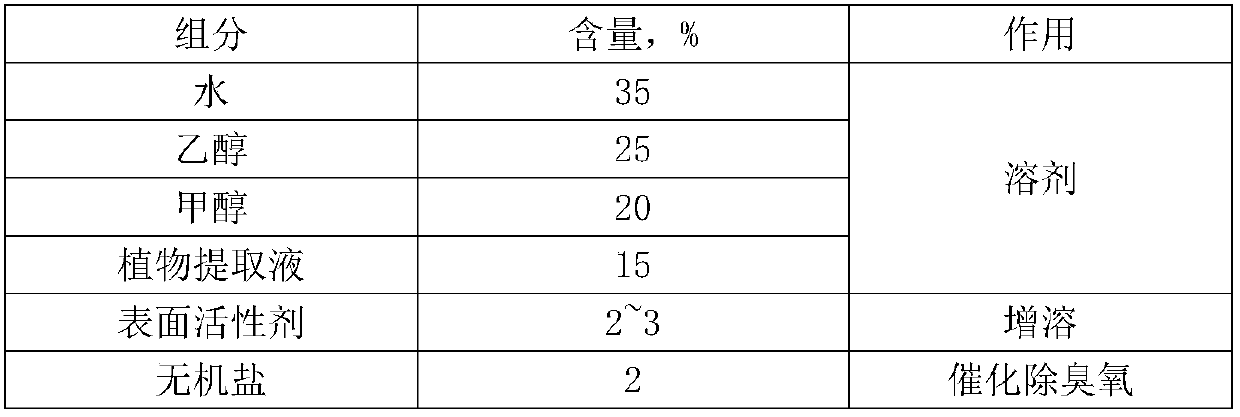

[0045] The plant absorption liquid also includes an emulsion; the weight percentages of the plant extract and the emulsion in the plant absorption liquid are 15% and 85% respectively. The emulsion comprises the following components in parts by weight: 35 parts of water, 25 parts of ethanol, 20 parts of methanol, 2 parts of Tween 20 non-ionic surfactant, and 2 parts of inorganic salt.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com