Vertical type rotational flow tower

A swirl tower, vertical technology, applied in the application field of gas purification and treatment, can solve the problems of low waste gas treatment efficiency, hidden safety hazard waste gas, complex structure, etc., and achieve the effects of easy operation, good anti-blocking performance, and good heat transfer effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments.

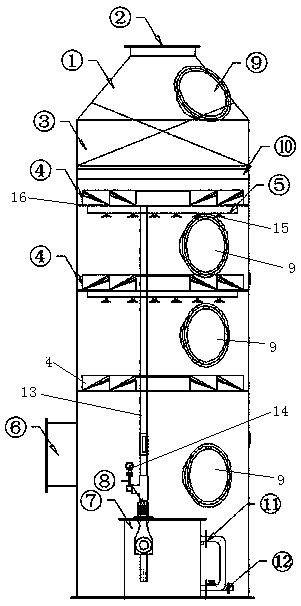

[0015] like figure 1 The shown vertical swirl tower consists of a tower body 1, several inspection windows 9 arranged on the tower body 1, and an air inlet 6 and an air outlet 2 arranged on the tower body 1 and used in conjunction with each other. And the water supply assembly arranged in the tower body 1, and the spray assembly arranged in the tower body 1 and used in conjunction with the water supply assembly; the water supply assembly includes the water tank 7 arranged at the bottom of the tower body 1, and the The automatic water replenishment port 11 and the sewage outlet 12 used in conjunction with the 7 side, the water pump 8 arranged on the water tank 7, the water guide pipe 13 connected to the water pump 8, and several spray pipes connected with the water guide pipe 13 5, and several spray heads 15 arranged on the spray pipe 5, and se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dust removal efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com