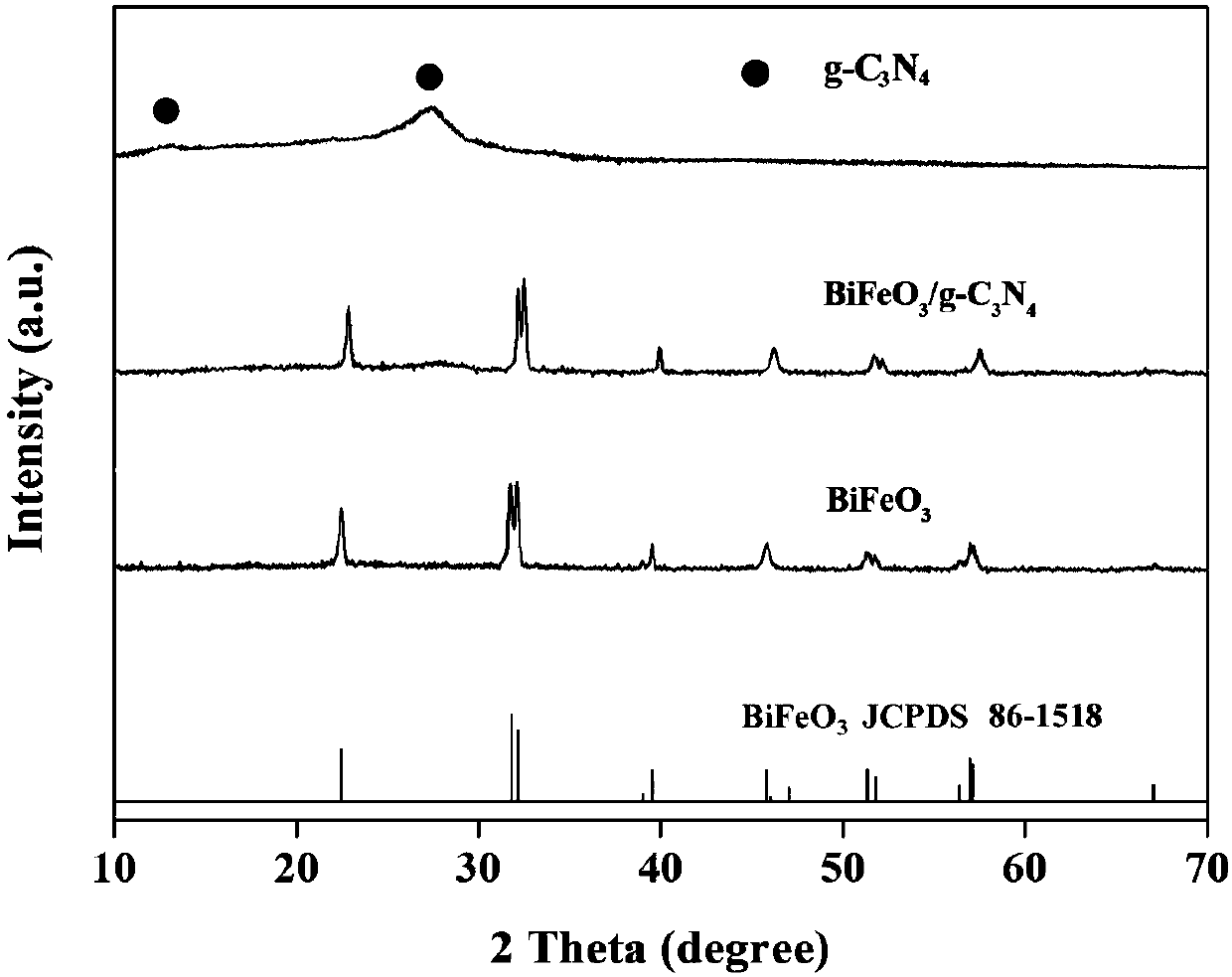

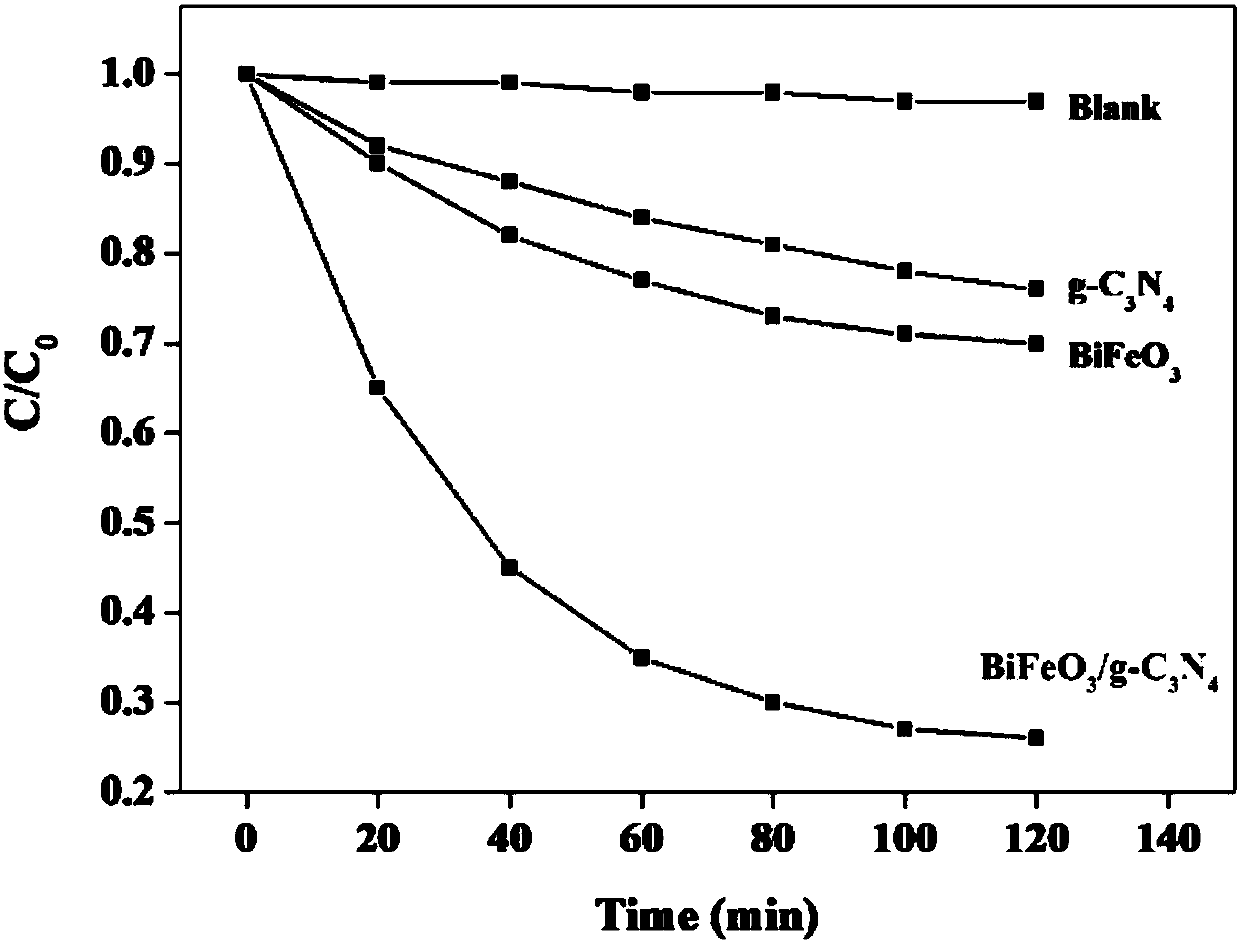

Method for preparing BiFeO3/g-C3N4 heterojunction photocatalyst

A photocatalyst and heterojunction technology, applied in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0012] (1) Weigh 3 g of melamine powder into an alumina crucible and cover it, heat it to 550° C. in a muffle furnace, and keep it at this temperature for 4 hours. After natural cooling, the pale yellow powder was collected and ground for use.

[0013] (2) Weigh 4.850g bismuth nitrate pentahydrate (Bi(NO 3 ) 3 ·5H 2 O) and 2.704g ferric chloride (FeCl 3 ·6H 2 O) Dissolve in 100 mL of acetone solution and sonicate for 30 minutes.

[0014] (3) Add 300mL deionized water and continue to stir, then add concentrated ammonia water to make the pH value about 11. The precipitate was collected and washed several times by centrifugation with deionized water until the pH value was neutral.

[0015] (4) Disperse the precipitate in deionized water, add 15 g of NaOH solution and continue stirring for 30 minutes. The prepared solution was poured into a 100mL Teflon-lined stainless steel high-temperature reaction kettle, heated to 180°C and kept for 72 hours.

[0016] (5) After natural...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com