Semi-continuous fine grain high-temperature master alloy casting process

A high-temperature master alloy and casting process technology, applied in the field of metal materials, can solve problems such as coarse grains and poor surface quality, and achieve the effect of smooth surface, low cost and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

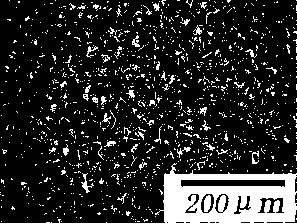

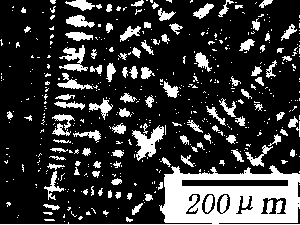

Image

Examples

Embodiment 1

[0034] Step 1: Melting K418 high-temperature master alloy in a 1000KG vacuum induction furnace, the melting point of K418 is 1320°C, the controlled refining temperature is 1580°C, the casting temperature is 1460°C, and the superheat is 140°C;

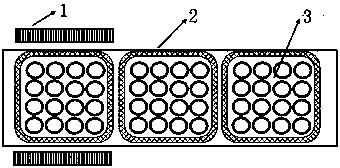

[0035] Step 2: Place multiple sets of metal or ceramic modules 3 on the mobile trolley, place the mobile trolley 2 between the parallel electromagnetic stirrers 1, move the modules to the middle of the electromagnetic stirrer 1 through the mobile trolley 2, and place the modules at the bottom The use of thermal insulation materials prevents heat loss and rapid temperature drop;

[0036] Step 3: Cast the high-temperature master alloy obtained in Step 1 into a mold set, the baking temperature of the metal mold set is 400°C, and start the electromagnetic stirring system;

[0037] Step 4, stir with the electromagnetic stirrer 1 according to the set stirring process parameters, the stirring parameters are: stirring current 400A, stirring fre...

Embodiment 2

[0040] Step 1: Melting K213 high-temperature master alloy in a 500KG vacuum induction furnace, the melting point of K213 is 1340°C, the controlled refining temperature is 1600°C, the casting temperature is 1480°C, and the superheat is 150°C;

[0041] Step 2: Place multiple sets of metal or ceramic modules 3 on the mobile trolley, place the mobile trolley 2 between the parallel electromagnetic stirrers 1, move the modules to the middle of the electromagnetic stirrer 1 through the mobile trolley 2, and place the modules at the bottom The use of thermal insulation materials prevents heat loss and rapid temperature drop;

[0042] Step 3: Cast the high-temperature master alloy obtained in Step 1 into a mold set, the baking temperature of the metal mold set is 650°C, and start the electromagnetic stirring system;

[0043] Step 4: Stir with the electromagnetic stirrer 1 according to the set stirring process parameters, the stirring parameters are: stirring current 250A, stirring freq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com