Single-tube multi-pole safe sliding line type combined coding alignment method of unloading trolleys

A technology of unloading trolley and multi-pole, which is applied in the directions of loading/unloading, conveyors, mechanical conveyors, etc., which can solve the problems of wheel slip accumulation error, magnetic dust interference malfunction, and high engineering cost, so as to reduce the frequency of feeding and save Operating costs and the effect of reducing construction investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] specific implementation plan

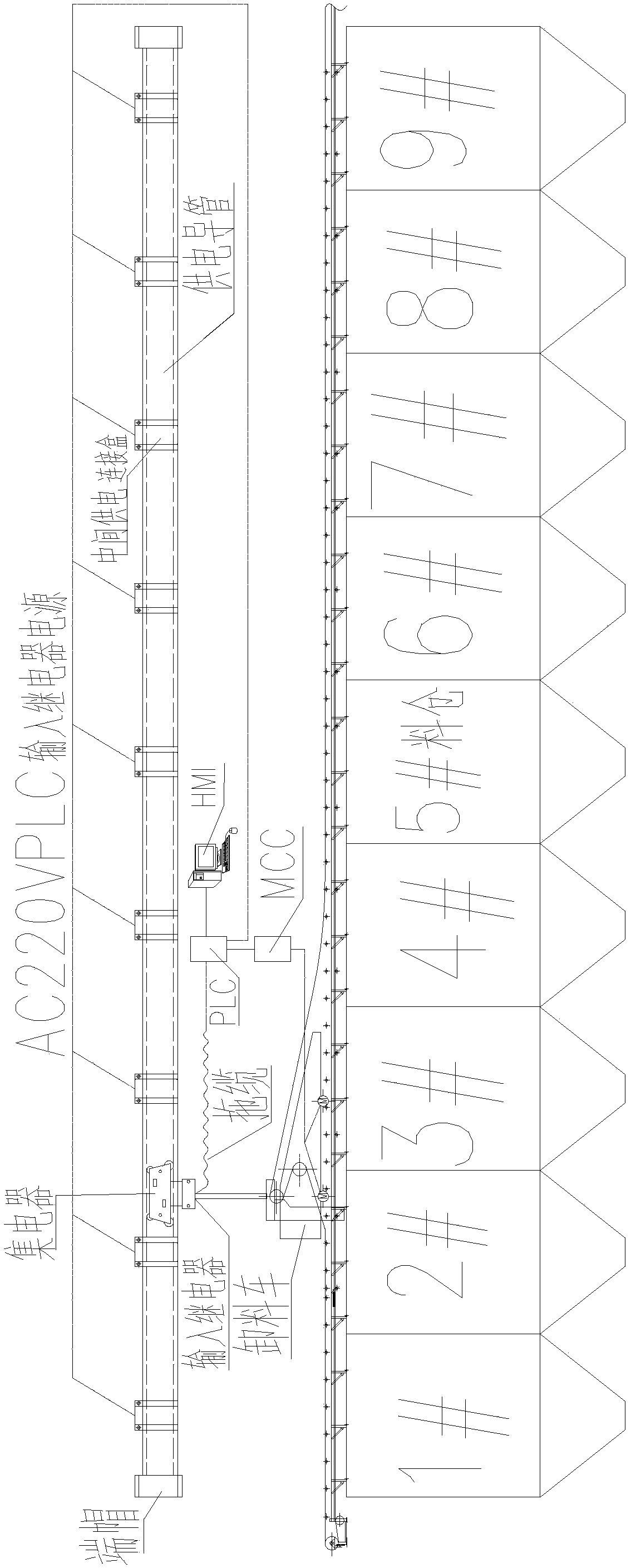

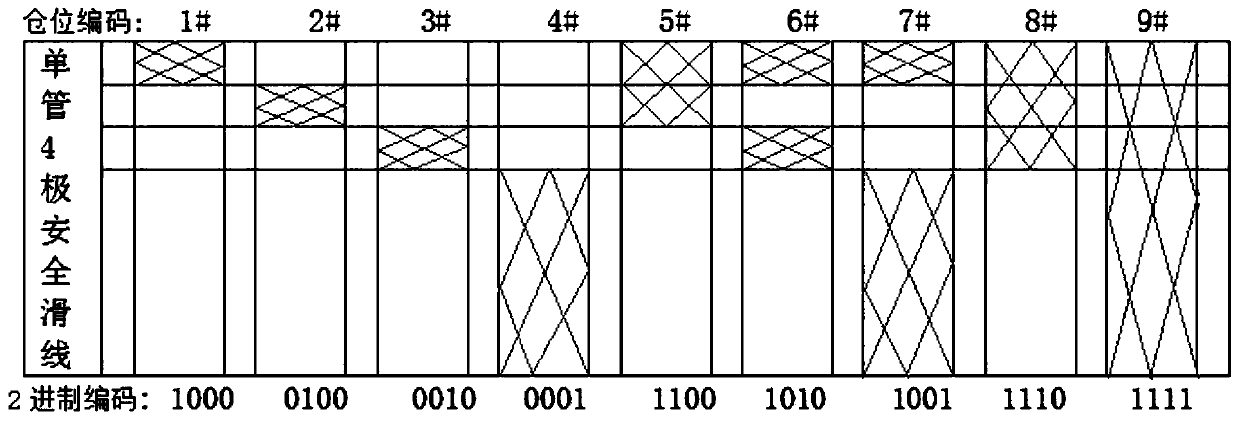

[0010] like figure 1 As shown, the special single-tube multi-pole small-capacity multi-pole safety sliding contact line for transformation is installed on the side of the belt bracket of the silo, according to figure 2 As shown in the silo that needs to be parked and unloaded in different intervals, it is necessary to set up a copper bar section, and another example figure 1 As shown, an intermediate power supply connection box is set in the middle of the slide line of each silo, and the AC220VPLC input relay power is supplied to the copper bar section set for it through the intermediate power supply connection box of each silo; The electrical signal of the section of the copper bar is led to the input relay of the programmable logic controller PLC, and then the DC24 node is connected to the programmable logic controller PLC. In this way, the PLC accepts different binary code arrangements to judge the specific condition of the heavy unlo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com