Preparation method of transition metal fluoride-doped composite hydrogen storage material, and application thereof in hydrogen storage material

A hydrogen storage material and transition metal technology, applied in non-metallic elements, hydrogen, inorganic chemistry, etc., can solve the problem of high initial hydrogen desorption temperature, and achieve the effects of low cost, easy mass production and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

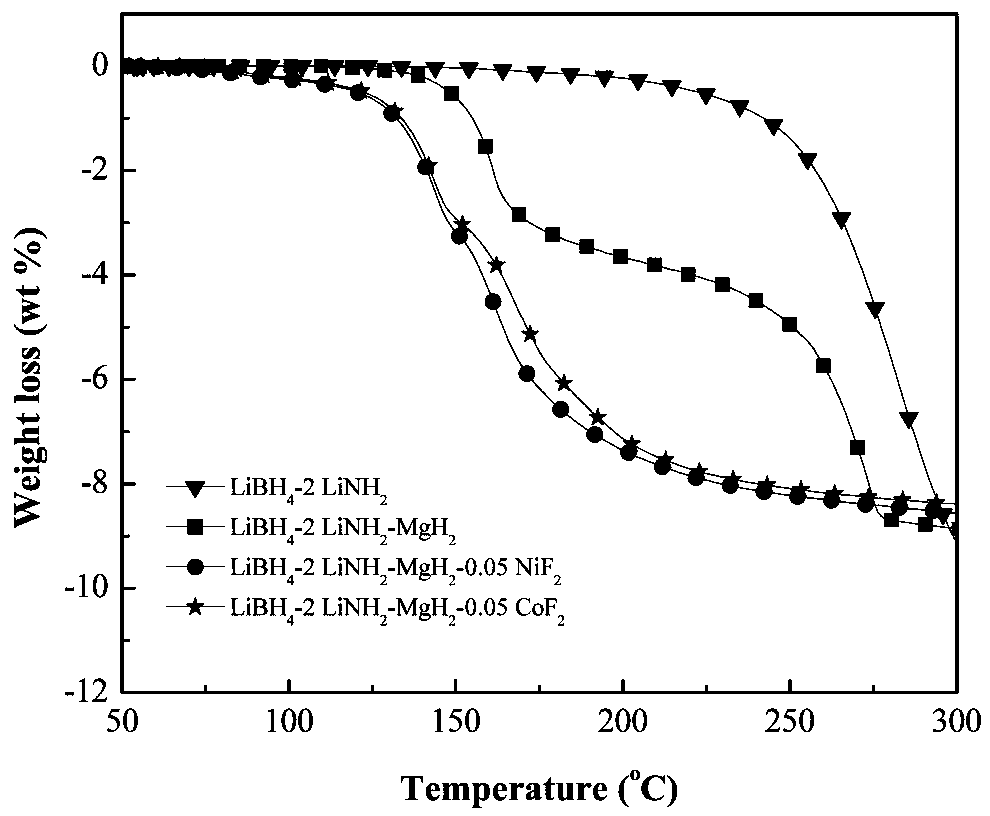

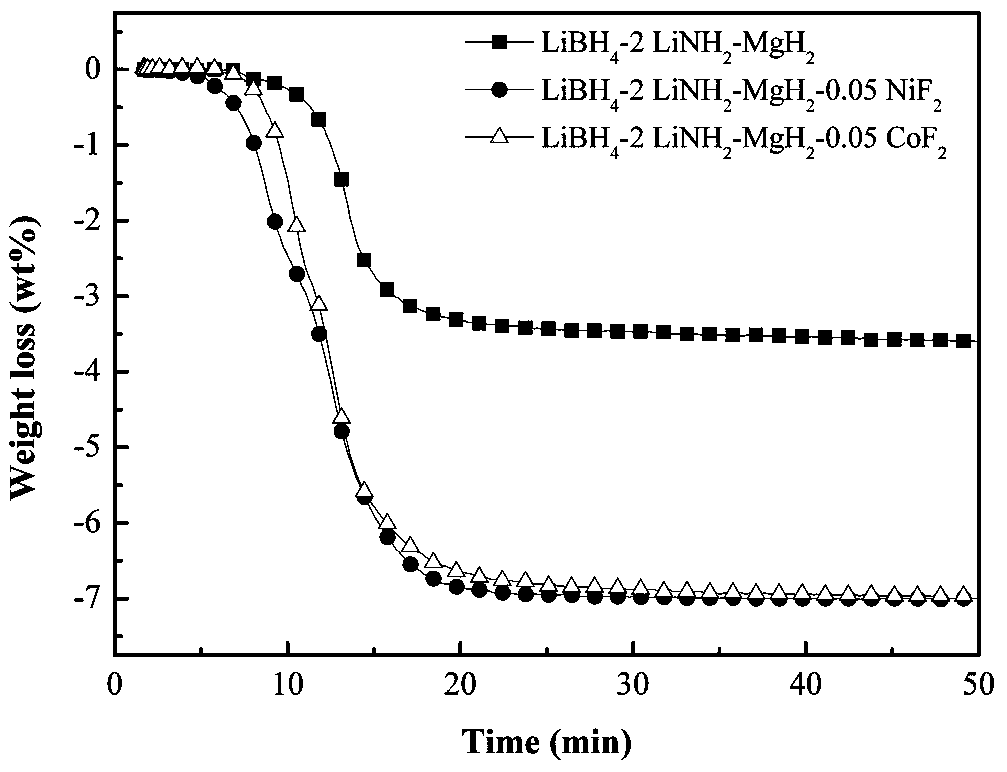

[0026] A transition metal fluoride-doped composite hydrogen storage material, LiBH 4 -2LiNH 2 -MgH 2 -0.05NiF 2 A method for preparing a hydrogen storage material, comprising the following steps:

[0027] Step 1) Weighing of raw materials: under the protection of argon, weigh 0.088 g LiBH 4 , 0.1856 g LiNH 2 , 0.1064 gMgH 2 and 0.02 g NiF 2 Powder, 0.4 g in total;

[0028] Step 2) Preparation of composite hydrogen storage materials by ball milling: under the protection of argon, put the balls and the raw materials weighed in step 1) into a ball mill jar and seal it; then put the ball mill jar into the ball mill, set the ball milling speed to 200 rpm, and the ball milling time to 2 h to obtain LiBH 4 -2LiNH 2 -MgH 2 -0.05NiF 2 Hydrogen storage material.

Embodiment 2

[0030] A transition metal fluoride-doped composite hydrogen storage material, LiBH 4 -2LiNH 2 -MgH 2 -0.05CoF 2 A method for preparing a hydrogen storage material, comprising the following steps:

[0031] Step 1) Weighing of raw materials: under the protection of argon, weigh 0.088 g LiBH 4 , 0.1856 g LiNH 2 , 0.1064 gMgH 2 and 0.02 g CoF 2 Powder, 0.4 g in total;

[0032] Step 2) Preparation of composite hydrogen storage materials by ball milling: under the protection of argon, put the balls and the raw materials weighed in step 1) into a ball mill jar and seal it; then put the ball mill jar into the ball mill, set the ball milling speed to 200 rpm, and the ball milling time to 2 h to obtain LiBH 4 -2LiNH 2 -MgH 2 -0.05CoF 2 Hydrogen storage material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com