A kind of formula and preparation method of retarder for magnesite cementitious material

A technology of cementitious materials and retarders, applied in the field of retarders, can solve the problems of deformation and cracking of heat dispersing products, insufficient strength of magnesite products, unfavorable molding operations, etc., achieve excellent retardation effect and strength, and enhance retardation. effect, the effect of slowing down the dissipation of heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] (1) Weigh 25 parts of DMF, 3 parts of polysuccinimide, 2 parts of glacial acetic acid, 0.5 part of sodium citrate, 0.5 part of humic acid, 0.5 part of ferric chloride, 7 parts of zinc 4-hydroxybenzenesulfonate, 0.1 part of sodium hydroxymethyl cellulose, 45 parts of water for later use;

[0022] (2) Mix and stir the polysuccinimide and DMF in step (1) at a temperature of 90°C until the polysuccinimide is completely dissolved, then slowly add the glacial acetic acid in step (1) , after mixing and stirring for 60 minutes, a polysuccinimide solution was obtained;

[0023] (3) Sodium citrate, humic acid, ferric chloride, 4-hydroxybenzenesulfonate zinc and water are mixed in step (1) to obtain a mixture aqueous solution, and the mixed aqueous solution is warmed up to 50° C. Wherein slowly add the hydroxymethyl cellulose sodium that takes by weighing in the step (1), stir 20 minutes, solution becomes uniform viscous liquid;

[0024] (4) Mix the polysuccinimide solution obta...

Embodiment 2

[0026] Weigh 35 parts of DMF, 7 parts of polysuccinimide, 6 parts of glacial acetic acid, 1.2 parts of sodium citrate, 1.2 parts of humic acid, 1.2 parts of ferric chloride, 12 parts of 4-hydroxybenzenesulfonic acid zinc salt, hydroxymethyl 0.5 part of sodium cellulose, 50 parts of water for subsequent use, and other steps are the same as in Example 1.

Embodiment 3

[0028] Weigh 30 parts of DMF, 5 parts of polysuccinimide, 4 parts of glacial acetic acid, 1 part of sodium citrate, 1 part of humic acid, 1 part of ferric chloride, 10 parts of 4-hydroxybenzenesulfonic acid zinc salt, hydroxymethyl 0.2 part of sodium cellulose, 48.8 parts of water for subsequent use, and other steps are the same as in Example 1.

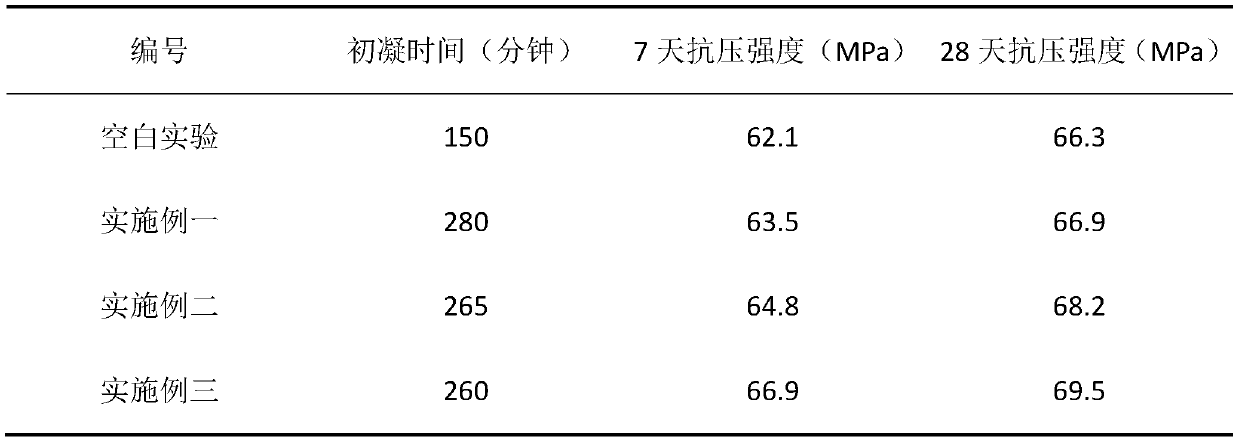

[0029] The experimental data of the retarding effect of embodiment one, embodiment two and embodiment three and intensity are as shown in table 1:

[0030] Table 1 embodiment one, embodiment two and embodiment three experimental data

[0031]

[0032] It can be seen from the data in Table 1 that the retarders of Example 1, Example 2 and Example 3 all have good retarding effects when applied to Lingmei gel materials, and also have excellent strength properties, among which The setting retarding effect and strength performance of embodiment three are the best.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com