High-strength aging-resistant acrylic material

An aging acrylic, high-strength technology, used in chemical instruments and methods, layered products, glass/slag layered products, etc. Resin use and other problems, to achieve the effect of not easy to break, good mechanical strength, light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

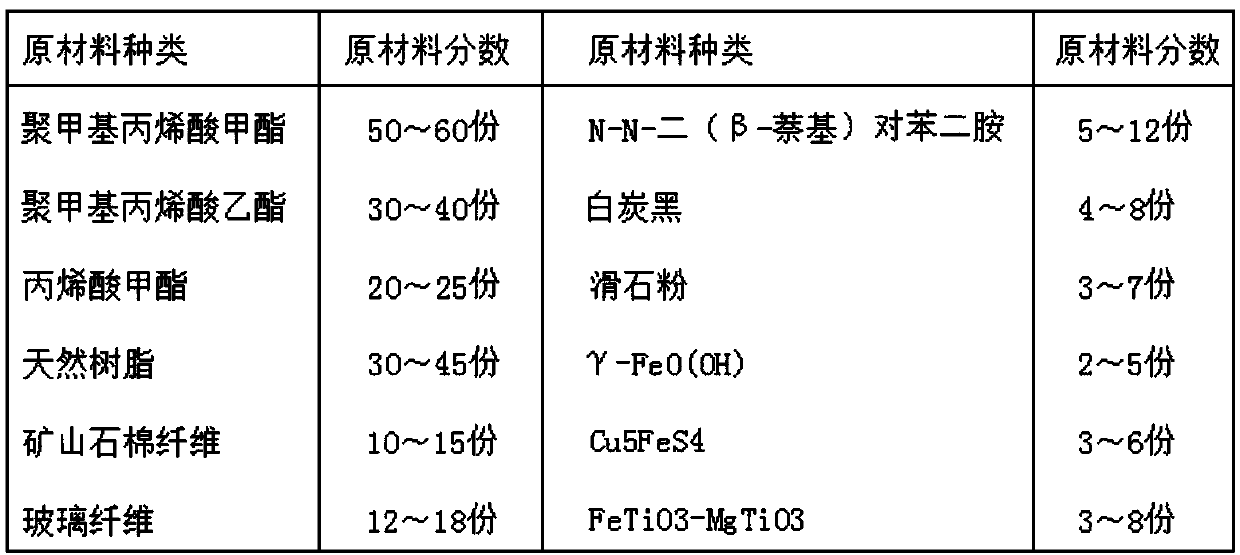

[0022] see Figure 1-2 As shown, the technical solution adopted in the present invention is: a high-strength anti-aging acrylic material, the high-strength anti-aging acrylic material includes 65 parts of polymethyl methacrylate, 40 parts of polyethyl methacrylate, methyl acrylate 25 parts of ester, 45 parts of natural resin, 15 parts of mine asbestos fiber, 18 parts of glass fiber, 12 parts of N-N`-di(β-naphthyl)-p-phenylenediamine, 8 parts of white carbon black, 7 parts of talcum powder, γ- 5 parts of FeO(OH), Cu 5 FeS 4 6 parts and FeTiO 3 -MgTiO 3 8 servings.

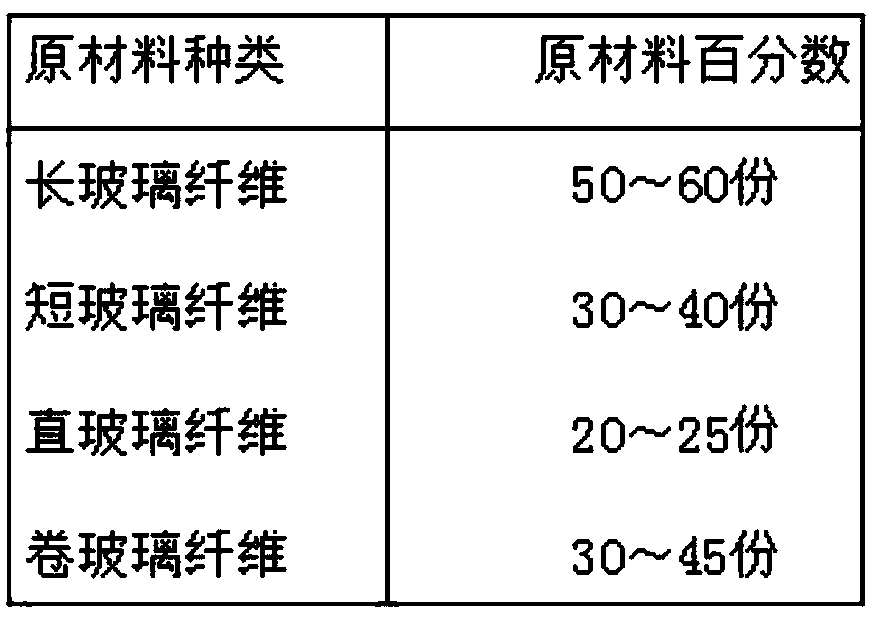

[0023] Wherein, the glass fibers include 25% long glass fibers, 25% short glass fibers, 25% straight glass fibers and 25% rolled glass fibers.

[0024] Wherein, the manufacturing method of the high-strength anti-aging acrylic material comprises the following steps:

[0025] 1). Primary melting: crush 60% of mine asbestos fiber and glass fiber and mix with γ-FeO(OH), Cu 5 FeS 4 and FeTiO 3 -MgTiO 3 After mi...

Embodiment 2

[0031] see Figure 1-2 As shown, the technical solution adopted in the present invention is: a high-strength anti-aging acrylic material, the high-strength anti-aging acrylic material includes 50 parts of polymethyl methacrylate, 30 parts of polyethyl methacrylate, methyl acrylate 20 parts of ester, 30 parts of natural resin, 10 parts of mine asbestos fiber, 12 parts of glass fiber, 5 parts of N-N`-di(β-naphthyl)-p-phenylenediamine, 4 parts of white carbon black, 3 parts of talcum powder, γ- 2 parts of FeO(OH), Cu 5 FeS 4 3 parts and FeTiO 3 -MgTiO 3 3 copies.

[0032] Wherein, the glass fibers include 27% long glass fibers, 23% short glass fibers, 25% straight glass fibers and 25% rolled glass fibers.

[0033] Wherein, the manufacturing method of the high-strength anti-aging acrylic material comprises the following steps:

[0034] 1). Primary melting: crush 40% of mine asbestos fiber and glass fiber and mix with γ-FeO(OH), Cu 5 FeS 4 and FeTiO 3 -MgTiO 3 After mixin...

Embodiment 3

[0040] see Figure 1-2 As shown, the technical solution adopted in the present invention is: a high-strength anti-aging acrylic material, the high-strength anti-aging acrylic material includes 60 parts of polymethyl methacrylate, 35 parts of polyethyl methacrylate, methyl acrylate 22 parts of ester, 40 parts of natural resin, 15 parts of mine asbestos fiber, 15 parts of glass fiber, 6 parts of N-N`-di(β-naphthyl)-p-phenylenediamine, 6 parts of white carbon black, 6 parts of talcum powder, γ- 3 parts of FeO(OH), Cu 5 FeS 4 4 parts and FeTiO 3 -MgTiO 3 5 servings.

[0041] Wherein, the glass fibers include 27% of long glass fibers, 35% of short glass fibers, 22% of straight glass fibers and 16% of rolled glass fibers.

[0042] Wherein, the manufacturing method of the high-strength anti-aging acrylic material comprises the following steps:

[0043] 1). Primary melting: crush 50% of mine asbestos fiber and glass fiber and mix with γ-FeO(OH), Cu 5 FeS 4 and FeTiO 3 -MgTiO ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com