Micro-droplet control method based on laser direct writing technology

A laser direct writing, micro droplet technology, applied in nanotechnology, laser welding equipment, devices for coating liquid on surfaces, etc., can solve the problems of low resolution and poor flexibility, and achieve high resolution and low production cost. , The method is simple and controllable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

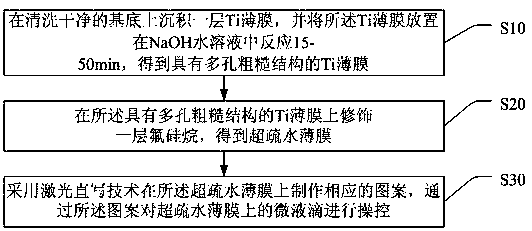

Method used

Image

Examples

Embodiment 1

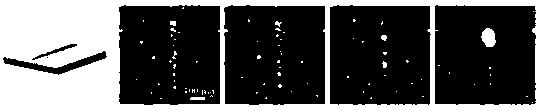

[0042] Anisotropic patterns are designed by laser direct writing technology to drive micro-droplets in a directional way:

[0043] 1. Deposit a 100 nm-thick Ti film on a cleaned substrate by magnetron sputtering, and then react the Ti film in a 10 M sodium hydroxide solution at 60 °C for 30 minutes to obtain a Ti film with a porous rough structure. Film; A layer of fluorosilane was modified by chemical vapor deposition on the surface of a Ti film with a porous rough structure at 120°C for 4 hours to obtain a super-hydrophobic film;

[0044] 2. Use laser direct writing technology to directly write anisotropic patterns point by point on the super-hydrophobic film. During the laser sintering process, the roughness of the super-hydrophobic surface is reduced, thereby changing the wettability of the processed part;

[0045]3. Spraying water mist on the patterned film, since the micro-droplets are affected by the surface energy gradient and the Laplace pressure on the anisotropic pa...

Embodiment 2

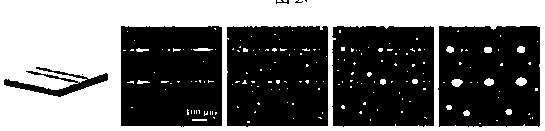

[0048] Directional driving of micro-droplets by processing wettability patterns of different shapes on superhydrophobic substrates by laser direct writing technology

[0049] 1. Deposit a 100 nm thick Ti film on a cleaned substrate by magnetron sputtering, and then react the Ti film in a 10 M sodium hydroxide solution at 60 °C for 30 minutes to obtain a Ti film with a porous rough structure. Film; A layer of fluorosilane was modified by chemical vapor deposition on the surface of a Ti film with a porous rough structure at 120°C for 4 hours to obtain a super-hydrophobic film;

[0050] 2. Use laser direct writing technology to design a circle, b oval, c trapezoid, d pentagon, e hexagon, f rectangle, g triangle, h missing corner, i plaque on the surface of the super-hydrophobic film , j pentagonal droplet array and k elliptical droplet array pattern, in the laser sintering process, can change the wettability of the processed part (that is, the pattern part), the surface energy of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com