Infinite-endurance air power system and engine system thereof

An aviation aerodynamic and air compressor technology, which is applied to machines/engines, pressure vessels, mechanical equipment, etc., and can solve the problems of weak driving force and inability to achieve infinite battery life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

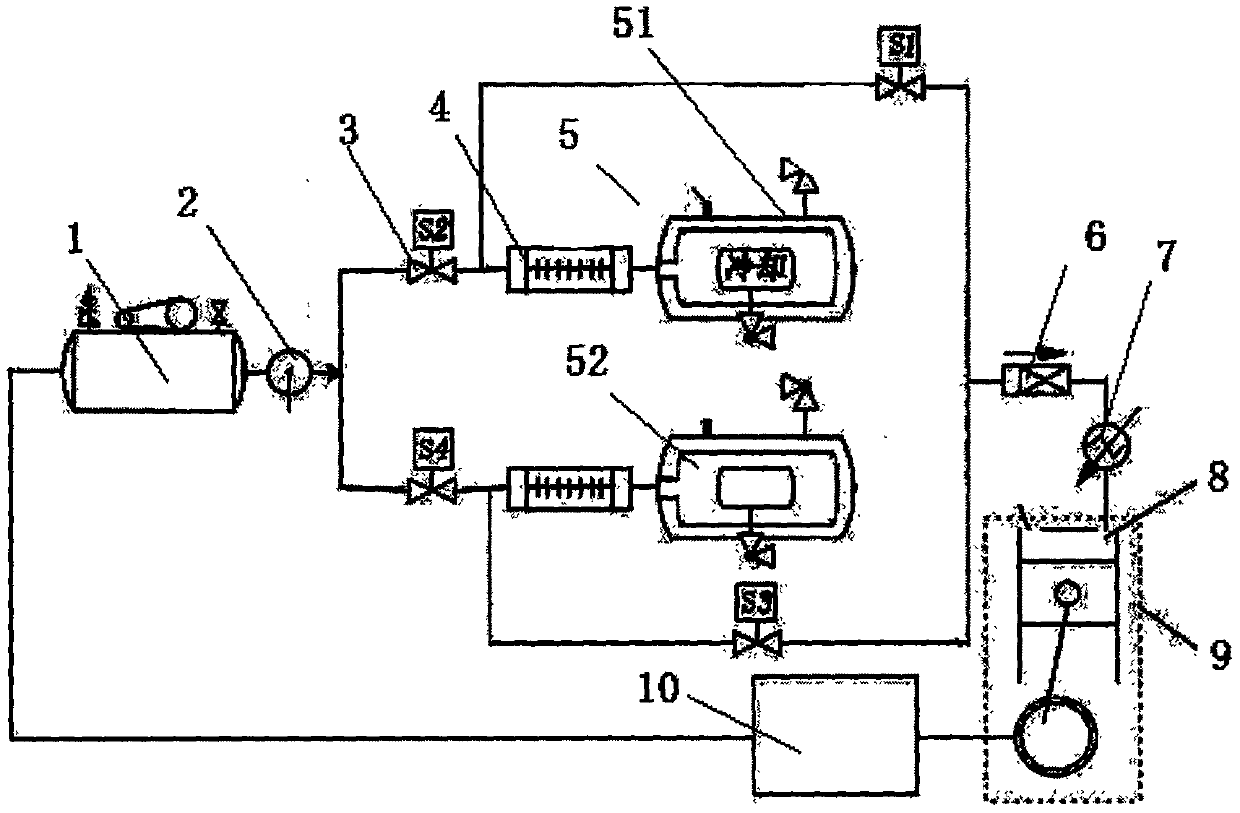

[0031] A kind of infinite cruising aerodynamic system of the present invention, see figure 1 As shown, it includes a miniature air compressor 1 and a plurality of air storage tanks 5, and the present embodiment is 2 air storage tanks 5, which are connected with the air compressor 1 through the air intake pipeline assembly, and through the electromagnetic valve on the air intake pipeline, Two air storage tanks 5 are controlled to inflate alternately, the air storage tanks 5 are connected to the air outlet pipeline assembly, and the two air storage tanks are controlled to supply air alternately through the electromagnetic valve on the air outlet pipeline.

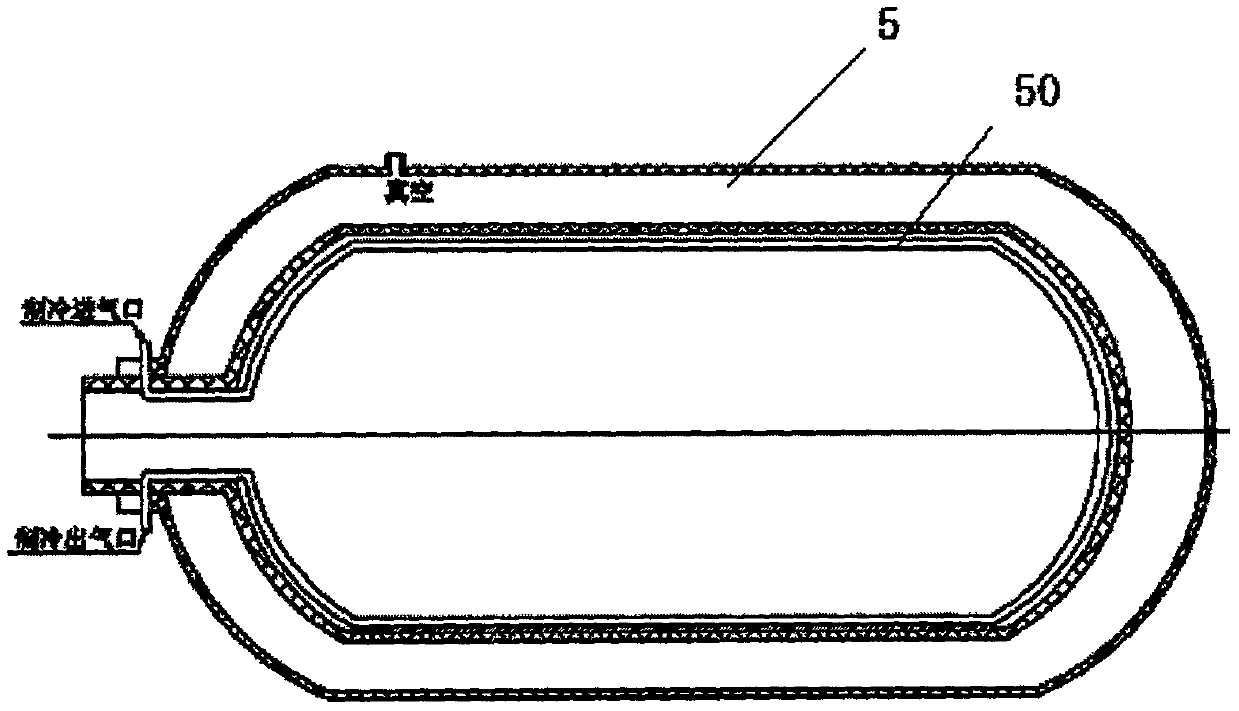

[0032] As preferably, a refrigeration heat exchange device 50 is provided on the inner wall of the air storage tank 5, which reduces the temperature of the inner tank, increases the accumulation of air molecules per unit volume, and improves the gas storage capacity of the air; further, in the intake air A heat exchanger 4 is...

Embodiment 2

[0041] see Figure 4 As shown, the piston used in the air compressor includes a piston body 13 and a piston ring. The piston body is composed of a piston head 16, a piston skirt 11 and a piston pin hole 12. The piston head 16 is provided with an upper gas ring groove 18 and a lower ring groove. The gas ring groove 19, the piston ring includes an upper piston ring and a lower piston ring, the piston skirt 11 is covered with a wear-resistant self-lubricating sheet 14, and the upper end surface of the upper gas ring groove 18 is provided with a ring around the upper gas ring groove 18. Planar air holes 17 are arranged, and the inner wall of the lower gas ring groove 19 is provided with vertical air holes 15 around the inner wall.

Embodiment 3

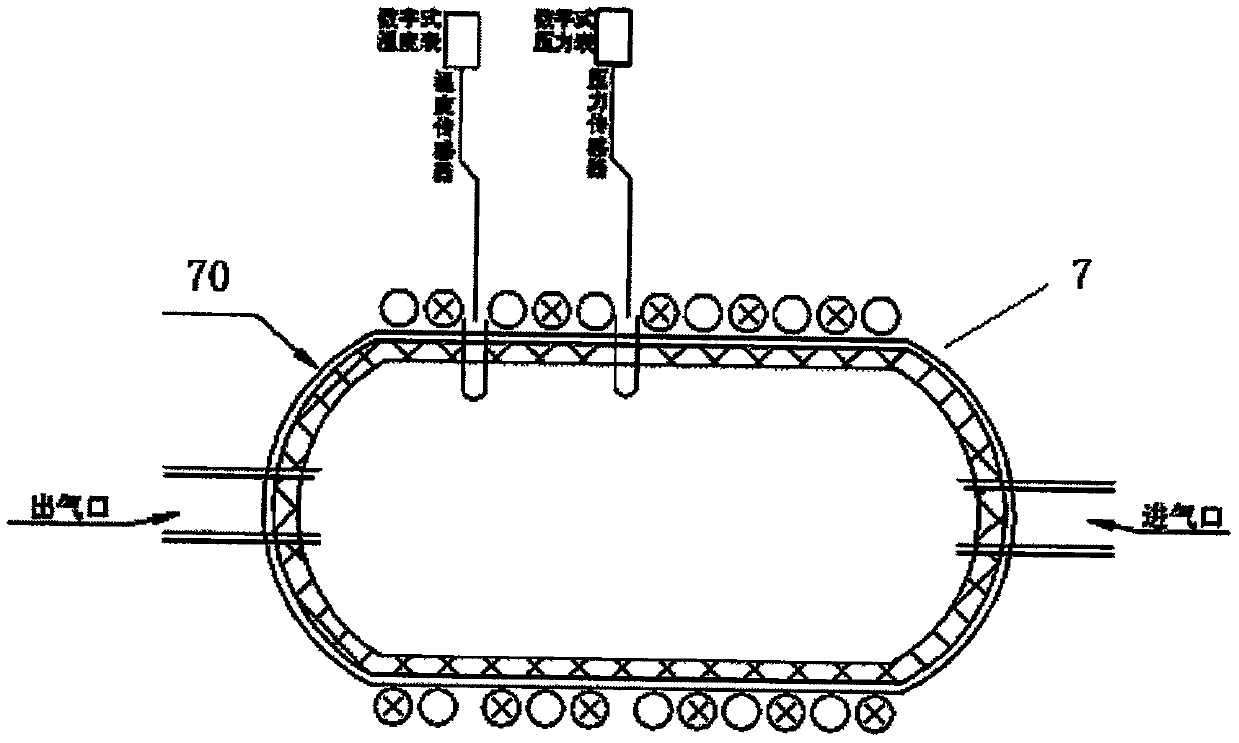

[0043] The present invention also provides an infinite-endurance aerodynamic engine system, including the above-mentioned infinite-endurance aerodynamic system providing aerodynamic force, air entering the aerodynamic engine, and the engine providing power for the transmission system 10 for the air compressor 1 to generate motion.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com