Food tracking method based on material input

A food traceability and material technology, which is applied in the field of food traceability based on material input, can solve the problems of complicated input procedures, difficult traceability, and long investigation cycle, and achieve the effect of reducing traceability workload, shortening workload, and high traceability efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

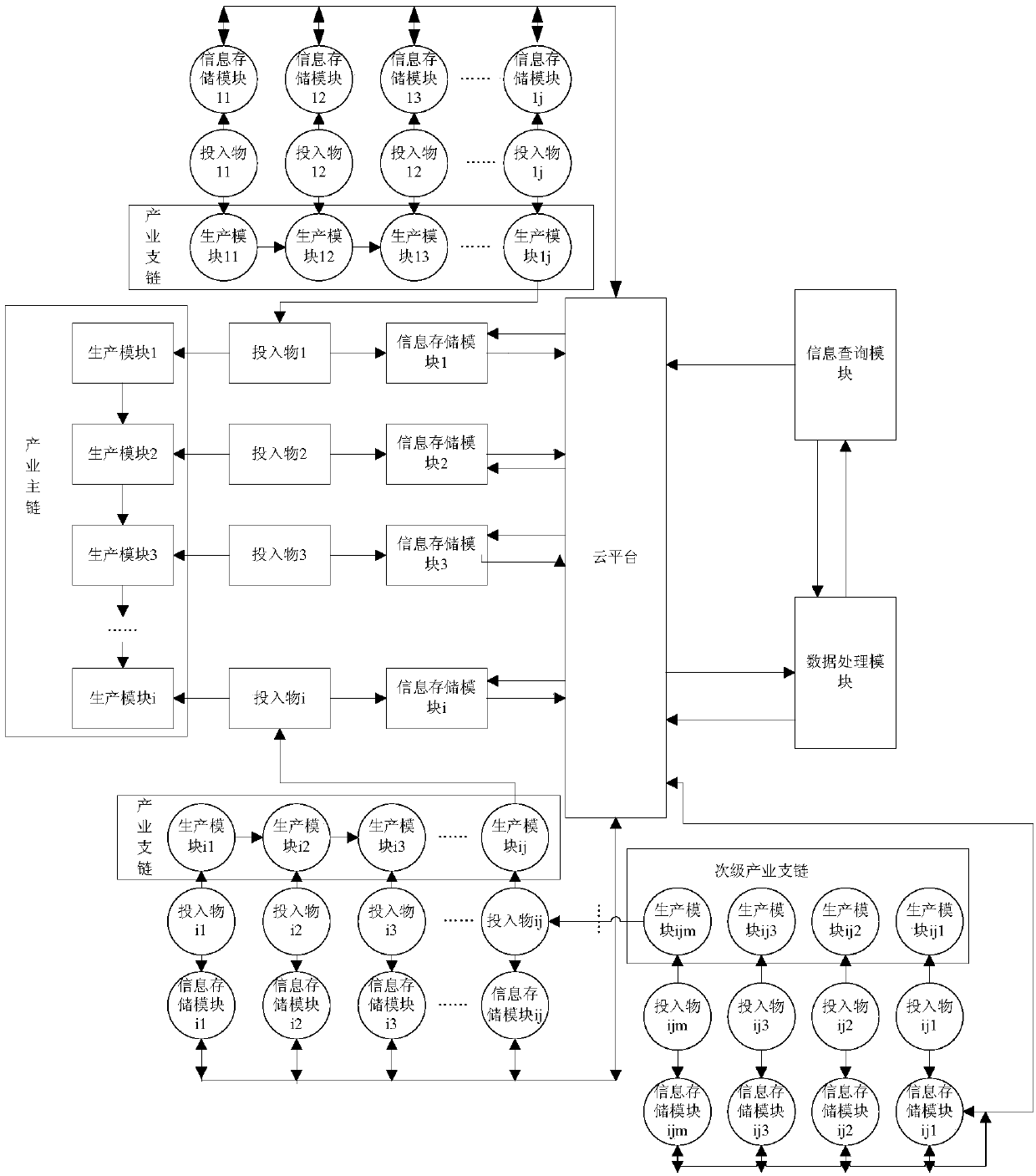

[0032] Food traceability methods based on material input, such as figure 1 As shown, it includes the main industrial chain of food production from the source to the consumption terminal, the industrial branch chain from the source to the input where the input is located, the information storage module, the information query module, the cloud platform, and the data processing module;

[0033] The industrial main chain is divided into multiple production modules i according to the food production process, and corresponding to each production module i, the information of input i is entered into the information storage module i;

[0034]The industrial branch chain from the source to the input i where the input i is located is divided into multiple production modules j according to the production process, and the relevant information of the input ij corresponding to each production module j is stored in the information storage module ij;

[0035] The industrial branch chain from th...

Embodiment 2

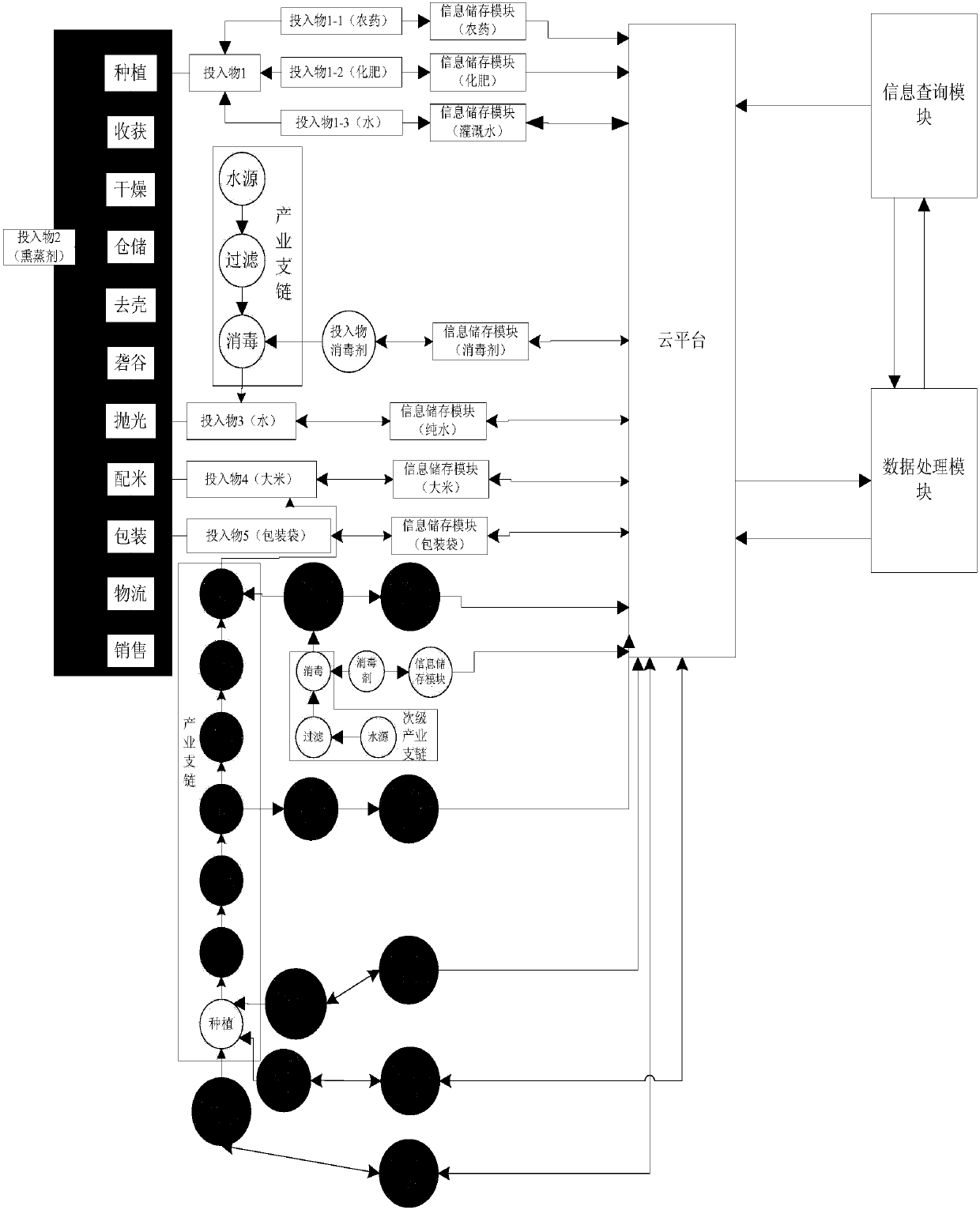

[0044] The application of a food traceability method based on material input in rice figure 2 shown.

[0045] Including the main industrial chain of rice from planting to consumption terminal, which in turn includes the industrial main chain formed by planting, harvesting, drying, storage, husking, hulling, polishing, rice blending, packaging, logistics, sales and other links; Water treatment industry branch chain formed by water source, filtration and disinfection; information storage module, information query module, cloud platform and data processing module for storing various inputs.

[0046] The industrial main chain is divided into multiple production modules i according to the food production process, which are planting, harvesting, drying, storage, husking, hulling, polishing, rice blending, packaging, logistics, and sales. There are 3 modules corresponding to the planting modules. Inputs are pesticides, fertilizers, and irrigation water; the input corresponding to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com