Plant cultivation box

An incubator and plant technology, applied in the field of plant incubators, can solve problems such as stop growth, death, and light boards that cannot adapt to the light distance required by different plant varieties, so as to eliminate the difference in nutrient concentration, ensure purity, and prevent deficiencies Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The technical solutions of the present invention will be further described below in conjunction with specific embodiments.

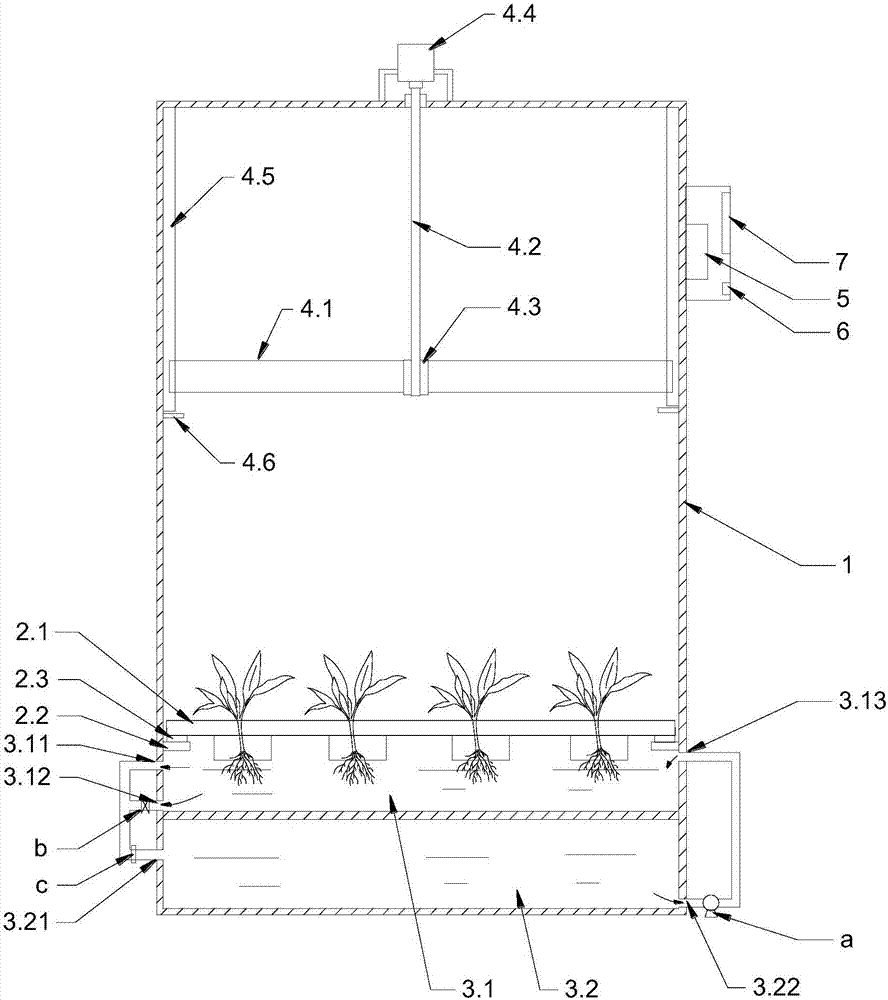

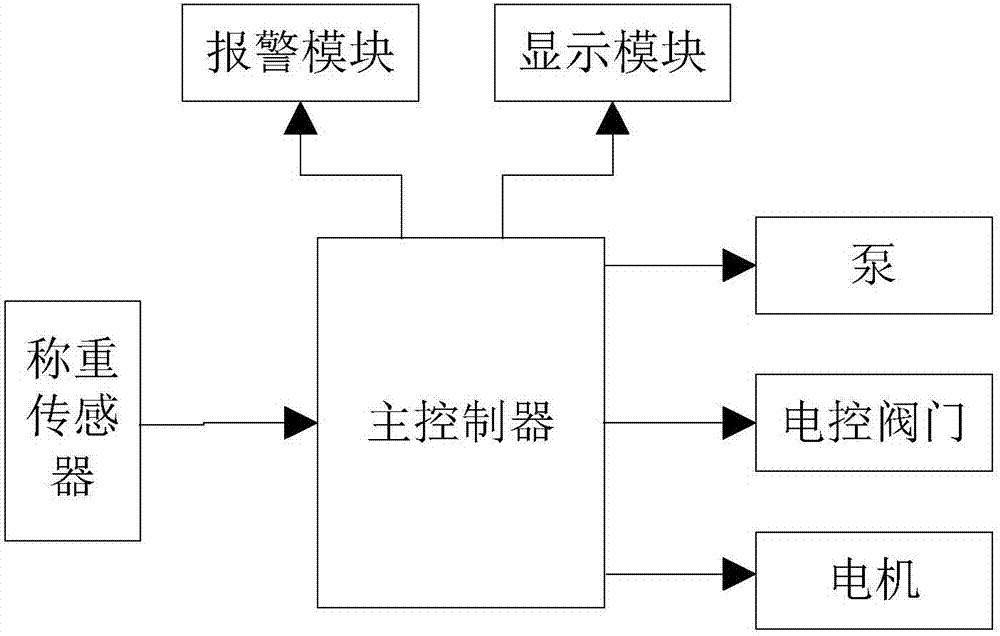

[0033] A kind of plant cultivation box, see attached figure 1 , including a box body 1, a planting plate weighing module, a culture solution circulation and root drying module, an automatic light panel height adjustment mechanism, an alarm module 6, a display module 7 and a main controller 5;

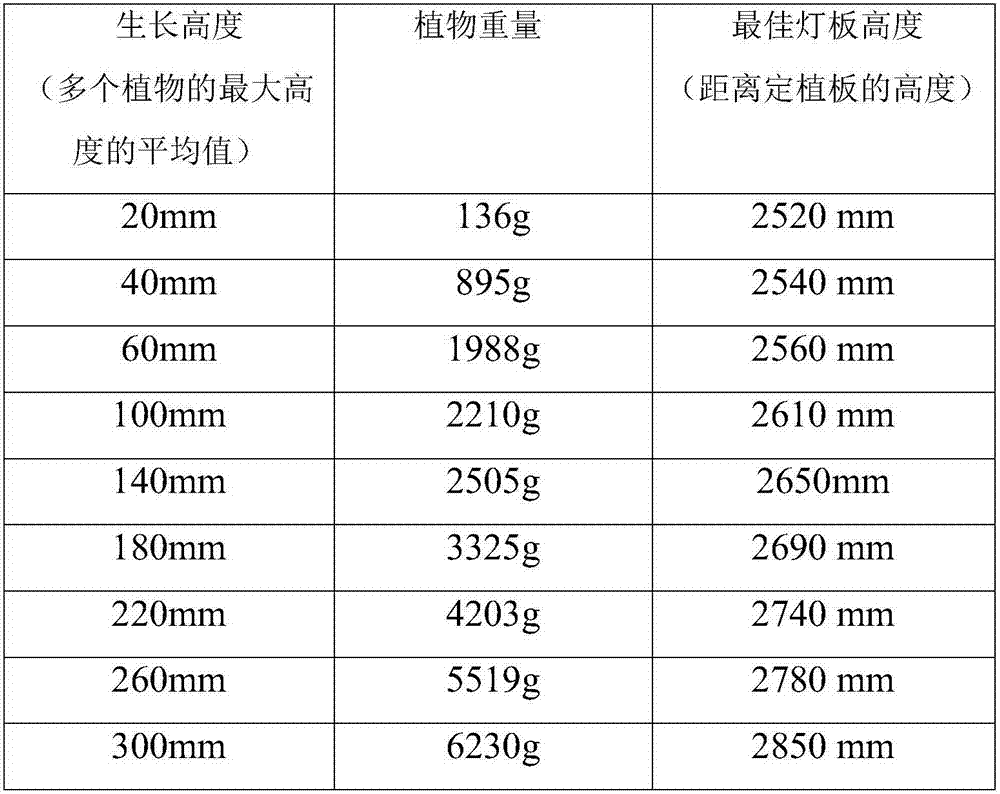

[0034] The planting plate weighing module includes a planting plate 2.1, a planting plate support 2.2, a planting plate support is set on the inner wall of the box, the planting plate is erected on the planting plate support, and a load cell 2.3 is arranged between the planting plate support and the planting plate; When in use, the plant is fixed on the planting plate, and the detection of the total weight of the planting plate and the plants on the planting plate is realized by the load cell;

[0035]The bottom of the box body 1 is provided with a culture...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com