Improved A/O integrated sewage treatment process with four internal circulations

A sewage treatment and internal circulation technology, applied in biological water/sewage treatment, water/sludge/sewage treatment, return water treatment, etc., can solve the problems of unstable effluent quality, reduced denitrification efficiency, low separation efficiency, etc. Achieve the effect of promoting simultaneous nitrification and denitrification, improving shock load resistance, and improving the efficiency of nitrogen and phosphorus removal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

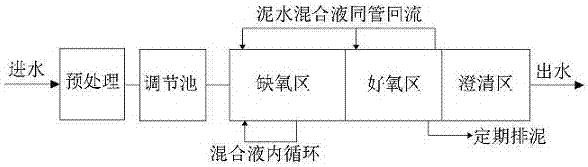

[0030] Such as figure 1 As shown, a four-inner circulation improved A / O integrated sewage treatment process includes pretreatment, regulating tank, anoxic zone, aerobic zone, and clarification zone.

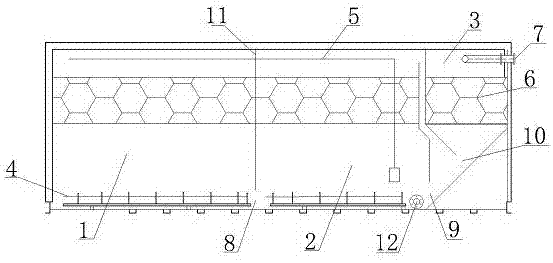

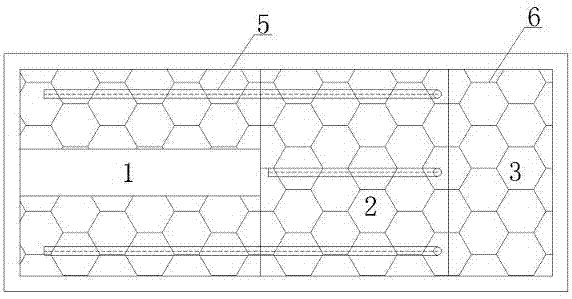

[0031] Such as figure 2 , Figure 4 As shown, a four-inner circulation improved A / O sewage treatment process equipment of the present invention includes: anoxic zone (1), aerobic zone (2), clarification zone (3), new microporous aeration hose (4 ), air stripping device (5), efficient packing (6).

[0032] A new microporous aeration hose (4) is installed in the middle of the bottom of the anoxic zone (1). The new microporous aeration hose (4) not only provides the amount of dissolved oxygen required for hypoxia, but also changes the density of the mixed liquid. Push the mixed liquid in the middle to lift up, then flow to both sides and return to the bottom through the high-efficiency packing (6) from top to bottom, so that two internal cycles are formed. The mixed solution en...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com