Preparation method of tailings autoclaved bricks

An autoclaved brick and tailings technology, applied in sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problems of reducing the expected effect of copper slag comprehensive utilization projects, complex components, environmental pollution, etc. Utilize added value, improve quality, alleviate the effect of occupying land

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

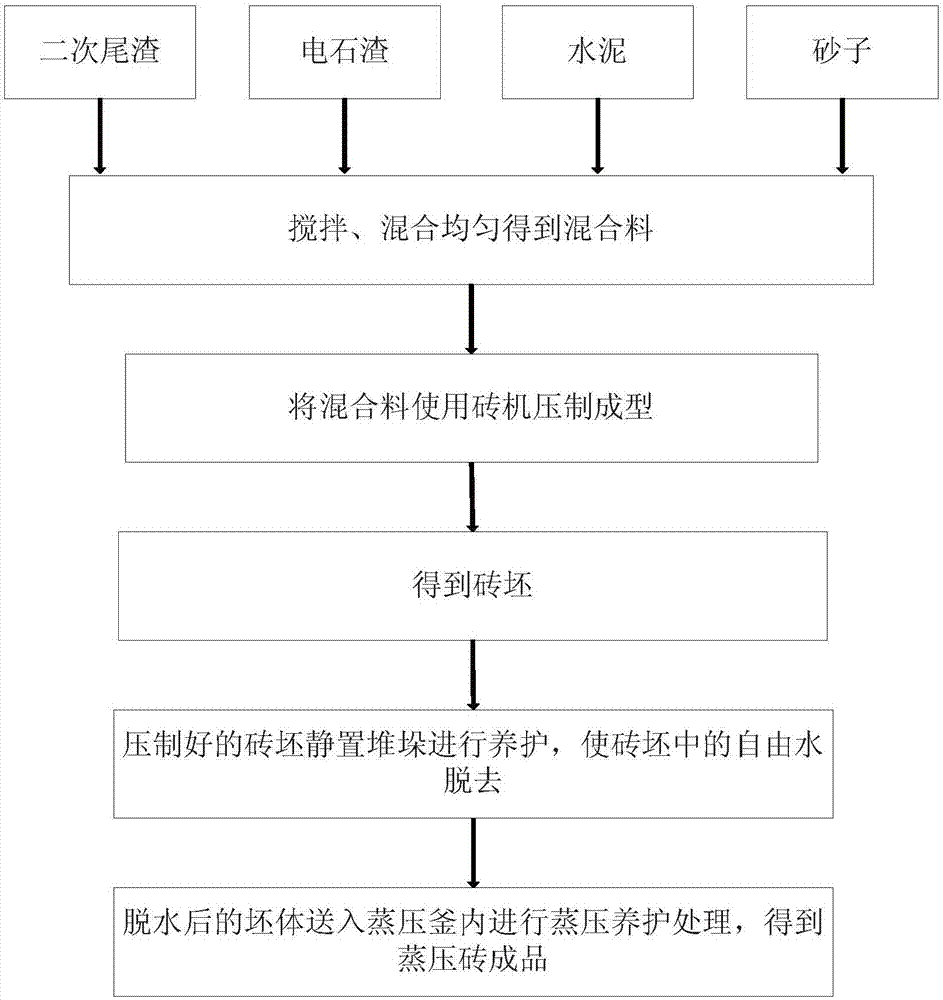

[0030] Such as figure 1 As shown, the preparation method of the tailings autoclaved brick of the present embodiment is as follows:

[0031] (1) Ingredients

[0032] Weigh various raw material components according to the ratio of parts by weight (based on dry materials), and then put them into a strong mixer.

[0033] The specific proportion is: 55 parts by weight of copper slag secondary tailings, 25 parts by weight of carbide slag, 15 parts by weight of cement, and 5 parts by weight of sand. The particle size distribution of sand is 2.5-5.0mm. SiO in secondary tailings of copper slag 2 The content is 55wt%. The secondary tailings of copper slag with particle size below 200 mesh account for more than 80wt% of the total secondary tailings of copper slag. Ca(OH) in carbide slag 2 The content is 80wt%.

[0034] (2) stirring

[0035] Stir in a strong mixer to make the materials evenly mixed, and the stirring time is 30min.

[0036] (3) Compression molding

[0037] The mi...

Embodiment 2

[0045] Such as figure 1 As shown, the preparation method of the tailings autoclaved brick of the present embodiment is as follows:

[0046] (1) Ingredients

[0047] Weigh various raw material components according to the ratio of parts by weight (based on dry materials), and then put them into a strong mixer.

[0048] The specific ratio is: 60 parts by weight of copper slag secondary tailings, 20 parts by weight of carbide slag, 15 parts by weight of cement, and 5 parts by weight of sand. The particle size distribution of sand is 2.5-5.0mm. SiO in secondary tailings of copper slag 2 The content is 65wt%. The secondary tailings of copper slag with particle size below 200 mesh account for more than 80wt% of the total secondary tailings of copper slag. Ca(OH) in carbide slag 2 The content is 85wt%.

[0049] (2) stirring

[0050] Stir in a strong mixer to make the material mix evenly, and the stirring time is 20min.

[0051] (3) Compression molding

[0052]The mixed mater...

Embodiment 3

[0060] Such as figure 1 As shown, the preparation method of the tailings autoclaved brick of the present embodiment is as follows:

[0061] (1) Ingredients

[0062] Weigh various raw material components according to the ratio of parts by weight (based on dry materials), and then put them into a strong mixer.

[0063] The specific proportion is: 65 parts by weight of copper slag secondary tailings, 20 parts by weight of carbide slag, 10 parts by weight of cement, and 5 parts by weight of sand. The particle size distribution of sand is 2.5-5.0mm. SiO in secondary tailings of copper slag 2 The content is 60wt%. The secondary tailings of copper slag with particle size below 200 mesh account for more than 80wt% of the total secondary tailings of copper slag. Ca(OH) in carbide slag 2 The content is 82wt%.

[0064] (2) stirring

[0065] Stir in a strong mixer to make the materials evenly mixed, and the stirring time is 25 minutes.

[0066] (3) Compression molding

[0067] T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com