Flame-retarding smoke inhibitor and preparation method thereof

A smoke suppressant and alkyl phosphinate technology, applied in the field of flame retardants, can solve the problems of high application cost of flame retardants, difficulty in synthesis, etc., achieve low smoke density, improve flame retardant performance, and high popularization and application value effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

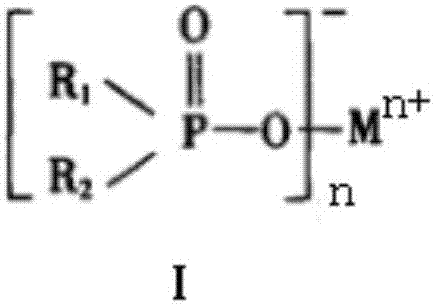

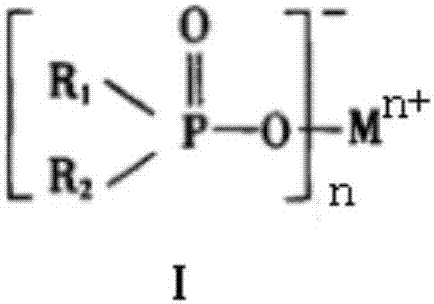

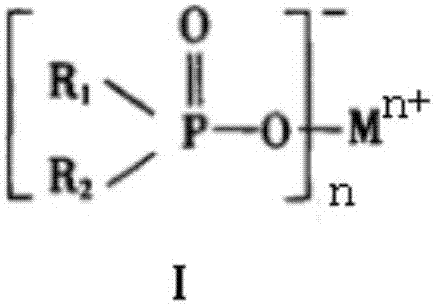

[0013] The invention provides a preparation method of a flame retardant and smoke suppressant, comprising the step of contacting the alkyl phosphinate shown in formula (I), tributyltin and tri-n-octyl phosphine oxide by heating at 200-300°C ; Wherein, in formula (I): R 1 For C1-C6 alkyl or phenyl; R 2 For C1-C6 alkyl or phenyl; M is a metal element, n is a number from 1 to 4, so that M n+ is a metal cation, where n+ represents the charge formally assigned to the cation, and n is a number from 1 to 4.

[0014]

[0015] By selecting the types of raw materials and the preparation process according to the above technical scheme, those skilled in the art can obtain the flame retardant and smoke suppressant. The flame retardant and smoke suppressant provided by the present invention can improve its flame retardant performance in applied materials on the basis of maintaining the advantages of low smoke density and no environmental hazards of phosphinate, and does not produce bri...

Embodiment 1

[0040] Preparation of flame retardant and smoke suppressant:

[0041] In parts by weight, 10 parts of alkylphosphinic acid represented by formula (I), 1 part of tributyltin and 6 parts of tri-n-octylphosphine oxide were mixed at 240°C for 20 minutes, and then kept at 260°C for 1.5h, wherein, R 1 is methyl; R 2 is phenyl, M is Al, and n is 3 to obtain flame retardant and smoke suppressant A1.

[0042]

Embodiment 2

[0044] Preparation of flame retardant and smoke suppressant:

[0045] In parts by weight, 10 parts of alkylphosphinic acid represented by formula (I), 2 parts of tributyltin and 8 parts of tri-n-octylphosphine oxide were mixed at 245°C for 25 minutes, and then kept at 270°C for 2 hours, wherein, R 1 is n-propyl; R 2 It is an isopropyl group substituted by a hydroxyl group at the 1 position, M is Al, and n is 3, and the flame retardant and smoke suppressant A2 is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com