Preparation of porous hollow carbon nitride nanotube photocatalyst and application of porous hollow carbon nitride nanotube photocatalyst in synthesis of lactic acid by photocatalytic oxidation of xylose

A technology of photocatalyst and carbon nitride, which is applied in the field of catalysis, can solve the problems of harsh reaction conditions, cumbersome control of microbial populations, and low yield, and achieve good stability, good application prospects, and quick results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

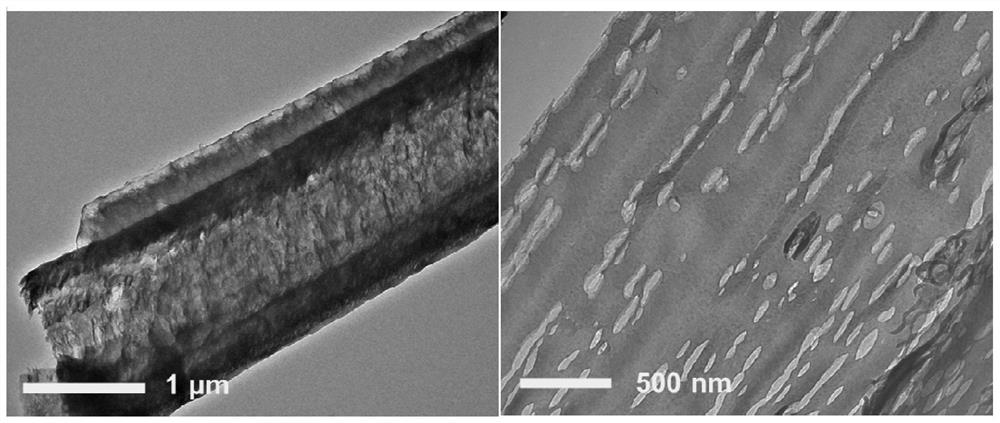

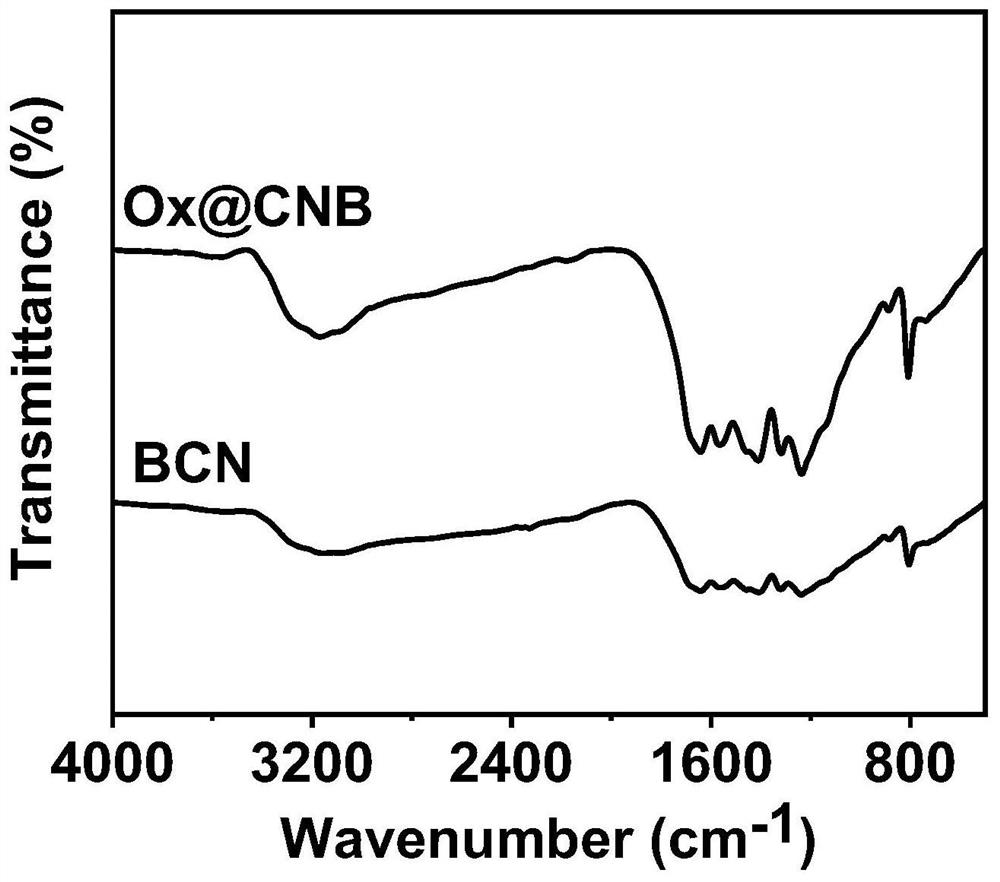

Image

Examples

Embodiment 1

[0040] (1) Accurately measure concentrated hydrochloric acid (12mol / L) with volumes of 1.0mL, 3.0mL, 5.0mL, 8.0mL, 10.0mL, and 15.0mL, and then add deionized water to prepare 200.0mL of hydrochloric acid solutions of different concentrations, Prepare different concentrations of hydrochloric acid solutions for later use;

[0041] (2) Accurately weigh 2.0 g of melamine and measure 10.0 mL of the hydrochloric acid solution configured in step (1) and add them to a polytetrafluoroethylene-lined reaction kettle, and stir evenly at room temperature;

[0042] (3) After the product obtained in step (2) was hydrothermally treated at 180°C for 10 hours, it was suction filtered to a neutral system solution, placed in a vacuum drying oven, and dried under vacuum at 60°C for 6 hours.

[0043] (4) Calcining the product obtained in step (3) for 2.0 hours at 500.0° C. in an atmosphere of nitrogen, and then grinding the obtained solid;

[0044] (5) Grinding the product obtained in step (4) at ...

Embodiment 2

[0046] (1) Accurately measure concentrated hydrochloric acid (12mol / L) with a volume of 10.0mL, then add deionized water to prepare 200.0mL of hydrochloric acid solutions of different concentrations, and prepare hydrochloric acid solutions of different concentrations for use;

[0047] (2) Accurately weigh 2.0 g of melamine and measure 10.0 mL of the hydrochloric acid solution configured in step (1) and add them to a polytetrafluoroethylene-lined reaction kettle, and stir evenly at room temperature;

[0048] (3) After the product obtained in step (2) is hydrothermally treated at 130°C, 150°C, and 200°C for 10 hours, it is suction filtered to a neutral system solution, placed in a vacuum drying oven, and vacuumized at 60°C. Dry for 6h.

[0049] (4) Calcining the product obtained in step (3) for 2.0 hours at 500.0° C. in an atmosphere of nitrogen, and then grinding the obtained solid;

[0050] (5) Grinding the product obtained in step (4) at a temperature of 600.0° C. in an atmosp...

Embodiment 3

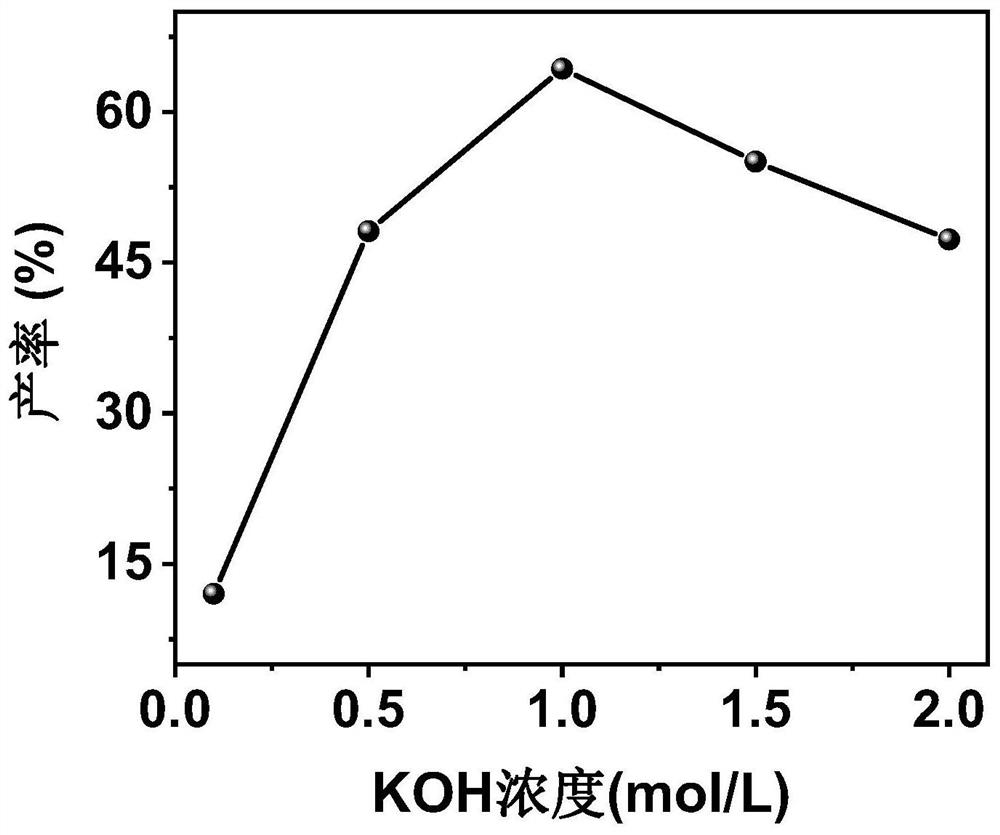

[0055] (1) Take 0.1g xylose, 10.0mL KOH solutions of different concentrations (concentrations are 0.1, 0.5, 1.0mol / L, 1.5mol / L and 2.0mol / L) and 10mL of 10.0mL concentrated hydrochloric acid in Example 1 to configure The porous hollow carbon nitride nanotube photocatalyst prepared by the solution is added into the pressure-resistant bottle;

[0056] (2) Add a magnet to the system in step (1) and stir for 30 minutes;

[0057] (3) After sealing the system in step (2), react at 50.0° C. with a 300W xenon lamp for 30 minutes, and remove the porous hollow carbon nitride nanotube photocatalyst by filtration;

[0058] (4) The filtrate obtained in step (3) is used to measure the amount of lactic acid synthesized by high-performance liquid chromatography.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com