Polyurea-based elastomer material for concrete protection and anti-seepage of hydraulic structures

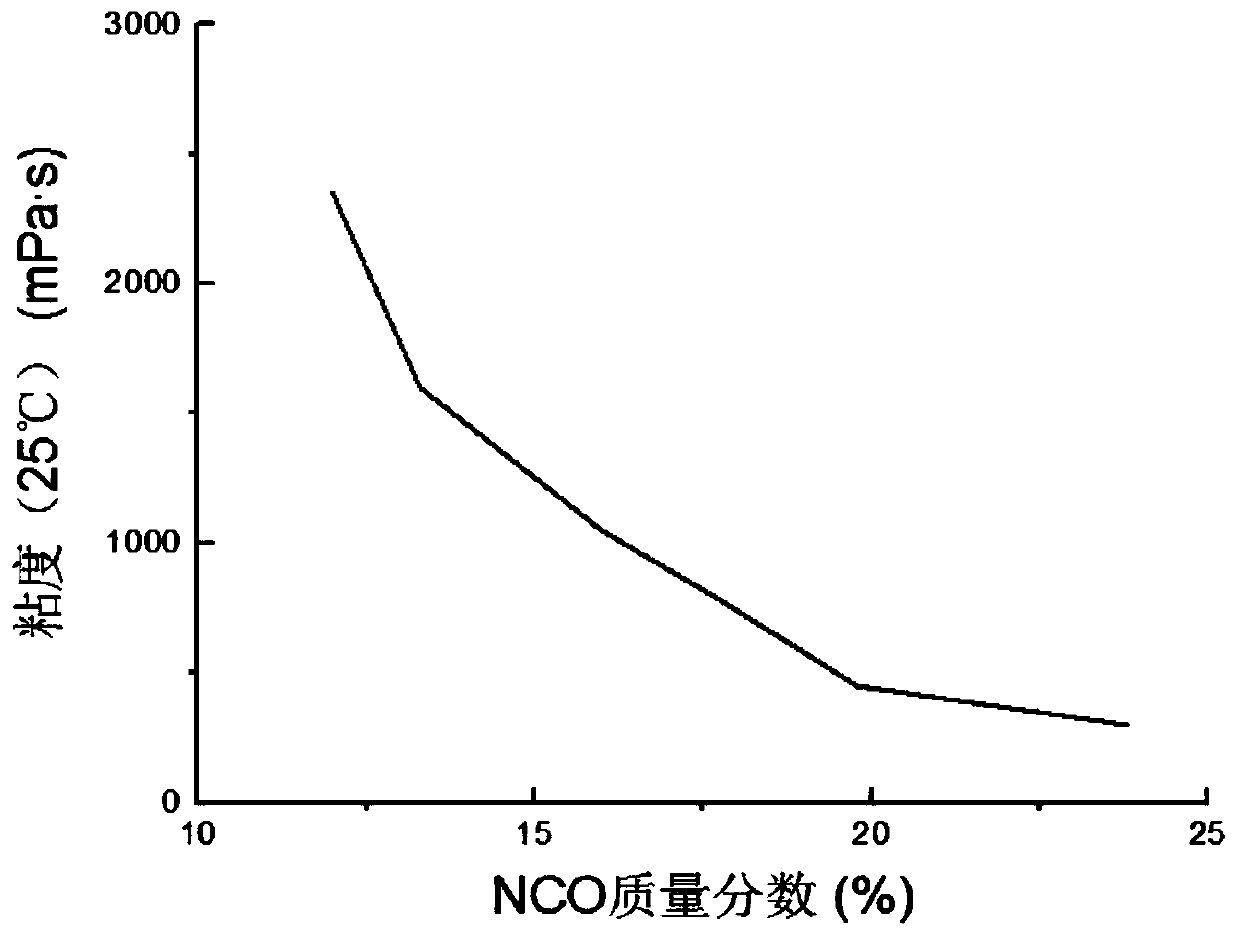

A technology of elastomer materials and hydraulic structures, applied in polyurea/polyurethane coatings, anti-corrosion coatings, coatings, etc., can solve problems such as reduced elasticity, low NCO content, poor coating density, etc., and achieve high durability , low water absorption and high elongation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0079] The polyurea-based elastomer material provided by the present invention is used in the anti-seepage embodiment of the expansion joints of water delivery tunnels and box culverts. Since the water delivery tunnel needs to be used under long-term water immersion, the surface of the substrate during construction is a wet, low-temperature base surface Therefore, the polyurea-based materials used in this field should meet the above requirements, that is, they have the characteristics of high elongation, environmental protection, high NCO content, high urea bond, high solid content, low water absorption, and super water infiltration.

[0080] Among them, the water conveyance tunnel (such as Figure 4A ) and box culverts (such as Figure 4B ) expansion joint, which is sprayed with the polyurea-based elastomer material provided in this embodiment.

[0081] Figure 4C It is a schematic diagram of the use structure of the polyurea-based anti-seepage elastomer material in this em...

Embodiment 2

[0083] The polyurea-based elastomer material provided by the present invention is applied to the anti-seepage embodiment of the aqueduct. Since the aqueduct needs to be soaked in water for a long time, exposed to the sun for a long time, and alternately with and without water repeatedly, the polyurea-based elastomer material is used in this application field. The urea-based elastomer material should meet the above requirements, that is, it has the characteristics of high NCO content, high urea bond, high solid content, anti-scouring, low water absorption, and super water infiltration.

[0084] Among them, the channel for water diversion is shown by the arrow (such as Figure 5A ) and aqueducts (such as Figure 5B ) surface, on which the polyurea-based elastomer material provided in this embodiment is sprayed.

[0085] Figure 5C It is a schematic diagram of the structure of the polyurea-based anti-seepage elastomer material used in this embodiment. It can be seen from the fi...

Embodiment 3

[0088] For the polyurea-based elastomer material provided by the present invention is applied to the spillway in alpine area (such as Figure 6A ) anti-seepage, anti-shock and wear-resistant embodiment, the spillway in the alpine region operates below -20° in winter, and withstands the erosion of high-speed water flow (20-40m / s), the polyurea-based elastomer material used in this field needs To meet the performance of freeze-thaw resistance, impact and wear resistance, it should have the characteristics of high urea bond content, high cohesive energy, high elongation, high strength, low water absorption, high-speed water erosion resistance, impact and wear resistance. When used in spillways (such as Figure 6A) is spray-coated with the polyurea-based elastomer material provided in this embodiment.

[0089] Figure 6B and 6C It is a schematic diagram of the structure of the polyurea-based anti-seepage, impact-resistant and wear-resistant, freeze-thaw resistant elastomer mate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com