Method for characterization of plant micro-nanocellulose suspensions based on atomic force microscopy

A micro-nano cellulose, atomic force microscope technology, applied in scanning probe microscopy, measuring devices, instruments, etc., to achieve the effects of good stability, real imaging, and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

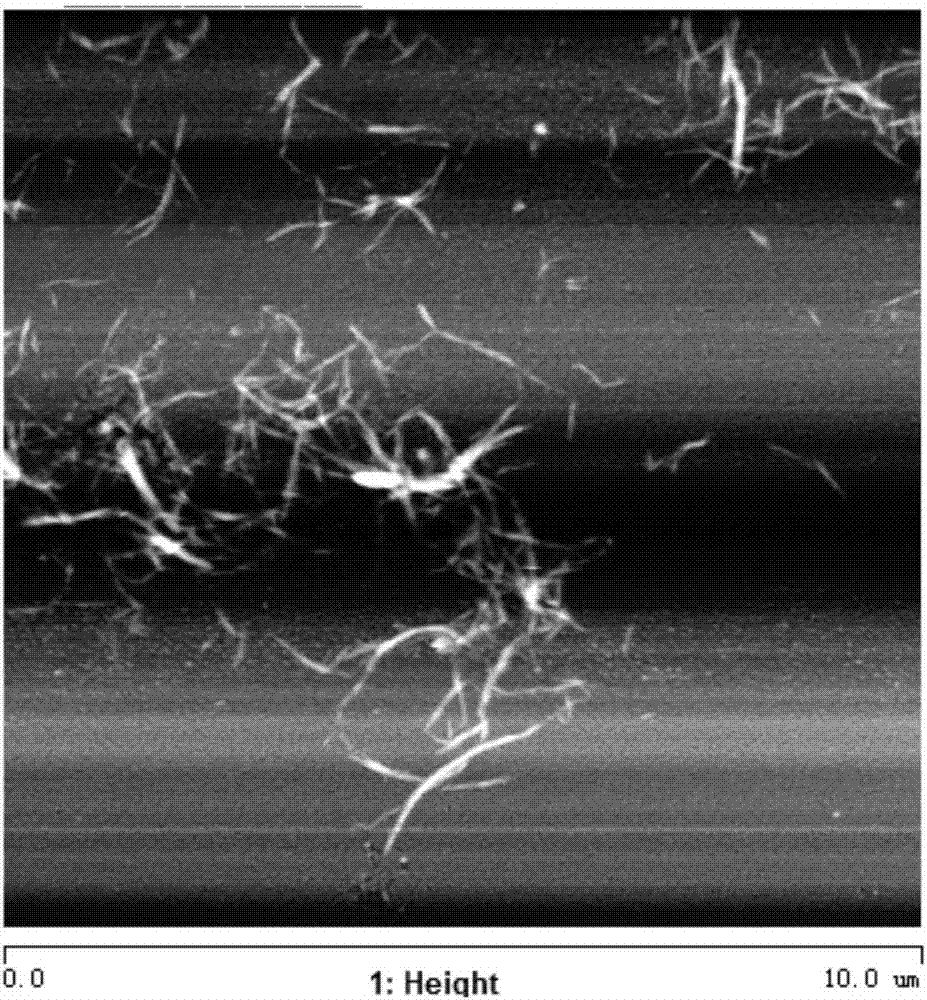

[0029] Measure 0.11 mL of 3-aminopropyltriethoxysilane, drop it into a watch glass, then add 9.9 mL of absolute ethanol, stir to mix evenly, and adjust the pH to 5 with phosphate buffer. Soak the newly peeled 5×5mm mica sheet in the solution for 4 hours, then take it out and rinse it with absolute ethanol for 5 times, and put it in an oven to dry. Use ultrapure water to adjust the concentration of plant micronanocellulose that has been pretreated and homogenized by enzymatic method to 0.4wt%, drop a drop in the center of the modified mica sheet, and rinse off unadsorbed plants with ultrapure water after 10 minutes Micro-nano cellulose, and then drop a drop of ultra-pure water in the center of the mica sheet. Finally, the prepared sample was placed on the detection table and imaged in AFM liquid mode. Imaging of plant micro-nanocellulose in suspension figure 1 As shown, the length ranges from 1 to 3 μm, and the width ranges from 10 to 40 nm.

Embodiment 2

[0031] Measure 0.3mL of γ-aminopropyltriethoxysilane and drop it into a watch glass, then add 9.7mL of acetone, stir to mix evenly, and adjust the pH to 5.5 with phosphate buffer. Soak the newly peeled 5×5mm mica sheet in the solution for 10 h, then take it out and wash it with acetone for 5 times, and put it in an oven to dry. Use ultrapure water to adjust the concentration of the plant micronanocellulose that has been pretreated and homogenized by chemical methods to 0.8wt%, drop a drop in the center of the modified mica sheet, and rinse off unadsorbed plants with ultrapure water after 20 minutes Micro-nano cellulose, and then drop a drop of ultra-pure water in the center of the mica sheet. Finally, the prepared sample was placed on the detection table and imaged in AFM liquid mode. The plant micro-nano cellulose is imaged under the suspension, with a length ranging from 0.5 to 1 μm and a width ranging from 5 to 30 nm.

Embodiment 3

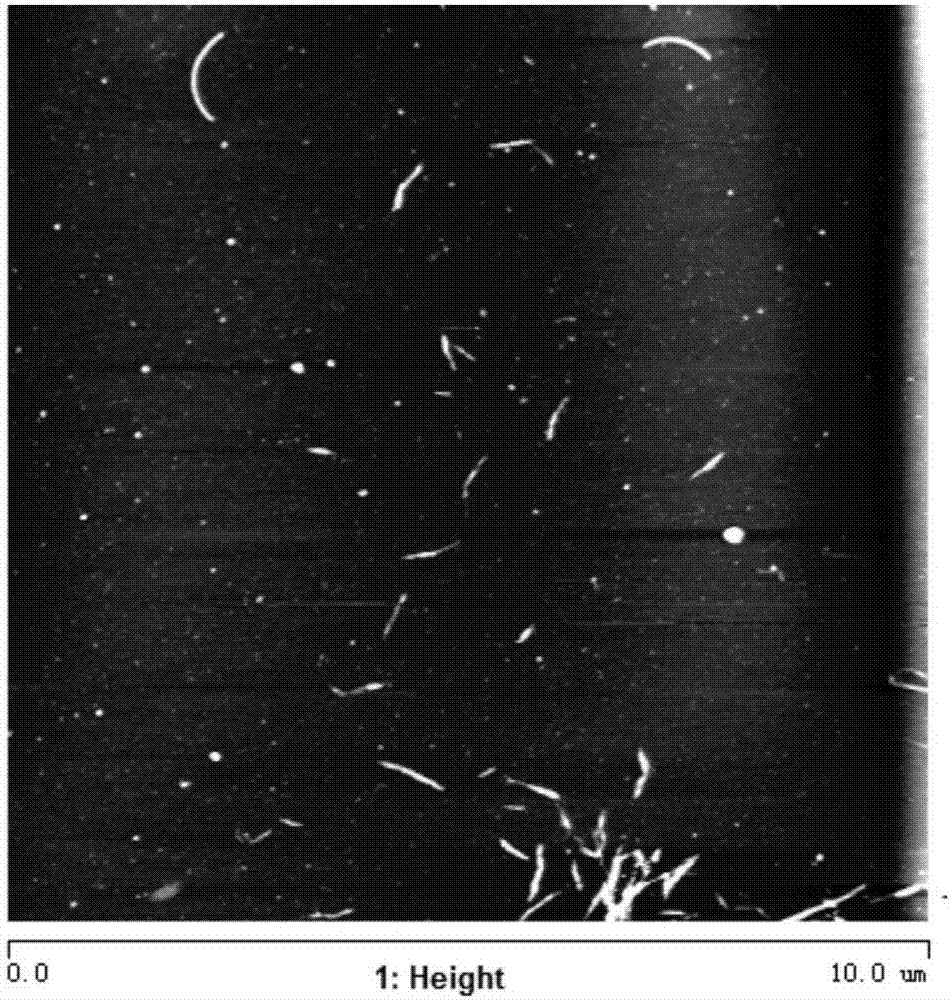

[0033] Measure 0.2 mL of diethylaminomethyltriethoxysilane, drop it into a watch glass, then add 9.8 mL of acetone, stir to mix evenly, and adjust the pH to 5.5 with phosphate buffer. Soak the newly peeled 5×5mm mica sheet in the solution for 6h, then take it out, wash it with acetone for 5 times, and put it in an oven to dry. Use ultrapure water to adjust the concentration of the plant micronanocellulose that has been pretreated and homogenized by chemical methods to 0.5%, drop a drop in the center of the modified mica sheet, and rinse off the unadsorbed plant micronose with ultrapure water after 30 minutes. nanocellulose, and then drop a drop of ultrapure water in the center of the mica sheet. Finally, the prepared sample was placed on the detection table and imaged in AFM liquid mode. Imaging of plant micro-nanocellulose in suspension figure 2 As shown, the length ranges from 0.5 to 1 μm, and the width ranges from 5 to 30 nm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com