A plastic packaging method for long line array detectors

A detector, plastic encapsulant technology, used in semiconductor/solid state device manufacturing, electrical components, circuits, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

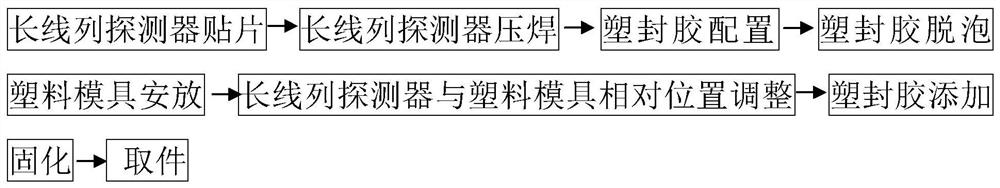

[0041] Such as figure 1 , 2 As shown, a plastic packaging method for long line array detectors comprises the following steps:

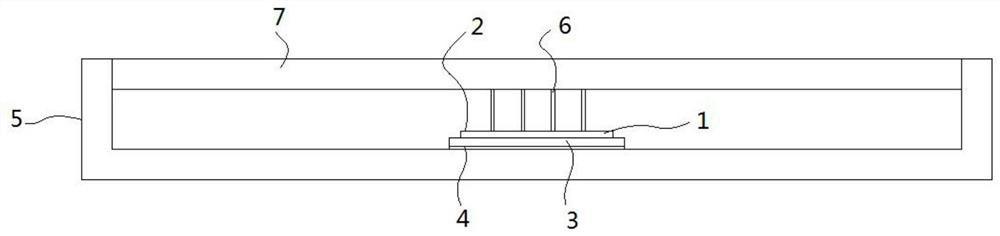

[0042] The conventional packaging of the long-line array detector 1 and the ceramic carrier 2 is completed by using the patch technology and the pressure welding technology;

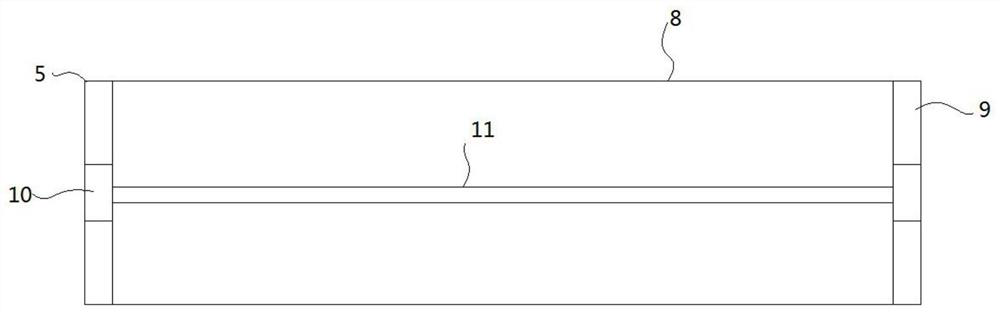

[0043] Put the packaged long line detector 1 and the ceramic carrier 2 into the plastic mold 3, exposing part of the pins 6;

[0044] By adjusting the position of the installation fixture 5, the relative position of the long line detector 1 and the ceramic carrier 2 is fixed;

[0045] Finally, the plastic sealing operation of the long-line array detector 1 is completed by adding a plastic sealant 4 to the plastic m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com